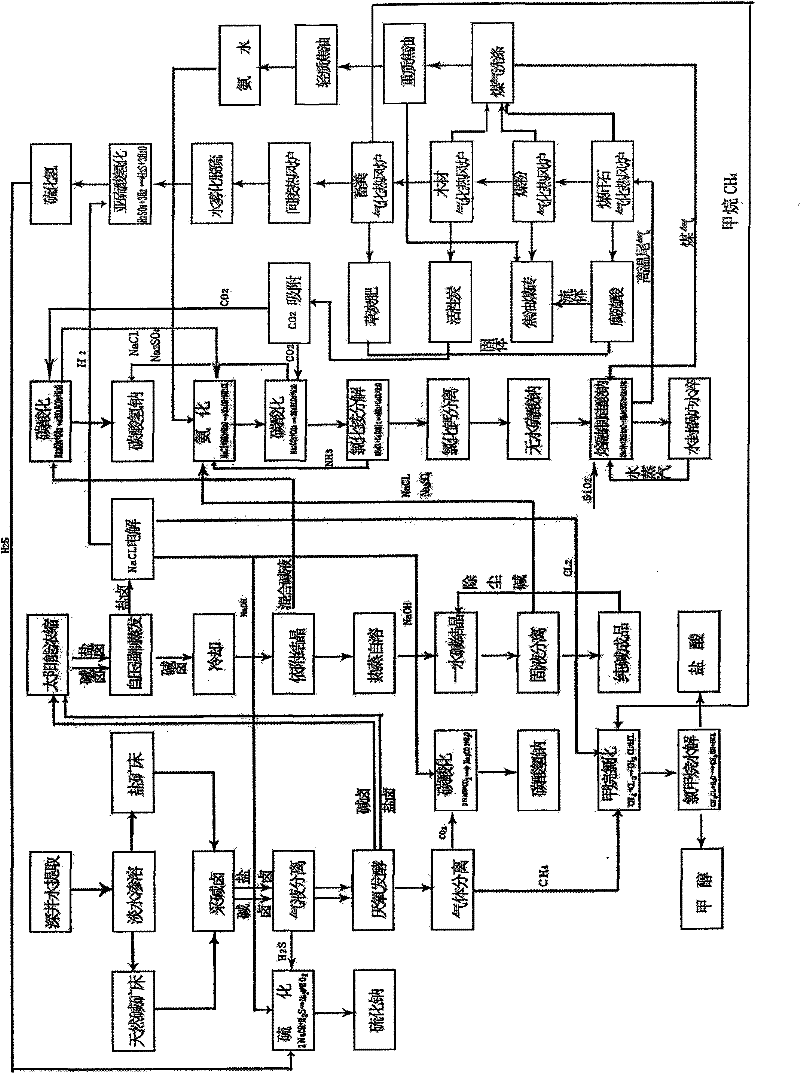

Large-scale joint alkali-making circulation process

A combined alkali production and process technology, applied in the preparation of hydroxyl compounds, organic compounds, petroleum industry, etc., can solve the problems of large production of liquid evaporation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] According to one embodiment of the present invention, the object of the present invention is achieved through the following methods.

[0039] Realize the mining of underground intersand crystals in the surface trona residual poor ore deposit by infiltration soda mining method. The specific methods include: 1. Divide the surface of the open-pit dry-mined trona residual poor ore deposit into several areas according to the terrain, Divide the divided area into several reservoirs by digging trenches or building dams. 2. Drilling deep wells from the pool, the depth of the wells should penetrate the underground impermeable layer rocks to extract underground fresh water. 3. Pour the fresh water extracted in the process (2) into the pool in the process (1), so that the fresh water leaks in the pool, and the fresh water encounters the intersand crystals in the sand layer during the infiltration process and becomes a solvent, and the fresh water Solvent dissolves the inter-sand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com