Electric dust collector

A vacuum cleaner, electric technology, applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems of unable to generate ions, dirt attached to the ion generator, temperature rise, etc., to prevent temperature rise, prolong service life, and improve durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

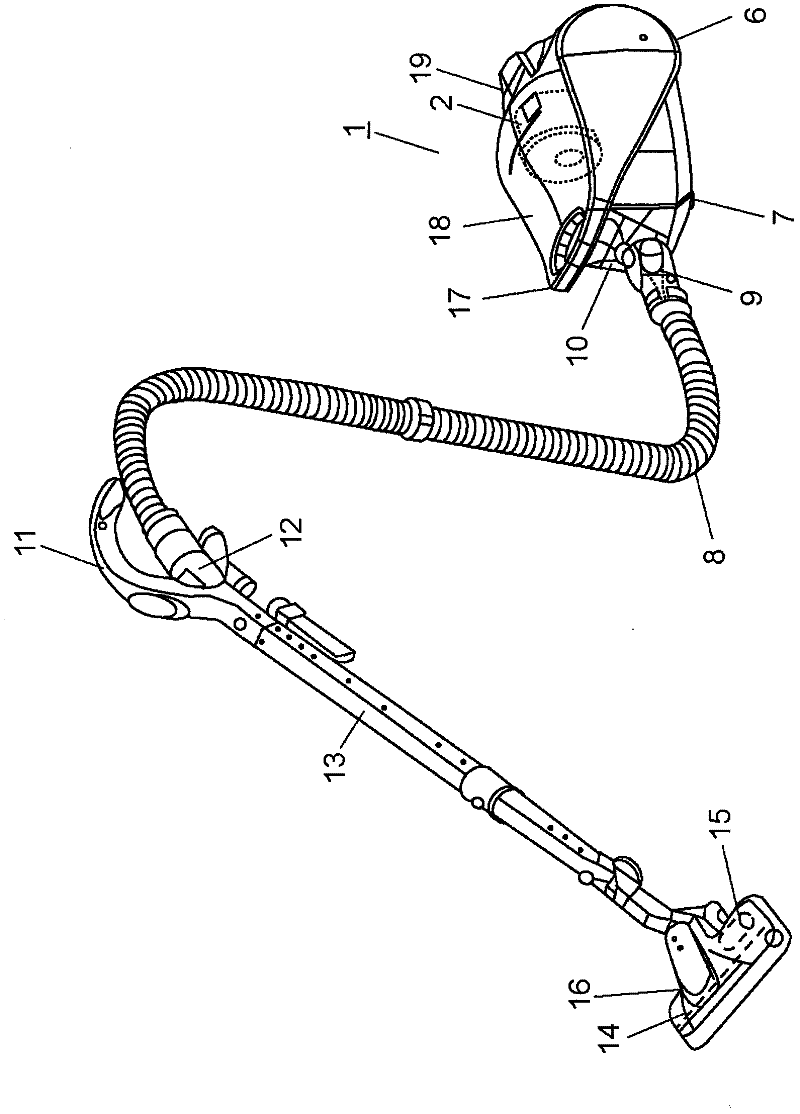

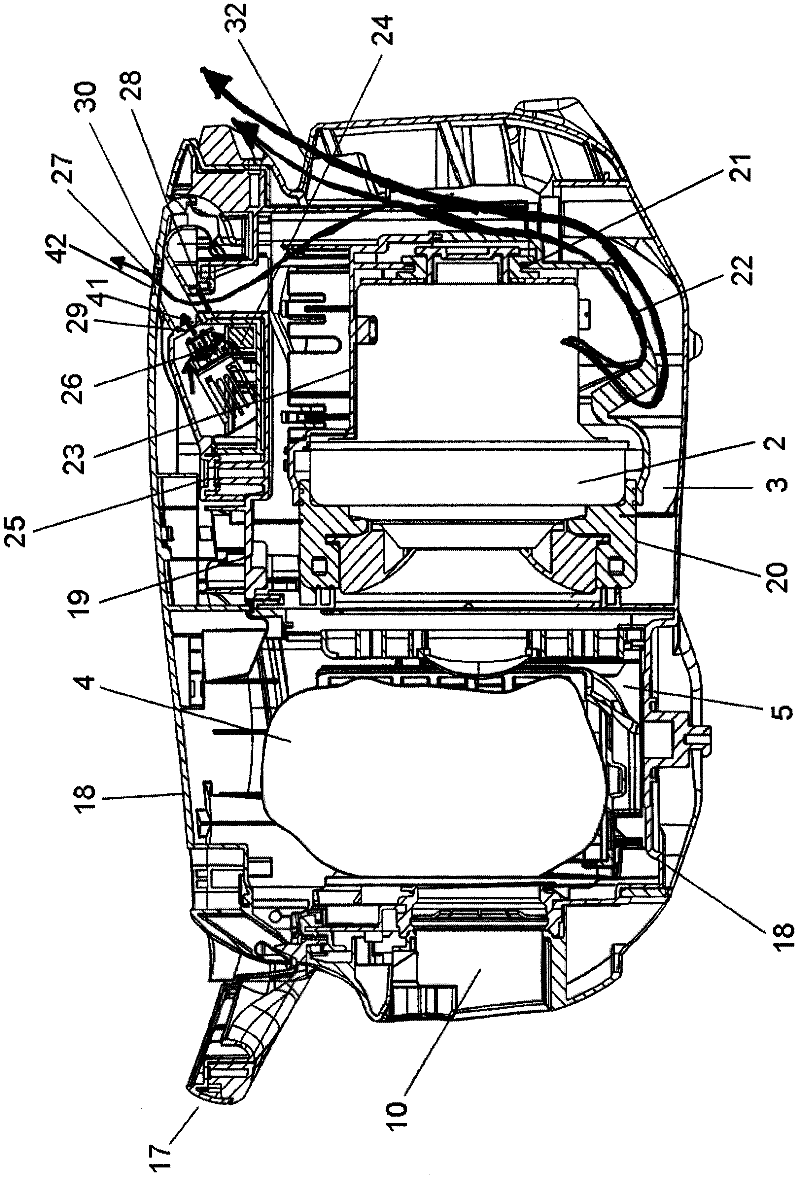

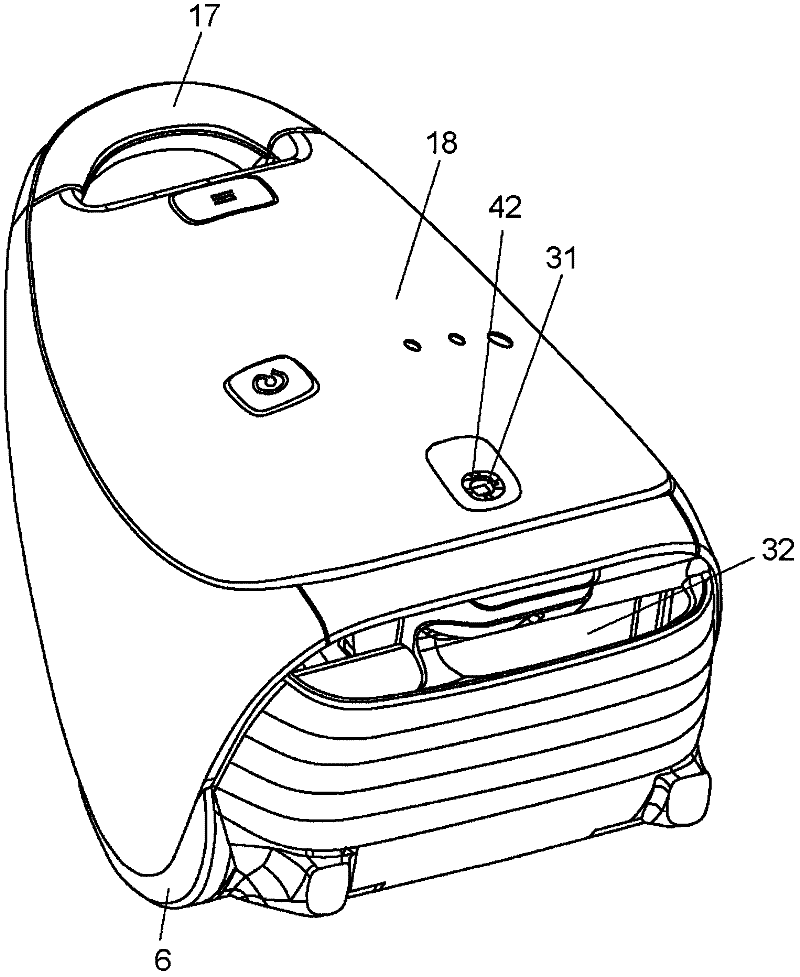

[0013] figure 1 It is an overall perspective view of an electric vacuum cleaner according to an embodiment of the present invention, figure 2 It is a sectional view of the vacuum cleaner main body of the vacuum cleaner.

[0014] like figure 1 , figure 2 As shown, in the rear part of the vacuum cleaner main body 1 of the vacuum cleaner according to this embodiment, the electric blower chamber 3 in which the electric blower 2 is built is arranged. Moreover, the dust collection chamber 5 which accommodates the detachable dust collection bag 4 is arrange|positioned at the front part of the electric vacuum cleaner main body 1. As shown in FIG. Furthermore, a pair of moving wheels 6 are rotatably attached to both sides of the rear lower part of the electric vacuum cleaner main body 1, and moving casters 7 are rotatably attached to the bottom front. Here, the electric blower 2 generates a suction wind for sucking dust and discharges an exhaust wind. The dust bag 4 is processed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com