Capacitor and method for manufacturing the same

A manufacturing method and technology for capacitors, applied to capacitors and ground terminals and its manufacture, with a pair of signal terminals, can solve the problems of increased ESL, degradation of noise removal characteristics, and deterioration of insertion loss characteristics, etc., to achieve ESL reduction , good insertion loss characteristics, and the effect of increasing the electrode cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Hereinafter, an example of a preferred mode for carrying out the present invention will be described. However, the following embodiments are merely examples. The present invention is not limited to the following embodiments.

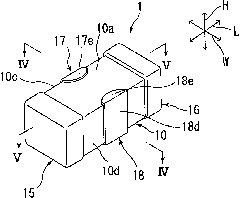

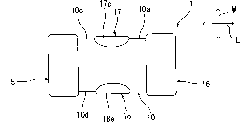

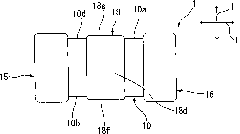

[0069] figure 1 It is a schematic perspective view of the capacitor of this embodiment. figure 2 It is a schematic plan view of the capacitor of this embodiment. image 3 It is a schematic side view of the capacitor of this embodiment.

[0070] Figure 1~3 The shown capacitor 1 of this embodiment is a capacitor used as a noise filter. like Figure 1 ~ Figure 3 As shown, the capacitor 1 has a capacitor body (ceramic body) 10 . The capacitor main body 10 is made of a dielectric. Specifically, the capacitor main body 10 is made of, for example, dielectric ceramics. Specific examples of dielectric ceramics include BaTiO 3 , CaTiO 3 , SrTiO 3 , CaZrO 3 Wait. In addition, subcomponents such as Mn compounds, Fe compounds, Cr compounds, Co ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com