Method for rapidly measuring chemical compositions of wood by utilizing near infrared spectroscopic analysis technique

A near-infrared spectroscopy and chemical composition technology is applied in the field of rapid determination of wood chemical composition by using near-infrared spectral analysis technology, which can solve the problems of consuming a lot of manpower, material resources, financial resources and time, and achieve the effect of rapid technical data support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Collect about 1000g of wood chips from 120 kinds of hardwood and coniferous wood samples. After air-drying, put each wood chip into a raw material crusher and grind them into fine powder. powder, and then put the wood powder samples into clean sealed plastic bags, after balancing the moisture, measure the chemical composition of wood by conventional methods and use near-infrared spectrometer at 12500-3600cm -1 Near-infrared spectral data are collected in the spectral range.

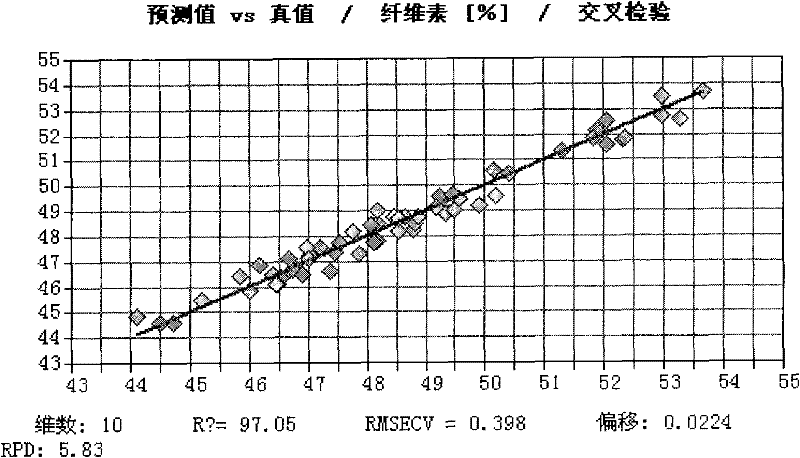

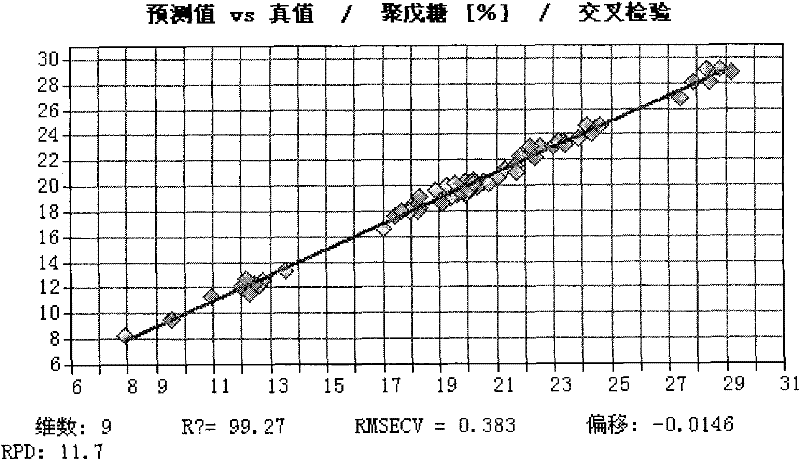

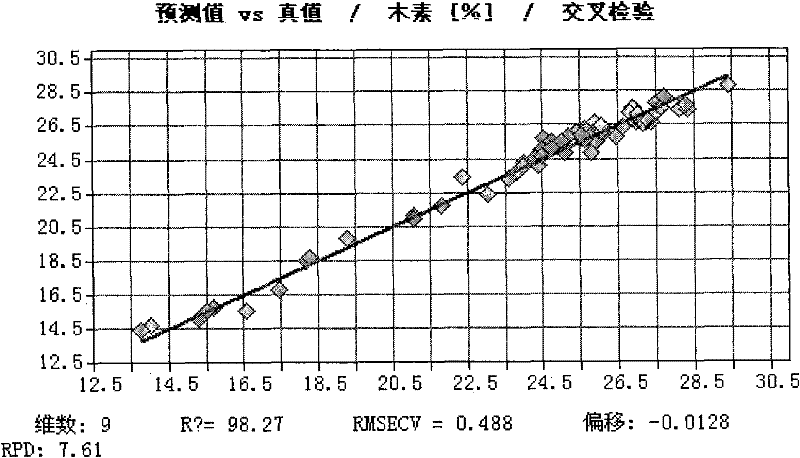

[0021] The partial least squares method in the chemometric method was used to establish the wood mathematical models corresponding to the measured values of various chemical components of wood and their near-infrared spectral data, and the model was optimized to remove some abnormal samples, so that the coefficient of determination (R 2 ) reached more than 0.93, the cross-validation root mean square deviation (RMSECV) was equivalent to the error of conventional analysis methods, and the residual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com