Energy-saving cooling tower

A cooling tower and bottom basin technology, which is applied in the field of cooling towers, can solve the problems of cooling tower power consumption, high use cost, troublesome cleaning, etc., and achieve the effect of good cooling effect, high operating efficiency and low use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

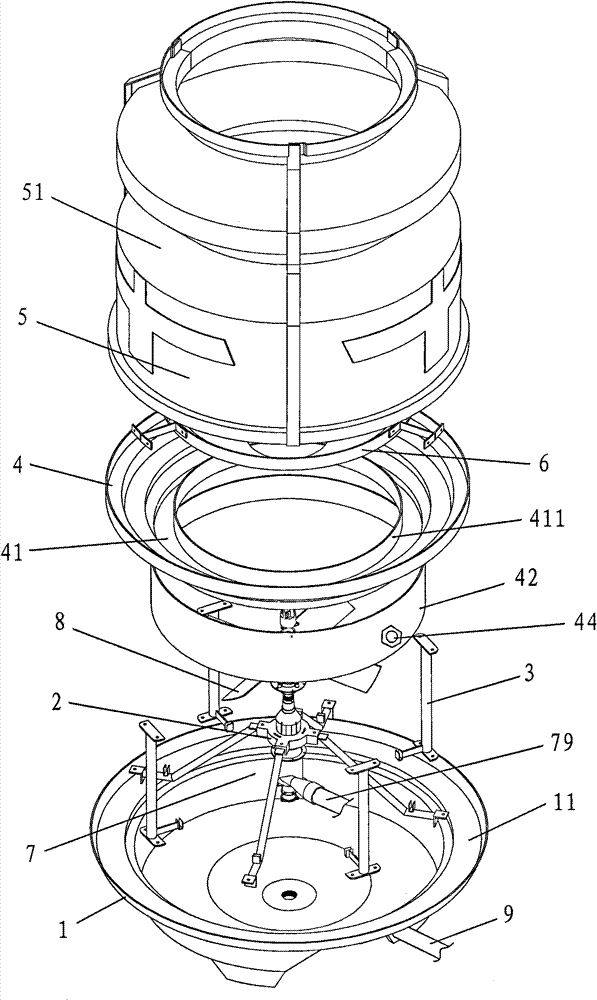

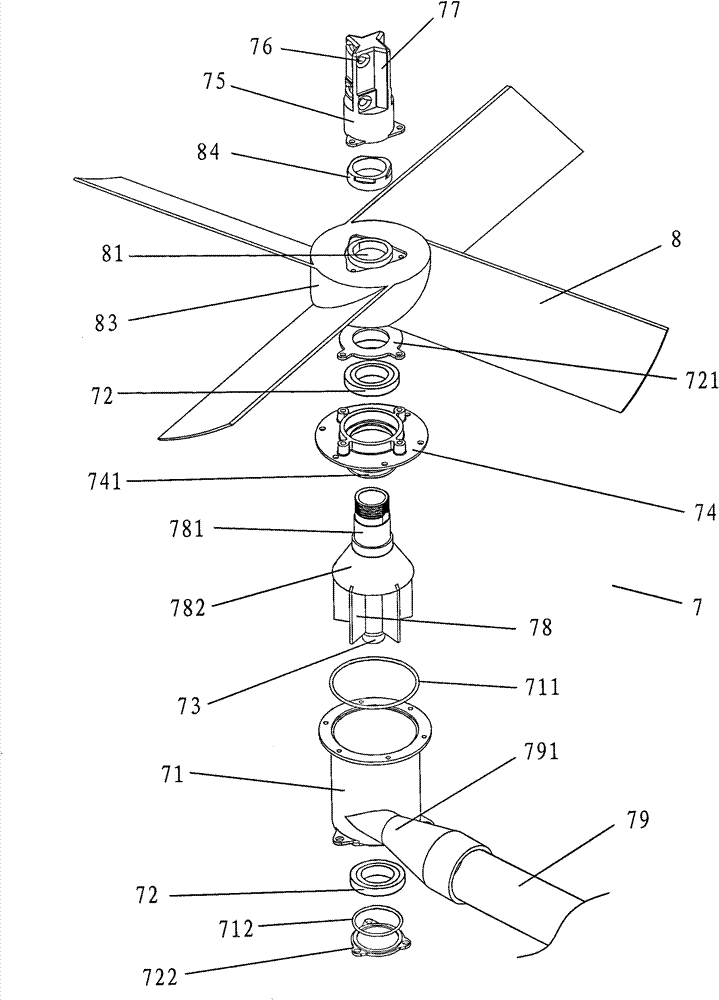

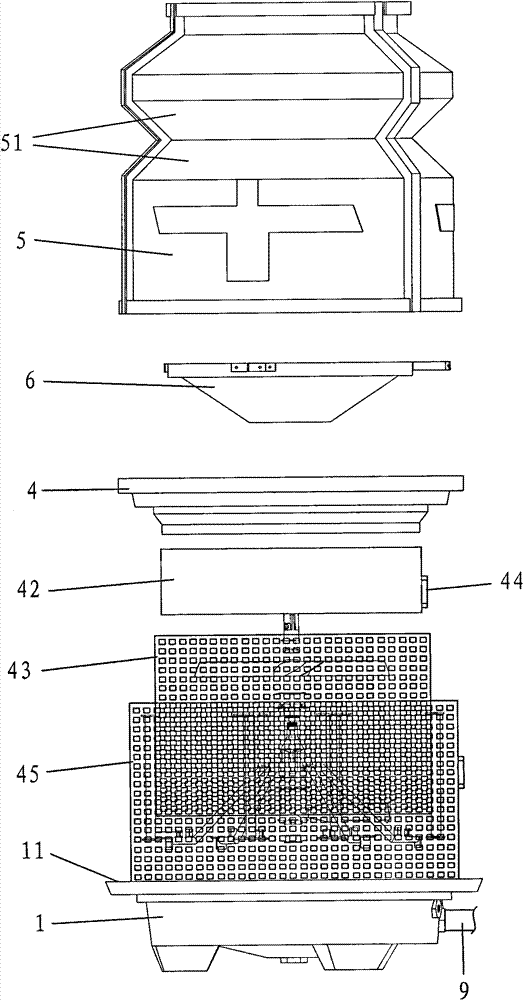

[0013] refer to Figure 1 to Figure 4 , an energy-saving cooling tower of the present invention, comprising a bottom basin 1, a support base 2 is provided in the center of the bottom basin 1, a support frame 3 is provided at the edge, and a water collection basin 4 is provided at the upper end of the support framework 3, and a water collection basin 4 is arranged on Covered with a tower shell 5, the upper part of the tower shell 5 is provided with a water collection cover 6, the support seat 2 is provided with a rotary sprinkler 7, and the rotary sprinkler 7 is equipped with a wind blade 8, and the middle part of the tower shell 5 is provided with There is a concave water collection slope 51, which can collect water well and prevent water droplets from flying out from the top. The water collection cover 6 is in the shape of a funnel and is arranged above the water collection slope 51 to play the role of water collection and return . An annular sump 41 is arranged in the descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com