Beam template for building

A technology of beam formwork for construction, applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of low reuse rate, high labor intensity of operators, and low construction quality

Inactive Publication Date: 2011-09-21

吴方伯

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because the traditional wooden formwork for construction consumes a lot of forest resources in production and use, the recycling rate is low, it consumes a lot of material and manpower, and at the same time it causes serious harm to the environment of our country.

Traditional steel formwork has problems such as heavy weight, low reuse rate, difficult disassembly and assembly, high labor intensity for operators, and low construction quality. Combined steel formwork has disadvantages such as small blocks, many joints, and weak rigidity.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

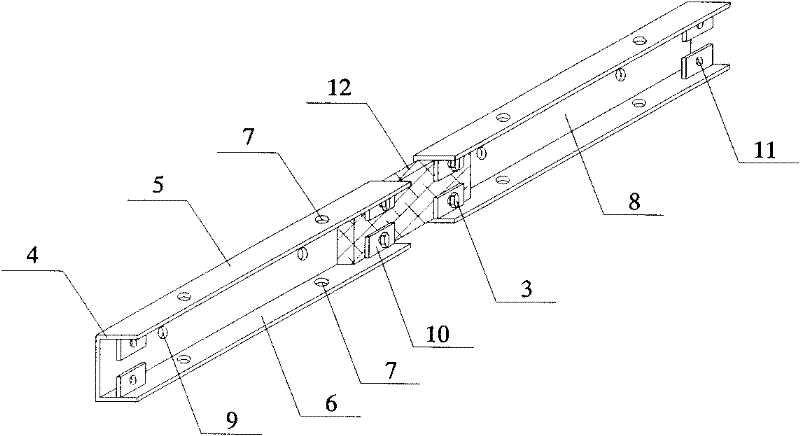

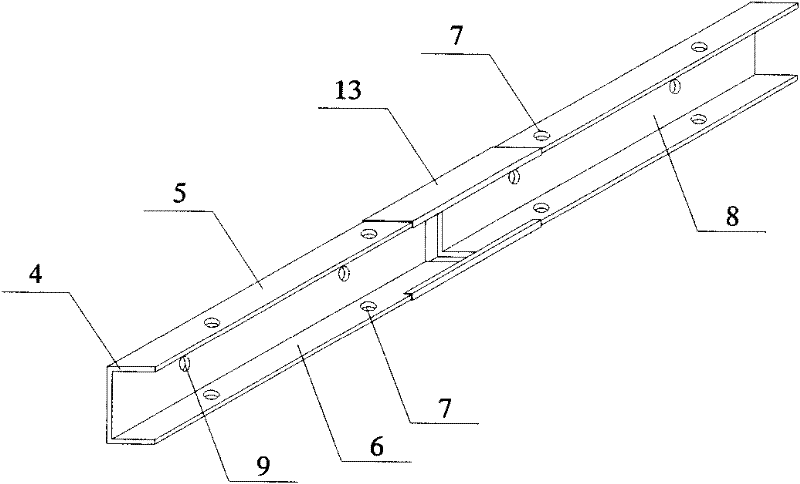

The invention discloses a beam template for a building. The beam template for the building comprises a bottom template (1) and lateral templates (2), wherein the bottom template (1) and the lateral templates (2) are formed by splicing two or more than two groove-shaped modules (4) which are connected mutually; the lateral templates (2) are tied by a transverse tie piece (14); a positioning sleeve (15) is arranged on the transverse tie piece (14); holes (7) are formed on a top plate (5) and a bottom plate (6) of the modules (4); and holes (9) are formed on a lateral plate (8). When the beam template is assembled, bolts (3) or pins pass through the holes (7) on the modules (4), and the two adjacent modules (4) are connected to form the bottom template (1) and the lateral templates (2); and the transverse tie piece (14) passes through the holes (9) on the modules (4) to tie the lateral templates (2) to form the integral beam template for the building. The integral beam template for the building has high rigidity, high bearing capacity, long service life and simple constructional processes, the modules (4) can be produced mechanically, and the quality of construction is convenient to control.

Description

beam formwork for building Technical field: The invention relates to the field of building construction, in particular to a beam template for building. Background technique: Since the 1990s, my country's building structure system has developed greatly. A large number of high-rise buildings and super high-rise buildings have been built, and large-scale infrastructure, urban transportation, and expressways have developed rapidly. These modern large-scale building systems require high engineering quality and complex construction techniques. Therefore, building construction technology must be greatly improved. Similarly, new requirements have been put forward for formwork technology. Advanced formwork technology must be used to meet the requirements of modern construction engineering. Because the traditional wooden formwork for construction consumes a lot of forest resources in production and use, the recycling rate is low, it consumes a lot of material and manpower, and at t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04G13/04

Inventor 周绪红吴方伯徐静张明陈伟

Owner 吴方伯

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com