Method for preparing biomass molded coal

A biomass and briquette technology, applied in the fields of biofuel, waste fuel, petroleum industry, etc., can solve the problems of difficulty in forming coal alone, insufficient strength of briquette, poor waterproofness, etc., to meet long-distance transportation and open storage, The effect of increasing the temperature and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] In another specific embodiment of the present invention, a kind of preparation method of binderless biomass briquette is provided, comprising:

[0067] Crushing raw coal and biomass;

[0068] Screen the crushed raw coal and biomass;

[0069] Then the sieved raw coal and biomass are mixed evenly according to a certain ratio;

[0070] Rapidly heat the evenly mixed mixture of raw coal and biomass to a predetermined temperature, and then hold it at this temperature for a certain period of time;

[0071] Compressing the insulated mixture of raw coal and biomass under a molding pressure with a compression molding die or a compression molding machine; and

[0072] The formed briquettes are cooled and demolded to obtain a binder-free biomass briquette product.

[0073] In the present invention, the term "binderless biomass briquette" refers to a biomass briquette formed without additional binders.

[0074] Preferably, the cooling is carried out using a chain cooler.

[007...

Embodiment 1

[0121] The plant biomass used in the biomass briquette raw material is crop straw;

[0122] The raw coal in the biomass briquette is lignite produced in Inner Mongolia.

[0123] Lignite and biomass are proportioned according to the following mass fractions, namely: 80 parts of lignite and 20 parts of biomass. Material particle size: ≤3mm; material moisture: ≤5%.

[0124] Measure the cold compressive strength of the biomass briquette obtained according to the determination method of industrial briquette cold compressive strength stipulated in T / T748-1997, and measure the water resistance of the biomass briquette obtained according to the method stipulated in MT / T749-1997 (including waterproof time).

[0125] Calorific value was determined according to the standard GB / T213-2008.

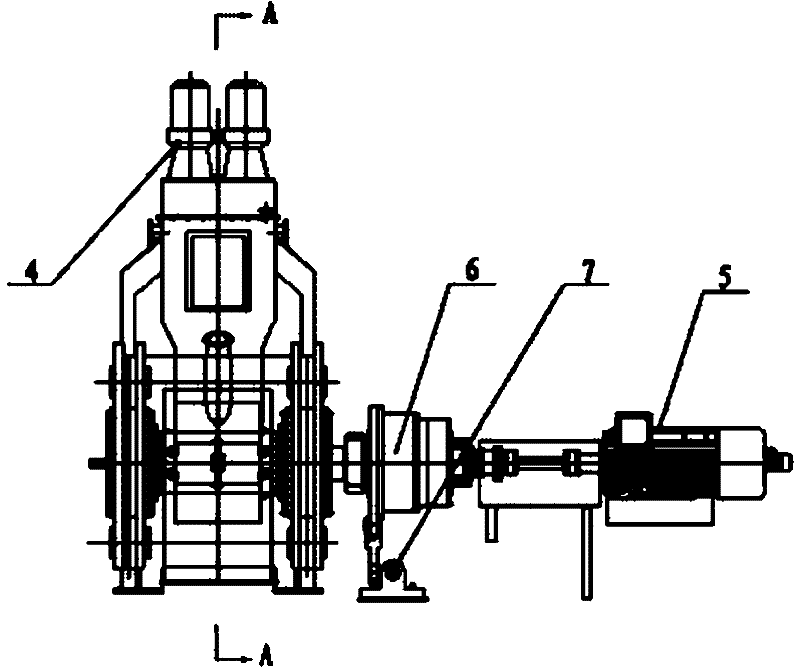

[0126]Fig. 1 is the schematic diagram of the preparation process of the biomass briquette of this embodiment of the present invention, and its technological process is: (1) lignite is sent into coal...

Embodiment 2

[0129] The plant biomass used in the biomass briquette raw material is straw;

[0130] The raw coal in the biomass briquette is long bituminous coal;

[0131] Bituminous coal and biomass are proportioned according to the following mass fractions, namely: 80 parts of long bituminous coal and 20 parts of biomass. Material particle size: ≤3mm; material moisture: ≤5%.

[0132] Measure the cold compressive strength of the biomass briquette obtained according to the determination method of industrial briquette cold compressive strength stipulated in T / T748-1997, and measure the water resistance of the biomass briquette obtained according to the method stipulated in MT / T749-1997 (including Soaking in water and re-drying strength (N / piece)).

[0133] Fig. 1 is the schematic diagram of the preparation process of the biomass briquette of this embodiment of the present invention, and its technological process: (1) long bituminous coal is sent into coal pulverizer, is ground into partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com