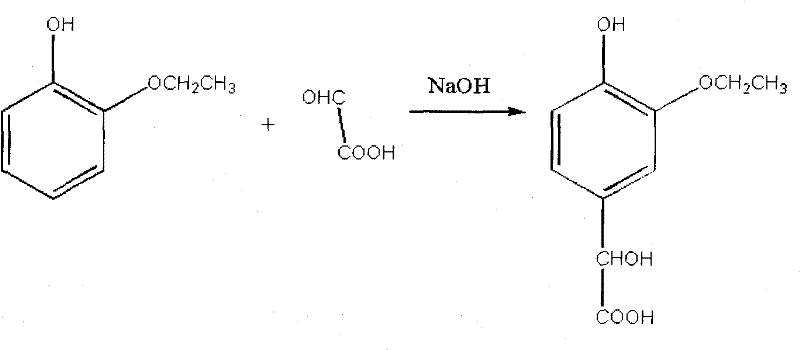

Preparation method of 3-ethoxy-4-hydroxymandelic acid used as intermediate for synthesizing ethyl vanillin

A technology of hydroxymandelic acid and ethyl vanillin, which is applied in the field of preparation of ethyl vanillin synthesis intermediate 3-ethoxy-4-hydroxymandelic acid, which can solve the problems of low product yield and long reaction time problem, achieve the effect of improving reaction selectivity, shortening reaction time and speeding up reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

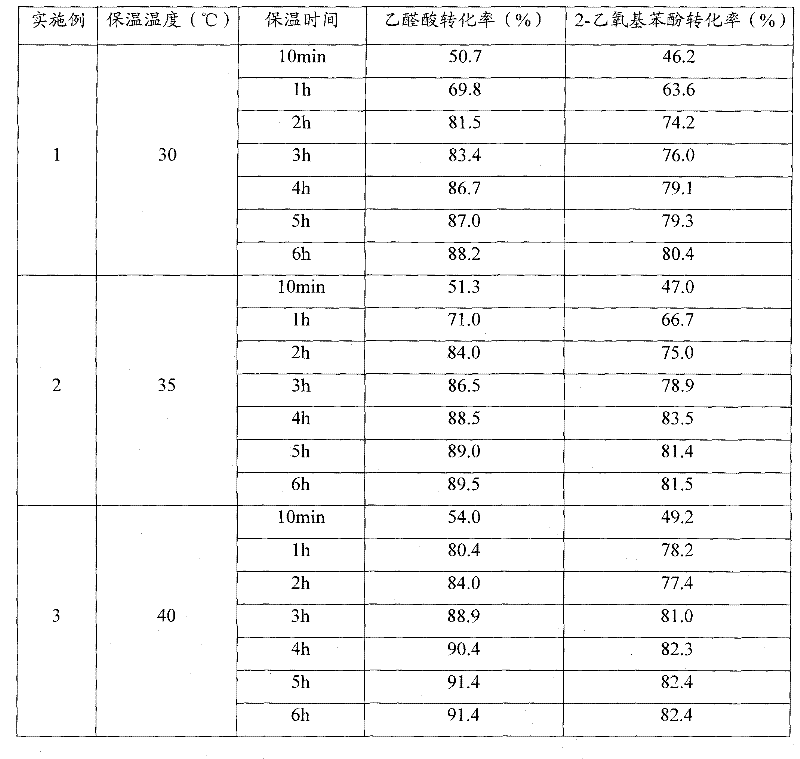

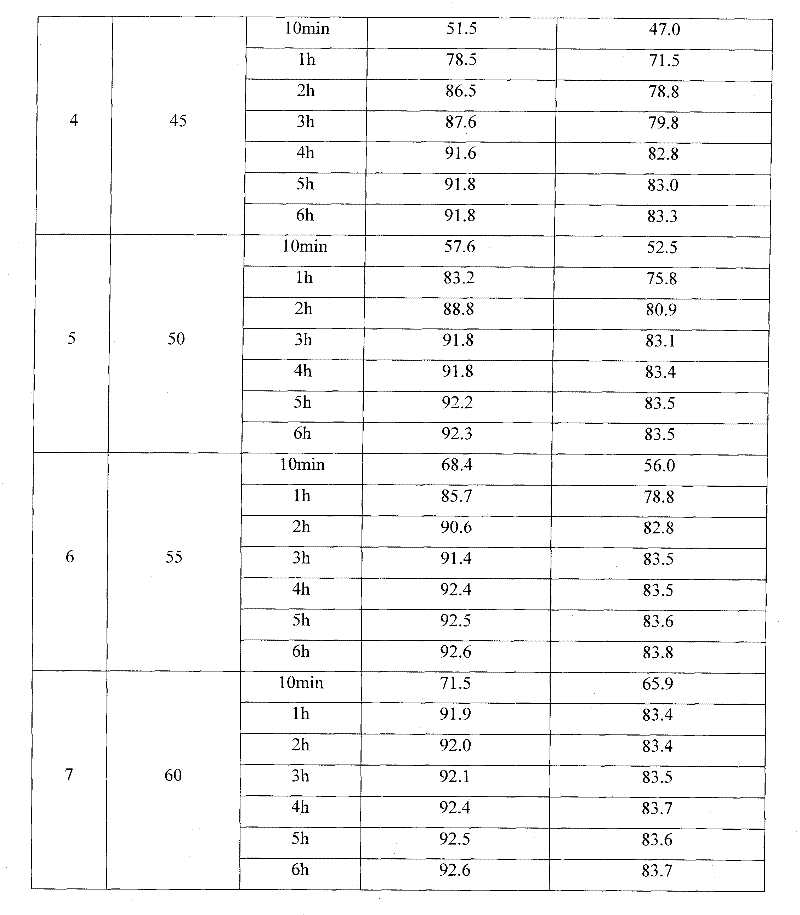

Embodiment 1~7

[0014] The synthesis of embodiment 1~7,3-ethoxy-4-hydroxymandelic acid

[0015] Method: includes the following steps:

[0016] a. Weigh 50.0g of glyoxylic acid with a mass percentage of 40%, add 83.6g of water, stir evenly at room temperature, then add dropwise 65mL of a 14.5% sodium hydroxide aqueous solution under stirring conditions, and adjust the pH to 5.0 ~5.5 to obtain glyoxylic acid solution;

[0017] b. Add 42.3g of 2-ethoxyphenol and 163.9mL of water into the three-necked flask, stir evenly, heat to 30°C, add dropwise 50mL of aqueous sodium hydroxide solution with a mass fraction of 8.3% under stirring conditions, and adjust the pH to 10-12, after 0.5 hours, the 2-ethoxyphenol alkaline solution was obtained;

[0018] c. At a temperature of 30°C, add 90 mL of the glyoxylic acid solution obtained in step a and an aqueous sodium hydroxide solution with a mass fraction of 8.3% dropwise to the 2-ethoxyphenol alkaline solution obtained in step b, respectively, for 1 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com