Preparation method of tungsten carbide nanopowder

A technology of nano-tungsten carbide and powder, which is applied in the direction of nano-structure manufacturing, carbide, nano-technology, etc., can solve the problems that it is difficult to avoid ball milling medium pollution, unfavorable industrial production promotion, long reaction time, etc., and achieve small particle size, The effect of improving the purity of the powder and reducing the degree of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

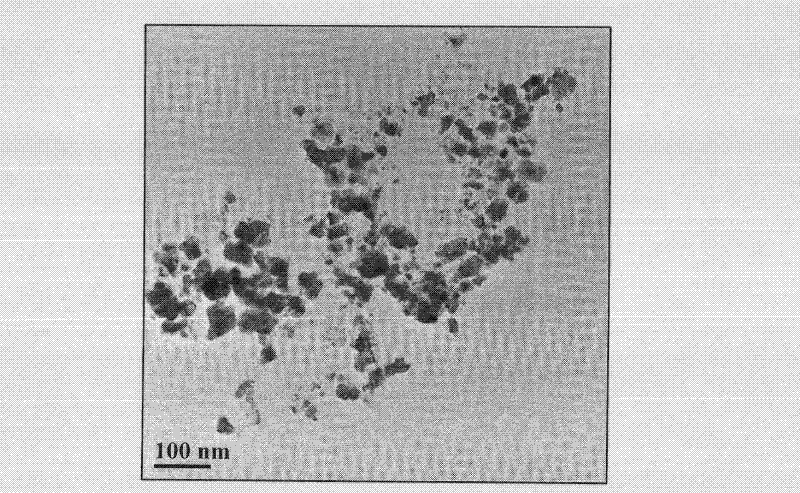

[0025] Weigh 10.0g ammonium metatungstate ((NH 4 ) 6 W 12 o 39 4H 2 (2, molecular weight 3010.35), and 17.7g of anhydrous citric acid, are dissolved in deionized water and are formulated into a clear solution. After fully stirring, the sol is processed in a water bath at 70° C., and then placed in an oven at a temperature of 100° C. The water in the sol is evaporated to form a gel, and then the temperature is raised to 200°C for 10 hours to obtain a tungsten-carbon precursor. The precursor was placed in a carbon tube furnace, and under vacuum conditions, the temperature was raised to 900°C at a rate of 5°C / min, and the nano-tungsten carbide powder was obtained after holding the temperature for 0.5 hours. figure 1 It is a transmission electron microscope photo of the powder, as shown in the figure, the average grain size of the powder is about 30nm, and the dispersion is good. The residual carbon content was measured to be 0.39 wt%.

Embodiment 2

[0027] Weigh 10.0g ammonium metatungstate (NH 4 ) 6 W 12 o 39 4H 2 O and 17.7g of anhydrous citric acid, the tungsten-carbon precursor was prepared according to the method in Example 1. The precursor was placed in a tube furnace, and the temperature was raised to 1000°C at a rate of 5°C / min under nitrogen atmosphere (nitrogen flow rate: 3L / h), and nano-tungsten carbide powder was obtained after holding for 2 hours. figure 2 It is the XRD pattern of tungsten carbide. It can be seen from the figure that the powder phase is almost pure WC phase, and the broadening of the diffraction peak is caused by the fine (nano-scale) tungsten carbide grains. The prepared powder has a residual C content of 0.32% and a particle size of 40nm.

Embodiment 3

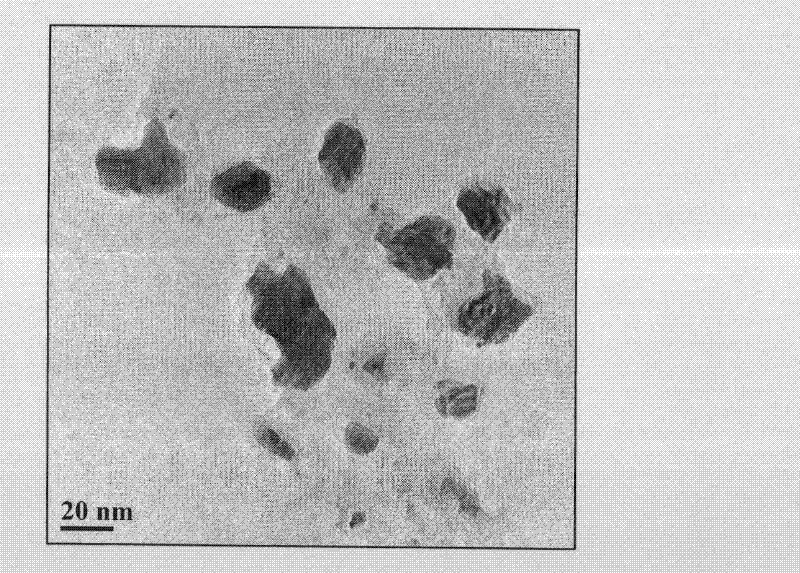

[0029] Weigh 10.0g ammonium metatungstate (NH 4 ) 6 W 12 o 39 4H 2 O and 12.5g of anhydrous acetic acid were dissolved in deionized water to prepare a clear solution. After fully stirring, the sol was processed in a water bath at 70°C, and then placed in an oven at 100°C to obtain a tungsten carbide precursor. The precursor was placed in a carbon tube furnace, and the temperature was raised to 800°C at a rate of 10°C / min under vacuum conditions for 4 hours to obtain nano-tungsten carbide powder. The prepared powder has a residual C content of 0.43% and a particle size of 25nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com