LED (light emitting diode) constant current driving circuit with current detection and LED backlight system

A constant current drive and current detection technology, applied in the electronic field, can solve the problems of no inductor and power tube, the inability to guarantee the constant current of the LED light string, and the inability to achieve system applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

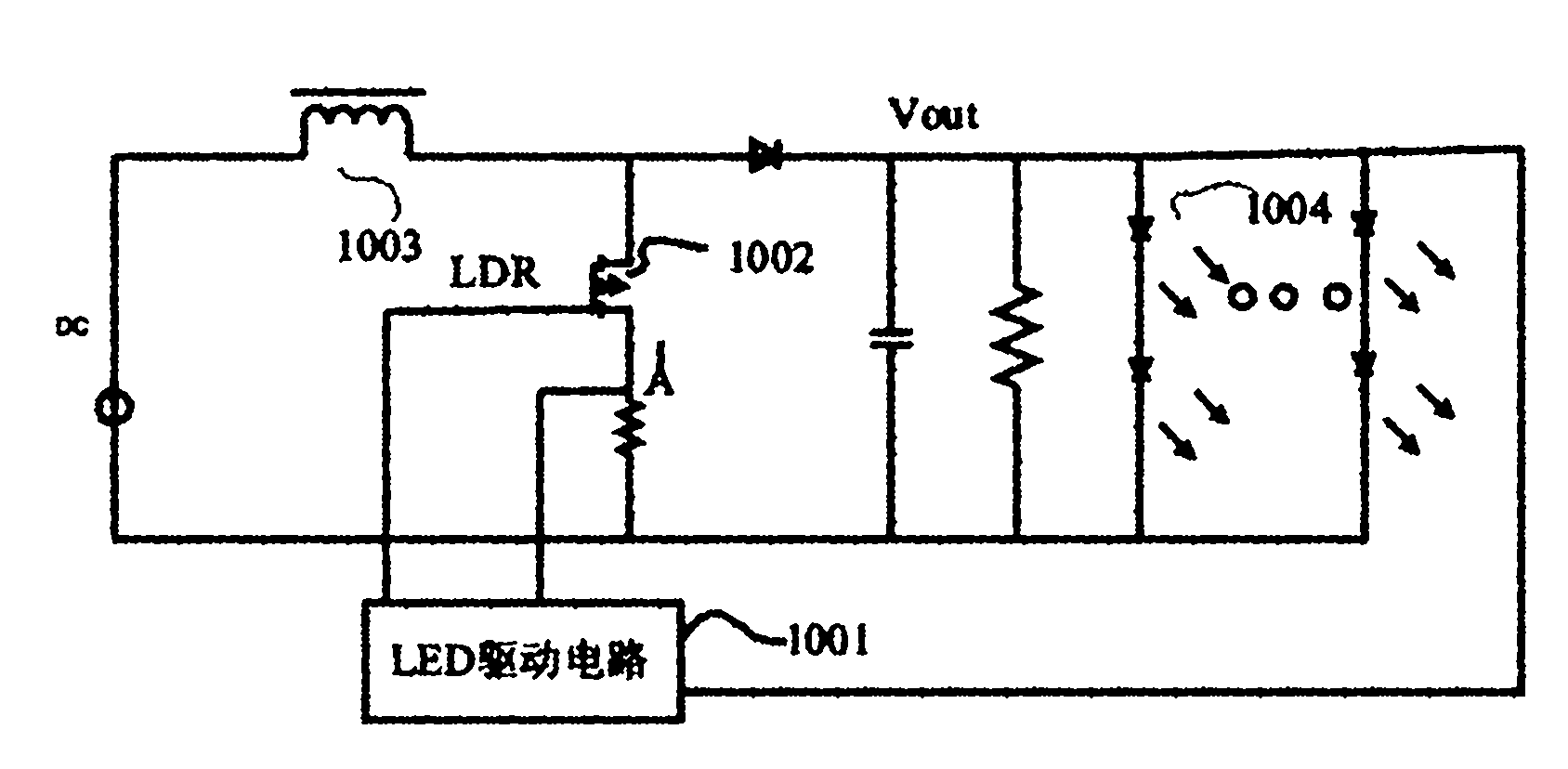

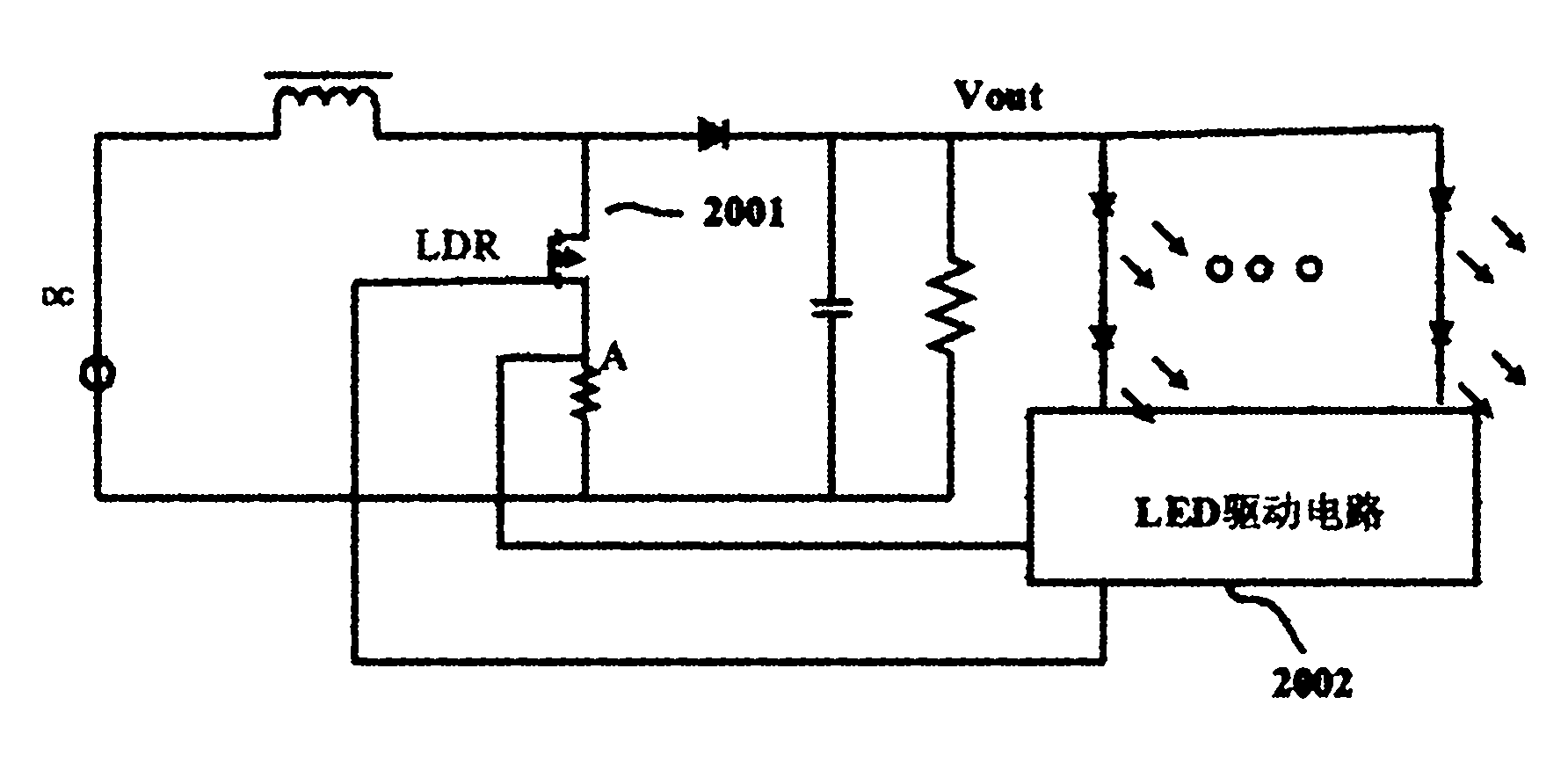

[0022] see figure 2 In the application circuit diagram of the driving circuit of the present invention, the driving circuit 2002 adjusts the duty ratio of the control signal of the switching tube by feeding back the minimum current in the LED string and combining the two loops of the inductor current value. To achieve a constant LED string current. Simultaneously detect the LED string current and output terminal voltage to judge whether there is an open circuit or short circuit in the LED light string. When there is a problem with all LED light strings, no current is output.

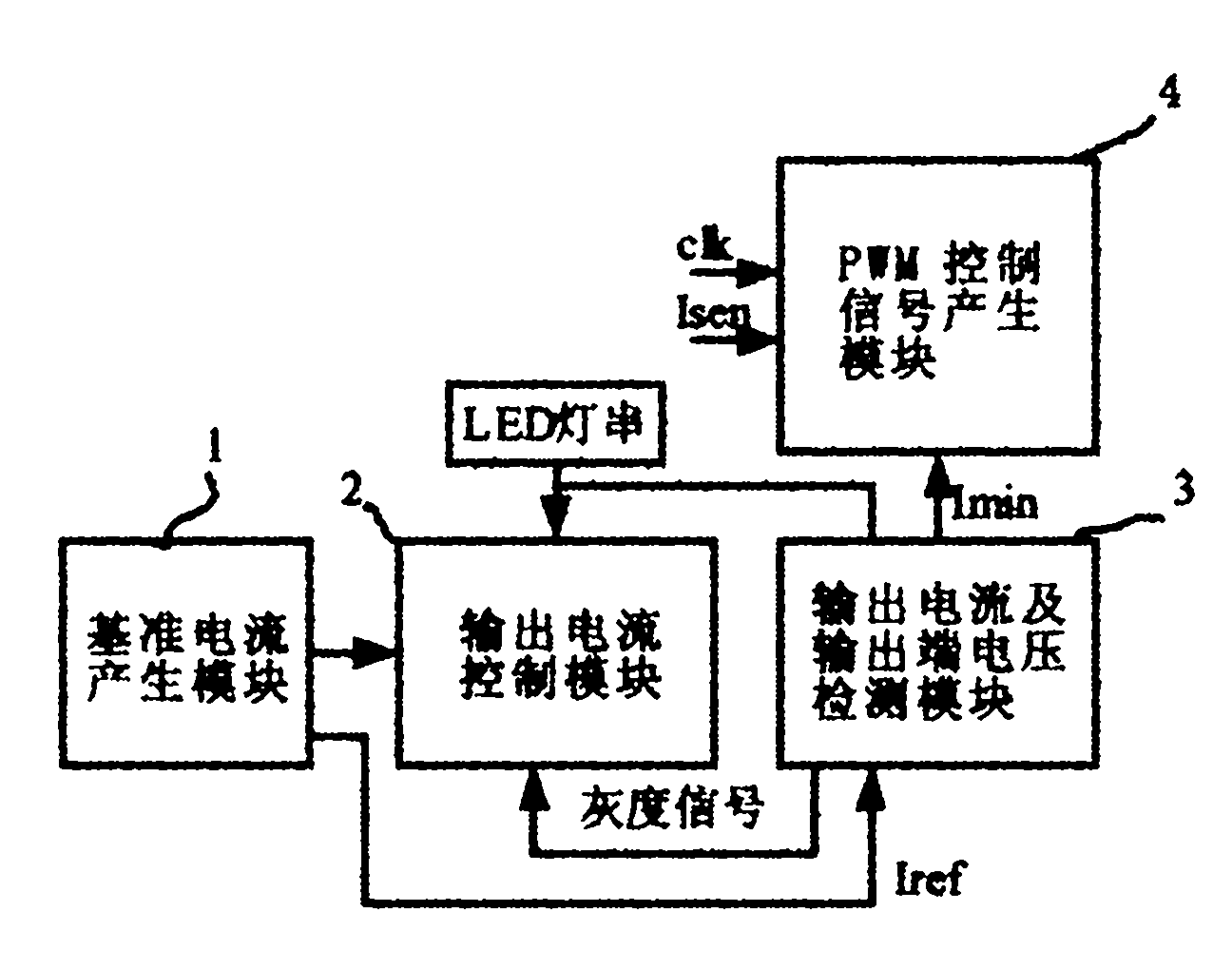

[0023] see image 3, the LED constant current drive circuit with current detection of the present invention includes a reference voltage module (not shown), a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com