Resistance-type random storage component and preparation method thereof

A resistive random storage element technology, applied in electrical components, electric solid state devices, circuits, etc., to achieve the effect of easy scientific research and industrial production, excellent memory retention characteristics, continuous cycle reading and writing ability, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

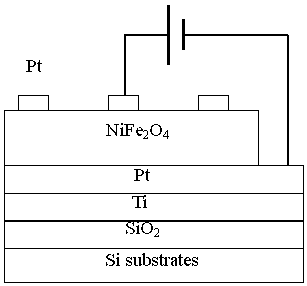

[0027] Example 1 Preparation of NiFe by Chemical Solution Deposition 2 o 4 RRAM

[0028] 1. NiFe 2 o 4 Precursor preparation: NiFe 2 o 4 The solvent of precursor solution is the mixed solution of 32ml ethylene glycol methyl ether and 16ml glacial acetic acid, and solute is 8.2030g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and 2.5392g nickel acetate tetrahydrate (C 4 h 6 NiO 4 4H 2 O), stirred at room temperature for 6 hours until completely dissolved, that is, 50ml of 0.2mol / L NiFe 2 o 4 Precursor.

[0029] 2. NiFe 2 o 4 Precursor film preparation: NiFe 2 o 4 The precursor solution is spin-coated on the Pt substrate, the spin-coating parameters are adjusted to 3000rpm, the pretreatment temperature of each spin-coating is 300°C, and the number of spin-coating is 8 times, that is, NiFe 2 o 4 precursor film.

[0030] 3. NiFe 2 o 4 Precursor film heat treatment: the prepared NiFe 2 o 4 The precursor film is heat-treated at 700°C for 1 hour to complete...

Embodiment 2

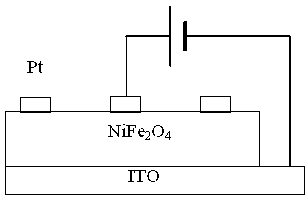

[0033] Example 2 Preparation of NiFe by chemical solution deposition 2 o 4 RRAM

[0034] 1. NiFe 2 o 4 Precursor preparation: NiFe 2 o 4 The solvent of precursor solution is the mixed solution of 32ml ethylene glycol methyl ether and 16ml glacial acetic acid, and solute is 8.2030g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and 2.5392g nickel acetate tetrahydrate (C 4 h 6 NiO 4 4H 2 O), stirred at room temperature for 6 hours until completely dissolved, that is, 50ml of 0.2mol / L NiFe 2 o 4 Precursor.

[0035] 2. NiFe 2 o4 Precursor film preparation: NiFe 2 o 4 The precursor solution is spin-coated on the Pt substrate, the spin-coating parameters are adjusted to 3000rpm, the pretreatment temperature of each spin-coating is 300°C, and the number of spin-coating is 4 times, that is, NiFe 2 o 4 precursor film.

[0036] 3. NiFe 2 o 4 Precursor film heat treatment: the prepared NiFe 2 o 4 The precursor film is heat-treated at 400°C for 1 hour to complete t...

Embodiment 3

[0039] Example 3 Preparation of NiFe by pulsed laser deposition 2 o 4 RRAM

[0040] 1. NiFe 2 o 4 Film preparation, choose NiFe 2 o 4 Ceramic target, NiFe prepared on conductive substrate Pt by pulsed laser deposition 2 o 4 film. Laser energy is 300mJ / cm 2 , the frequency is 5Hz, the air pressure is 50Pa, the temperature is 500°C, and the deposition time is 1 hour, that is, NiFe 2 o 4 thin film with a thickness of 300nm.

[0041] 2. Preparation of NiFe 2 o 4 Thin film sandwich structure: using vacuum coating and mask technology, in NiFe 2 o 4 Cu electrodes are plated on the surface of the film to prepare Cu / NiFe 2 o 4 / Pt resistive random access memory element.

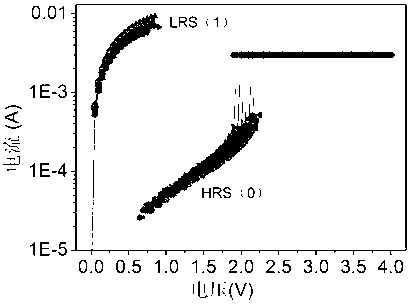

[0042] 3. Use Keithley236 analyzer to test Cu / NiFe 2 o 4 The current-voltage characteristics, cycle characteristics and retention characteristics of / Pt resistive random access memory elements. Prepared NiFe 2 o 4 Thin film storage elements and the current-voltage characteristics, cycle character...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com