Resistance-type random storage component and preparation method thereof

A resistive random storage element technology, applied in electrical components, electric solid state devices, circuits, etc., to achieve the effects of excellent high-low resistance state transition characteristics, excellent performance, excellent memory retention characteristics and continuous cycle read and write capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

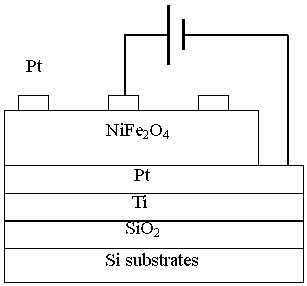

[0027] Example 1 Preparation of NiFe by Chemical Solution Deposition 2 o 4 RRAM

[0028] 1. NiFe 2 o 4 Precursor preparation: NiFe 2 o 4 The solvent of precursor solution is the mixed solution of 32ml ethylene glycol methyl ether and 16ml glacial acetic acid, and solute is 8.2030g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and 2.5392g nickel acetate tetrahydrate (C 4 h 6 NiO 4 4H 2 O), stirred at room temperature for 6 hours until completely dissolved, that is, 50ml of 0.2mol / L NiFe 2 o 4 Precursor.

[0029] 2. NiFe 2 o 4 Precursor film preparation: NiFe 2 o 4 The precursor solution is spin-coated on the Pt substrate, the spin-coating parameters are adjusted to 3000rpm, the pretreatment temperature of each spin-coating is 300°C, and the number of spin-coating is 8 times, that is, NiFe 2 o 4 precursor film.

[0030] 3. NiFe 2 o 4 Precursor film heat treatment: the prepared NiFe 2 o 4 The precursor film is heat-treated at 700°C for 1 hour to complete...

Embodiment 2

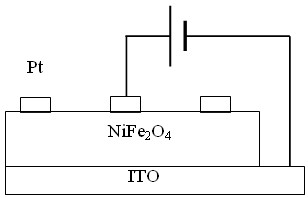

[0033] Example 2 Preparation of NiFe by chemical solution deposition 2 o 4 RRAM

[0034] 1. NiFe 2 o 4 Precursor preparation: NiFe 2 o 4 The solvent of precursor solution is the mixed solution of 32ml ethylene glycol methyl ether and 16ml glacial acetic acid, and solute is 8.2030g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and 2.5392g nickel acetate tetrahydrate (C 4 h 6 NiO 4 4H 2 O), stirred at room temperature for 6 hours until completely dissolved, that is, 50ml of 0.2mol / L NiFe 2 o 4 Precursor.

[0035] 2. NiFe 2 o 4 Precursor film preparation: NiFe2 o 4 The precursor solution is spin-coated on the Pt substrate, the spin-coating parameters are adjusted to 3000rpm, the pretreatment temperature of each spin-coating is 300°C, and the number of spin-coating is 4 times, that is, NiFe 2 o 4 precursor film.

[0036] 3. NiFe 2 o 4 Precursor film heat treatment: the prepared NiFe 2 o 4 The precursor film is heat-treated at 400°C for 1 hour to complete t...

Embodiment 3

[0039] Example 3 Preparation of NiFe by pulsed laser deposition 2 o 4 RRAM

[0040] 1. NiFe 2 o 4 Film preparation, choose NiFe 2 o 4 Ceramic target, NiFe prepared on conductive substrate Pt by pulsed laser deposition 2 o 4 film. Laser energy is 300 mJ / cm 2 , the frequency is 5Hz, the air pressure is 50 Pa, the temperature is 500°C, and the deposition time is 1 hour, that is, NiFe 2 o 4 thin film with a thickness of 300nm.

[0041] 2. Preparation of NiFe 2 o 4 Thin film sandwich structure: using vacuum coating and mask technology, in NiFe 2 o 4 Cu electrodes are plated on the surface of the film to prepare Cu / NiFe 2 o 4 / Pt resistive random access memory element.

[0042] 3. Test Cu / NiFe with Keithley 236 Analyzer 2 o 4 The current-voltage characteristics, cycle characteristics and retention characteristics of / Pt resistive random access memory elements. Prepared NiFe 2 o 4 Thin film storage elements and the current-voltage characteristics, cycle characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com