Testing device of nuclear power station digitized instrument and control system

An instrument control system and testing device technology, applied in nuclear power generation, nuclear engineering, nuclear reactor monitoring, etc., can solve the problems of few test control points, high cost, and low efficiency of manual testing, and achieve simplified connection process and clear wiring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

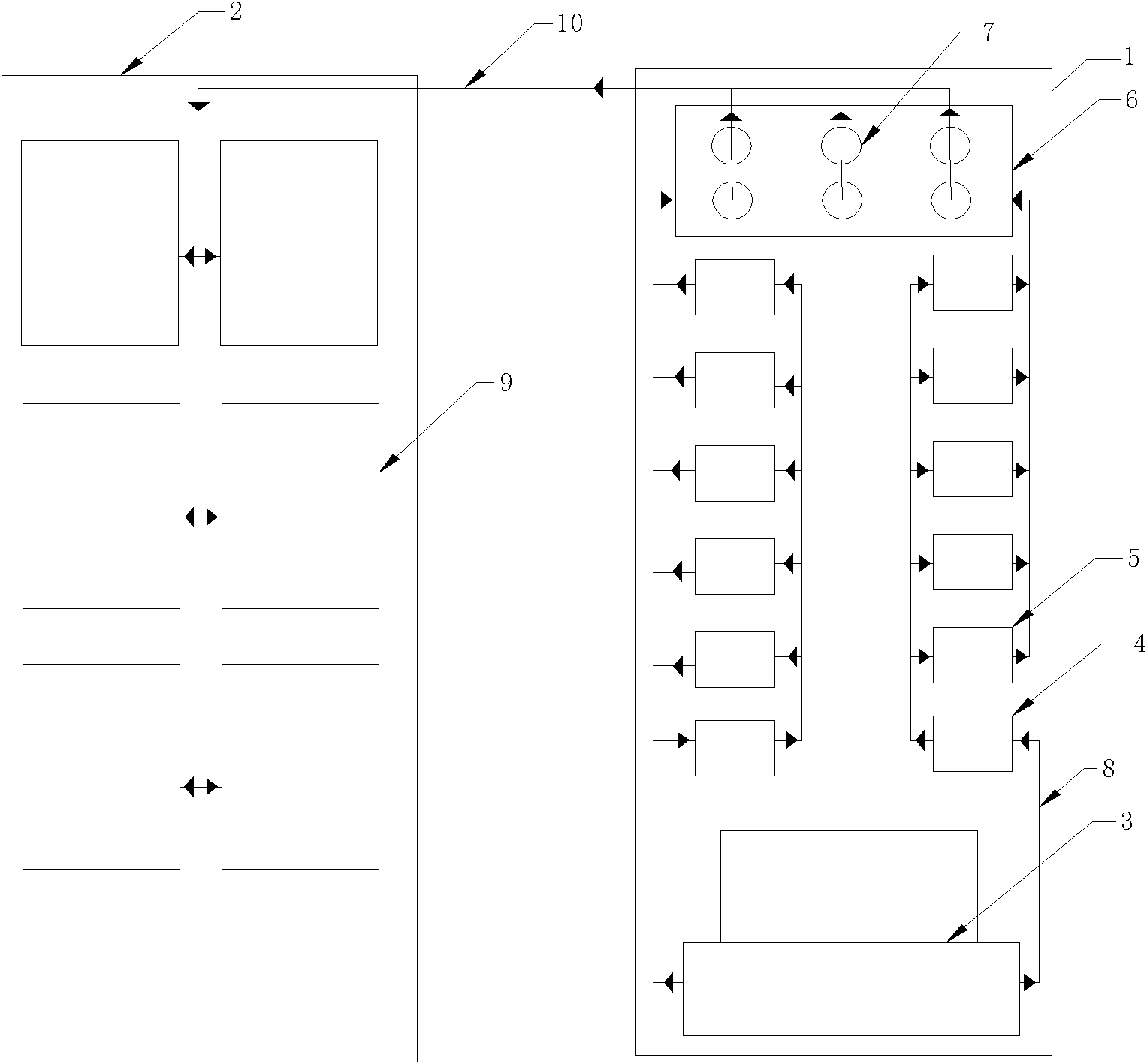

Method used

Image

Examples

Embodiment 1

[0041] 1. DO conditioning board:

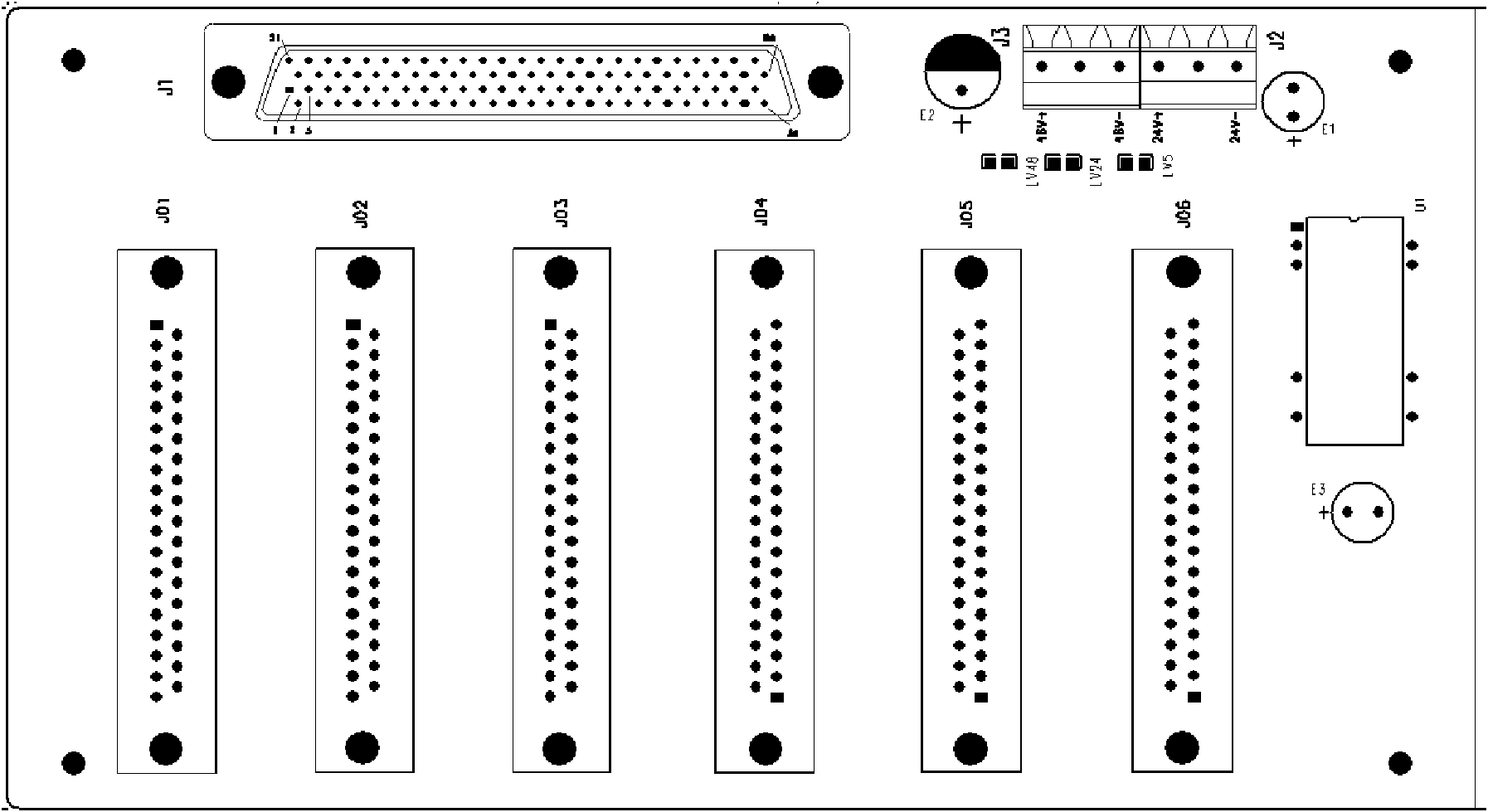

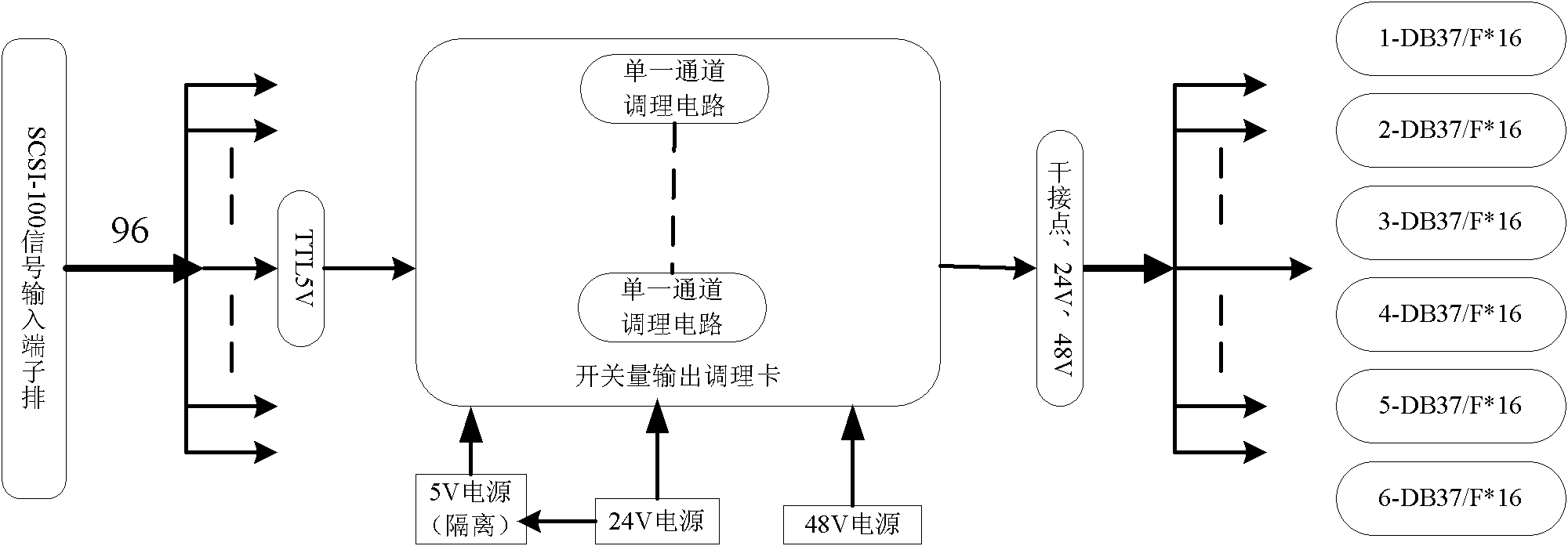

[0042] Such as image 3 As shown, the TTL-5V signals in the 96 channels of the acquisition card signal input terminal block on the industrial computer are introduced into the DO distribution board through the SCSI-100 interface, and are divided into 6 groups on the DO distribution board, each group has 16 channel signals, 6 Group channels are respectively connected to a DO conditioning board. Such as figure 2 As shown, the DO distribution board and the DI distribution board have the same structure. The main function is to introduce the DO signal of the acquisition card into the group and output it to the DO conditioning board, and to collect the signals from the DI conditioning board and output it to the acquisition card. J1 in the figure It is the input interface, J01~J06 is the output interface, J2 is the 24V power supply interface, J3 is the 48V power supply interface, and the DO distribution board is also equipped with a power warning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com