Sensor element with improved air inlet

A technology of sensor elements and air intake holes, which is applied in the direction of instruments, scientific instruments, and material analysis through electromagnetic means, and can solve problems such as increasing diffusion resistance, blocking diffusion barriers, and fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

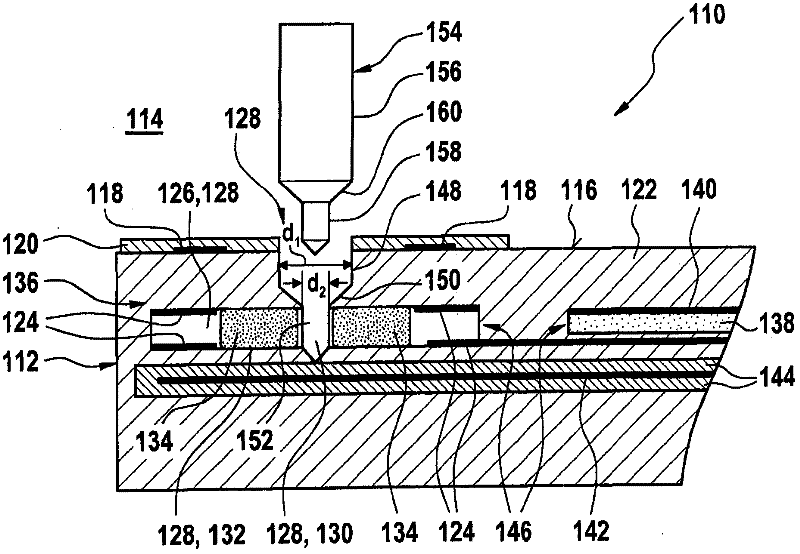

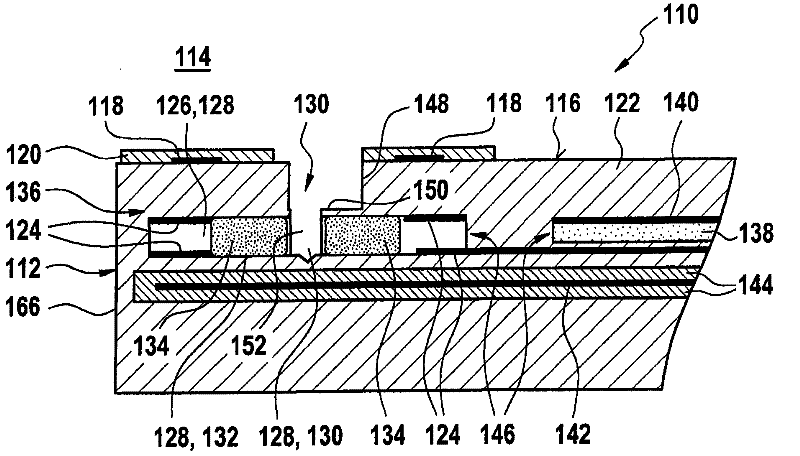

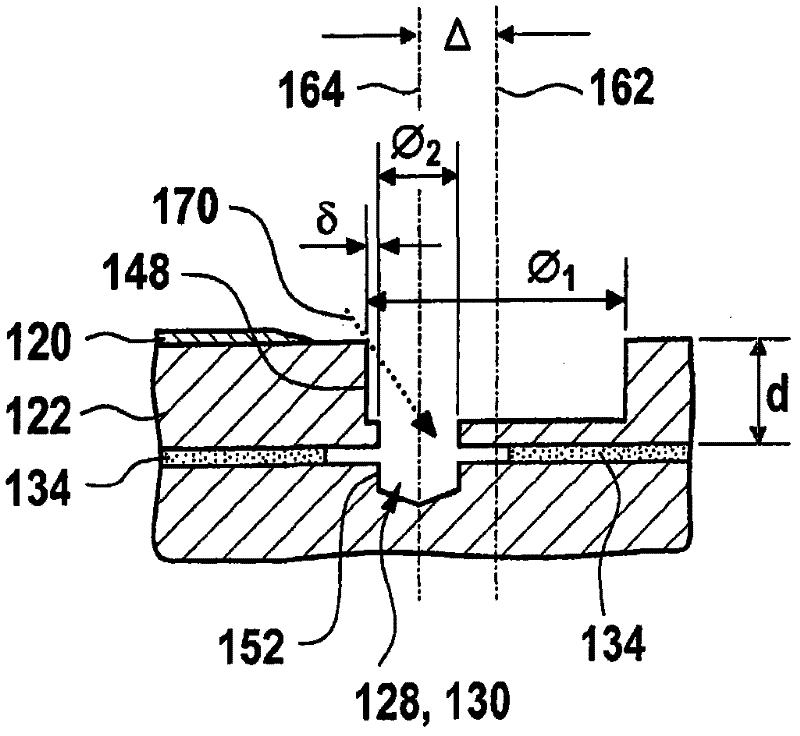

[0032] exist figure 1 A first exemplary embodiment of a sensor element 110 according to the invention is shown in . An exemplary embodiment of the production method according to the invention of such a sensor element 110 should also be explained with the aid of this schematic diagram. The sensor element 110 has a layer structure 112 which can be produced using ceramic thin-film methods and / or thick-film methods. Layer structure 112 includes a surface 116 facing measurement gas chamber 114 , on which surface 116 a first electrode 118 is arranged. exist figure 1 In the exemplary embodiment shown, the first electrode 118 can, for example, be configured as a ring, because figure 1 The sensor element 110 in may mostly have a rotationally symmetrical structure. However, other configurations are also conceivable. First electrode 118 is separated from measurement gas chamber 114 , for example, by a gas-permeable protective layer 120 . Furthermore, layer structure 112 has one or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com