High-temperature high-pressure temperature-reducing pressure-reducing device capable of being started and stopped rapidly

A technology of high temperature and high pressure, temperature reduction and pressure reduction, which is applied in the direction of valve device, valve heating/cooling device, valve fluid energy absorption device, etc. It can solve the problems of poor safety and reliability, slow opening and closing, and large vibration. To achieve the effect of reliable control, good tightness and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

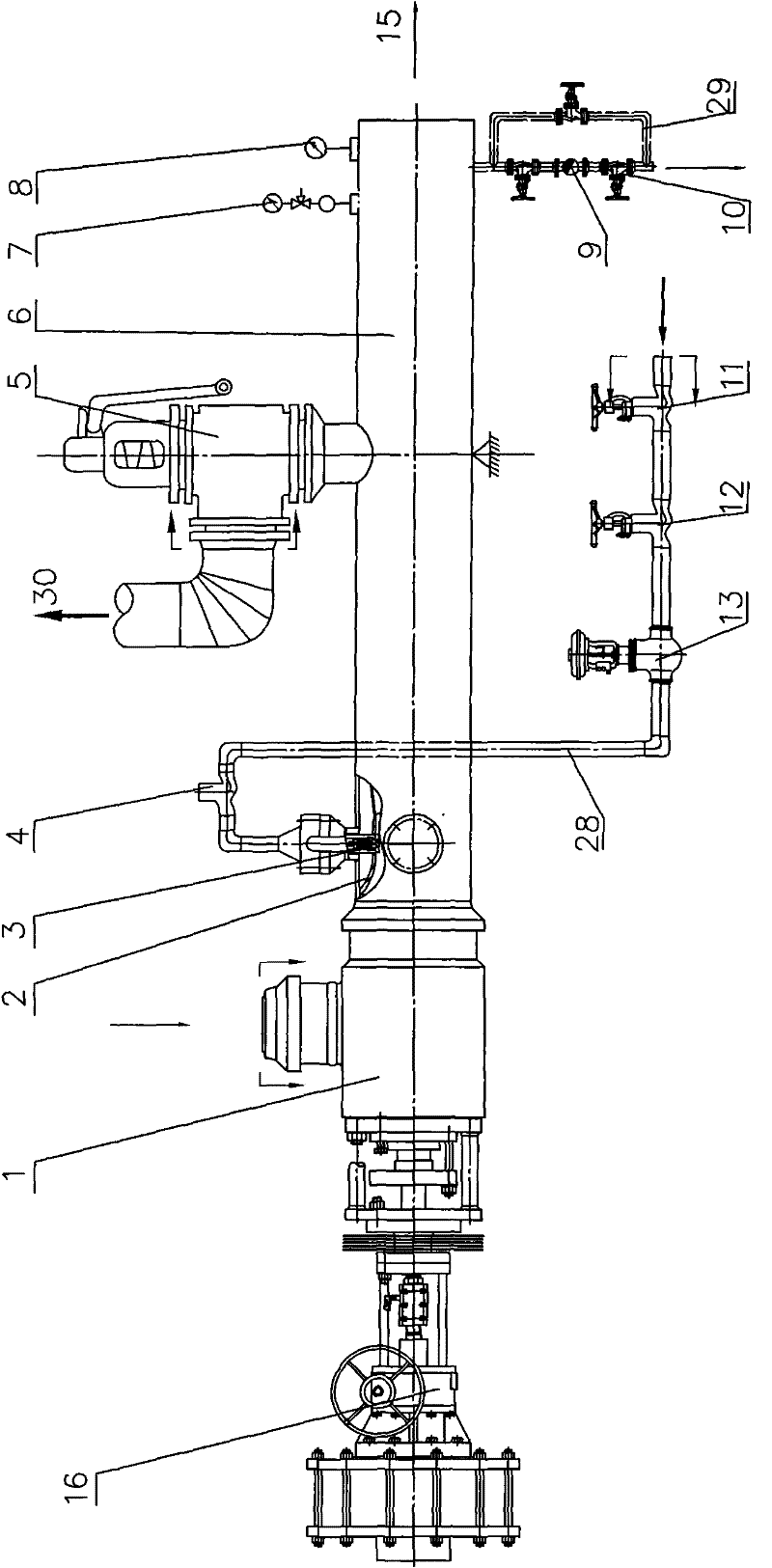

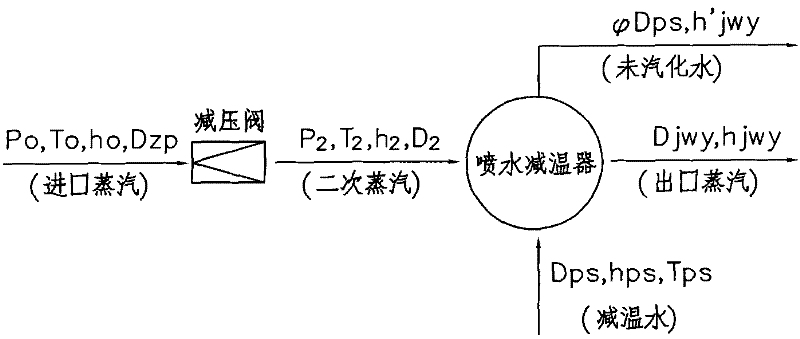

[0018] Example: such as figure 1 , a kind of rapid opening and closing high-temperature, high-pressure, temperature and pressure reduction device, including a pneumatic actuator 16, a steam mixing pipeline 6 connecting a steam inlet 14 and a steam outlet 15, consisting of a valve body 26, a valve core 18, a valve seat 25, and an upper valve cover 24 The pressure reducing valve 1 is formed, wherein the valve core 18 is a valve stem and a valve disc, and the steam mixing pipeline 6 is also provided with a feedwater desuperheating system, a safety protection system and a drainage system.

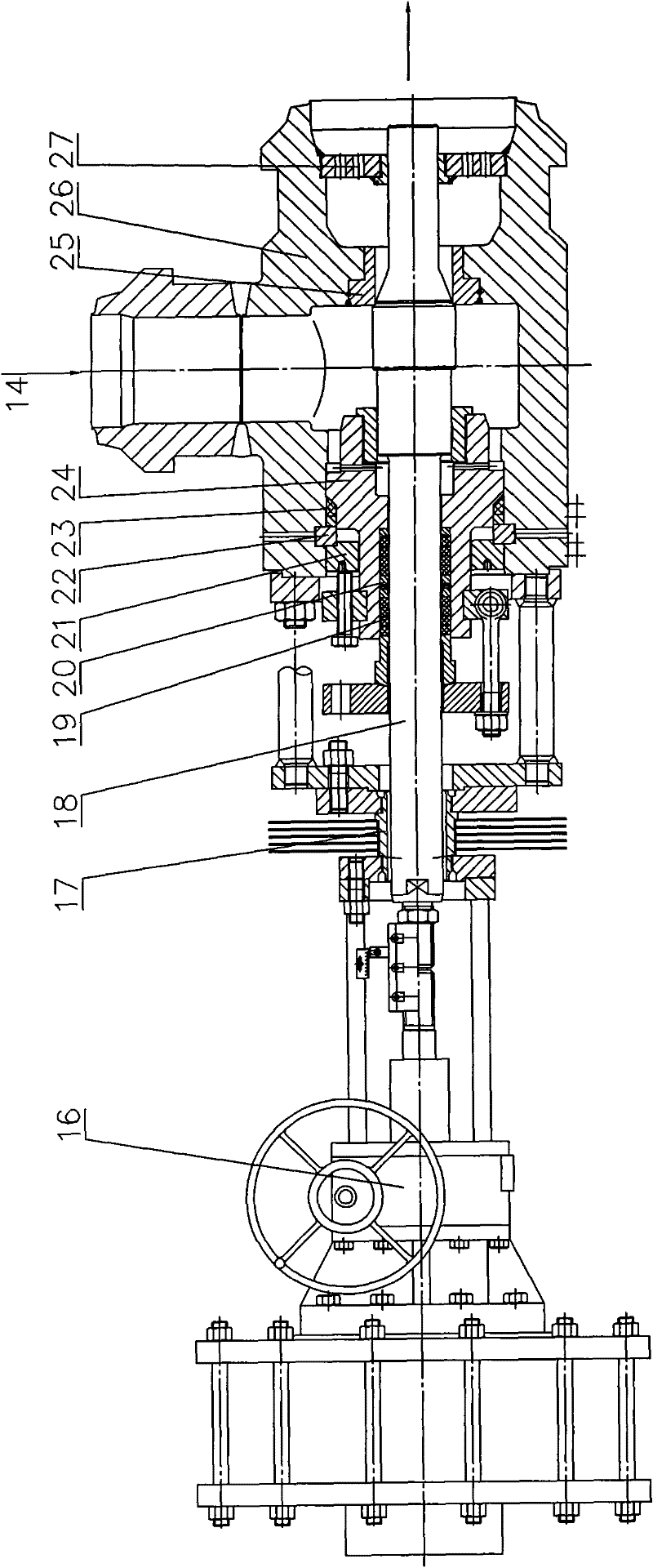

[0019] Such as figure 2 , wherein the end of pressure reducing valve 1 is provided with porous sound-absorbing cover 27, and between upper valve cover 24 and valve body 26, asbestos thermal ring 23, four-open ring 22 and retaining ring 21 are respectively provided. A sealing packing 19 and a packing spacer 20 are arranged between the upper valve cover 24 and the valve core 18 . A cooling fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com