Efficient mining method for thick metal ore body in slanting

A mining method and thick metal technology, applied in ground mining, underground mining, special mining, etc., can solve problems such as difficulty in mining upper mineral resources, inability to by-produce ore, and multiple footwall rocks, so as to solve ore dilution and prevent Surrounding rock caving on the hanging wall, reducing the effect of ore loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

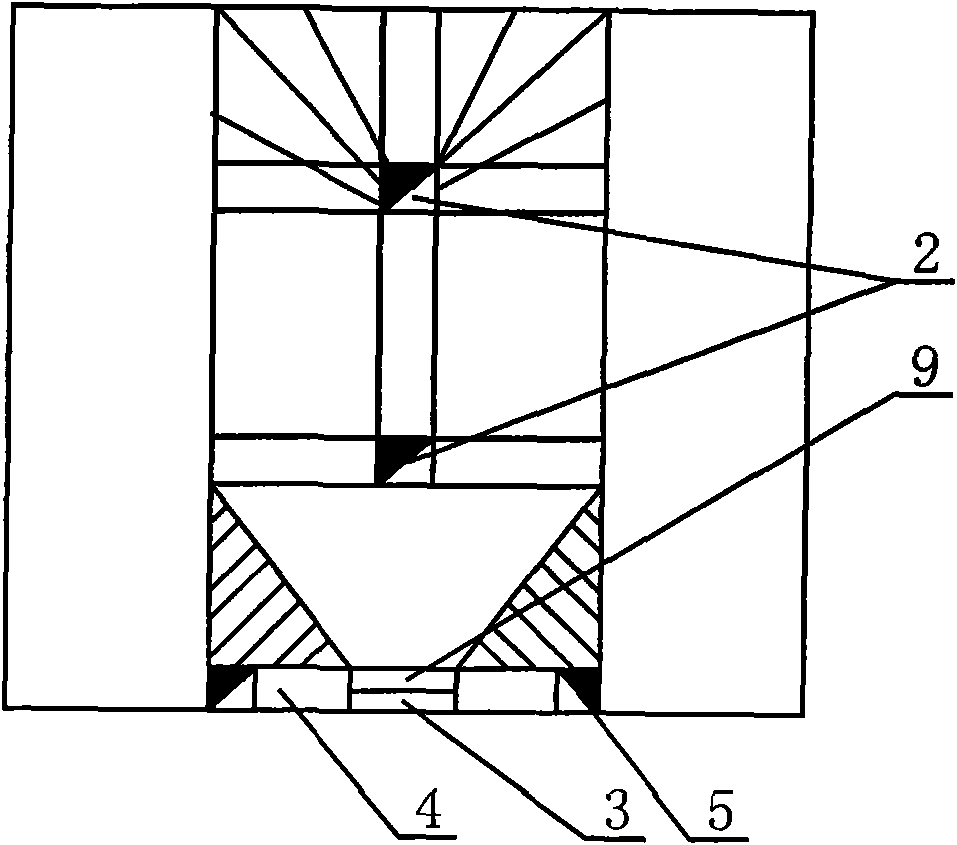

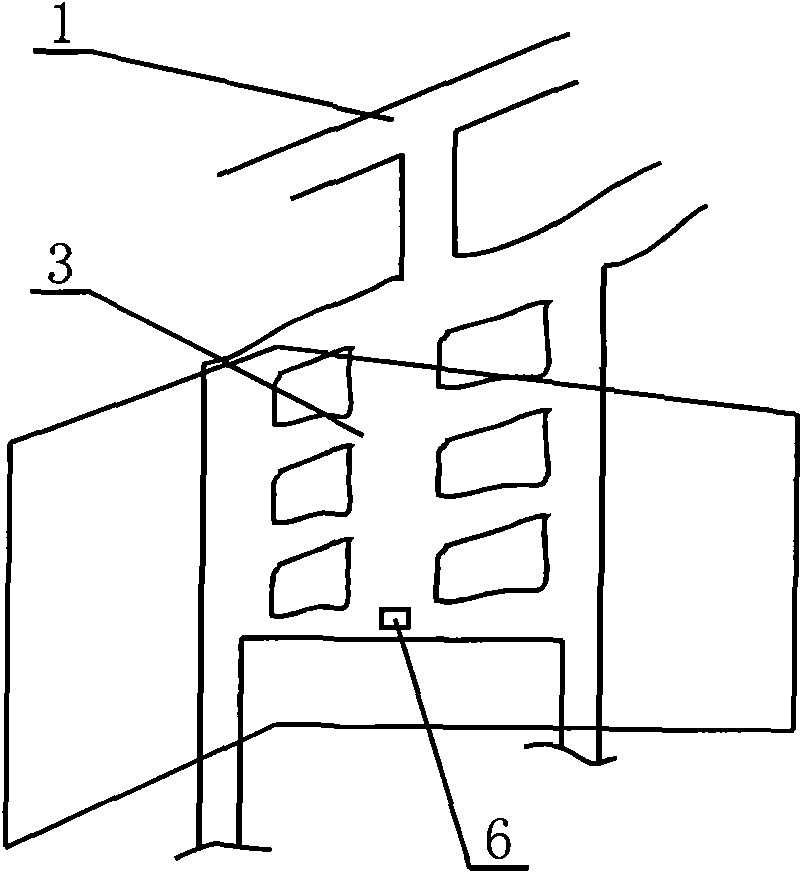

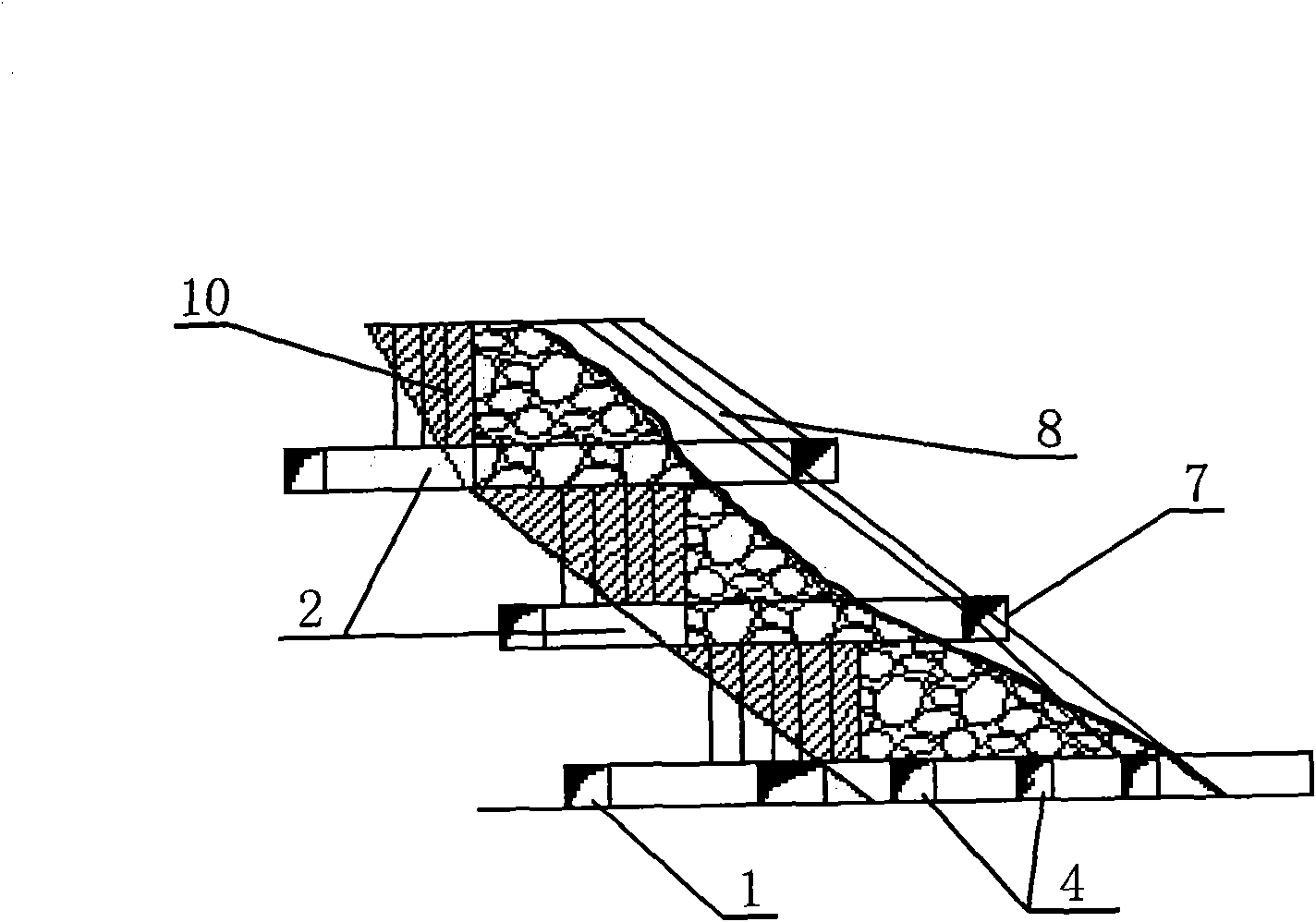

[0028] Below in conjunction with accompanying drawing and example further illustrate the present invention.

[0029] (1) Experimental site and geological situation of the experimental ore block

[0030] The 171# vein of Linglong Gold Mine of Shandong Gold Group has a dip angle of 40-45°, a maximum horizontal thickness of 22.5m, an average ore body thickness of 13.8m, and an average grade of 1.50g / t. The ores are pyrite-sericite and pyrite-sericite cataclast rock, the surrounding rocks are generally stable, the rocks in the fractured alteration zone at the boundary of the ore body hanging wall are relatively broken, and there is an aquifer in the hanging wall surrounding rock. Because this mining area does not possess the filling conditions, in order to recover the 171# ore lode safely and efficiently as soon as possible to meet the production needs, it is decided to adopt the non-filling mining method of the present invention.

[0031] The test stope is selected between the 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com