Superhigh-strength armour plate and manufacturing process thereof

An ultra-high-strength, manufacturing process technology, applied in the field of ultra-high-strength lightweight steel plates and their manufacturing and forming processes, can solve the problems of high alloy content and the inability to meet the requirements of lightweight and high ballistic resistance and high cost performance of bulletproof steel plates at the same time. , to achieve the effect of good flatness

Active Publication Date: 2011-09-14

东莞市豪斯特热冲压技术有限公司

View PDF4 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Although the above representative typical products have their own characteristics, they have high alloy content and cannot meet the requirements of light weight, high bulletproof performance and high cost performance of bulletproof steel plates at the same time.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

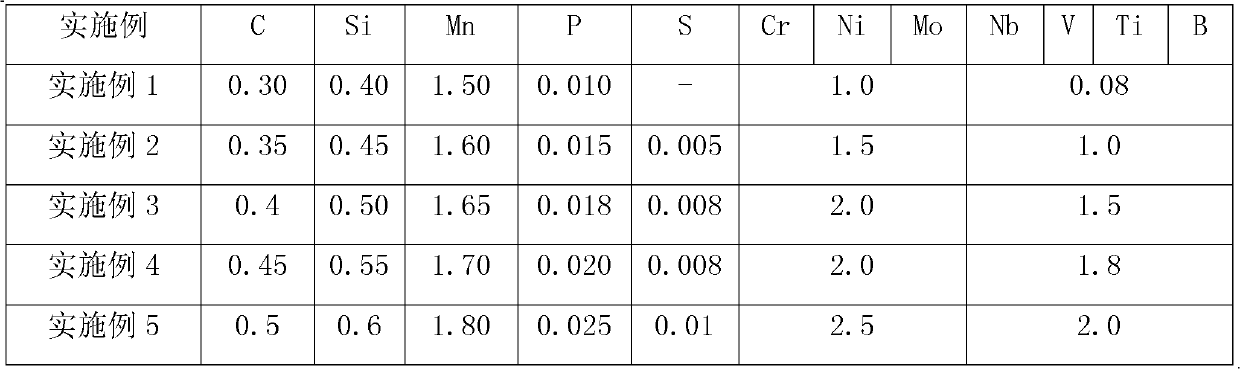

[0015] Table 1 is the chemical composition of the ultra-high-strength bulletproof steel plate of the present invention;

[0016] Table 1B Chemical composition of high-strength bulletproof steel plate

[0017]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

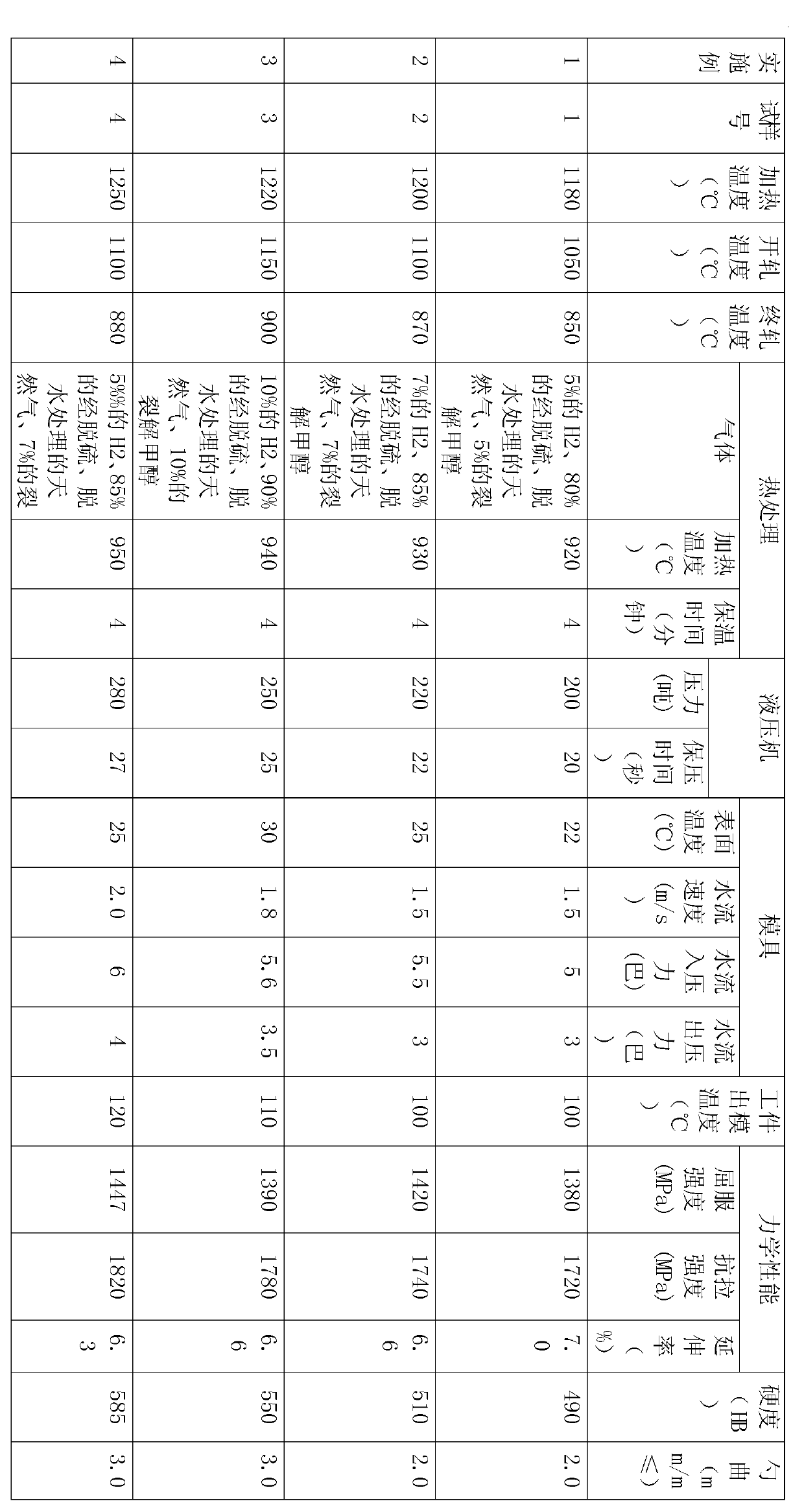

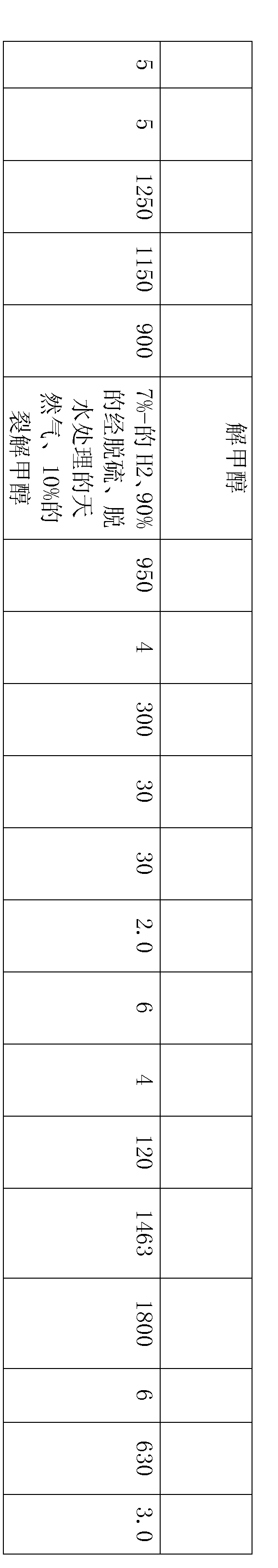

The invention discloses a superhigh-strength armour plate and a manufacturing process thereof. The superhigh-strength armour plate comprises the following chemical components in percentage by weight: 0.30- 0.5% of C, 0.40-0.60% of Si, 1.50-1.80% of Mn, not more than 0.025% of P, not more than 0.01% of S, not more than 2.5% of the sum of Cr, Ni and Mo, not more than 0.20% of the sum of Nb, V, Ti and B and the balance of Fe. Based on a low alloy component design, the manufacturing process of the superhigh-strength armour plate comprises the following steps of: heating at 1180-1250 DEG C, performing primary rolling at 100-1150 DEG C, performing final rolling at 850-900 DEG C and performing thermal treatment at 900-950 DEG C; in addition, a water-cooling hot impact forming process is also adopted in the manufacturing process, wherein water flows into a die at the pressure of 7-8bar, exit pressure is 5.5-7bar, water velocity is 1.5-3m / s. By using the manufacturing process, a 2.2mm-thickness B-grade superhigh-strength light armour plate and a 3.7mm-thickness C-grade superhigh-strength light armour plate which meet all performance requirements and have good plate flatness and no oxide skin on the surface can be manufactured.

Description

technical field [0001] The invention relates to an ultra-high-strength lightweight steel plate and its manufacturing and forming process, in particular to a thermoforming manufacturing process of a bullet-proof bullet-proof steel plate for an explosion-proof vehicle. Background technique [0002] In the face of various contradictions and complicated public security situation, all countries are strengthening the anti-terrorism and anti-explosion public security work, and the demand for anti-terrorism and anti-explosion vehicles is increasing day by day. Anti-terrorism and explosion-proof vehicles require not only high bulletproof performance, but also good mobility and energy saving and emission reduction performance. Thinning the thickness of bulletproof steel plates and making bulletproof vehicles lightweight is one of the effective ways to improve vehicle mobility and achieve the purpose of energy saving and emission reduction. However, while reducing the thickness of the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/54C22C38/32C22C38/14C22C38/12C21D8/02C21D1/18

Inventor 马鸣图黄镇如马豫昊孙智富赵国刚

Owner 东莞市豪斯特热冲压技术有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com