Novel preparation method of rubber-clay nanocomposite

A nano-composite material and rubber technology, which is applied in the new preparation field of rubber and clay nano-composite materials, can solve problems such as poor strengthening ability, and achieve the effects of protecting the environment, simplifying the processing technology, improving the microscopic phase structure and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

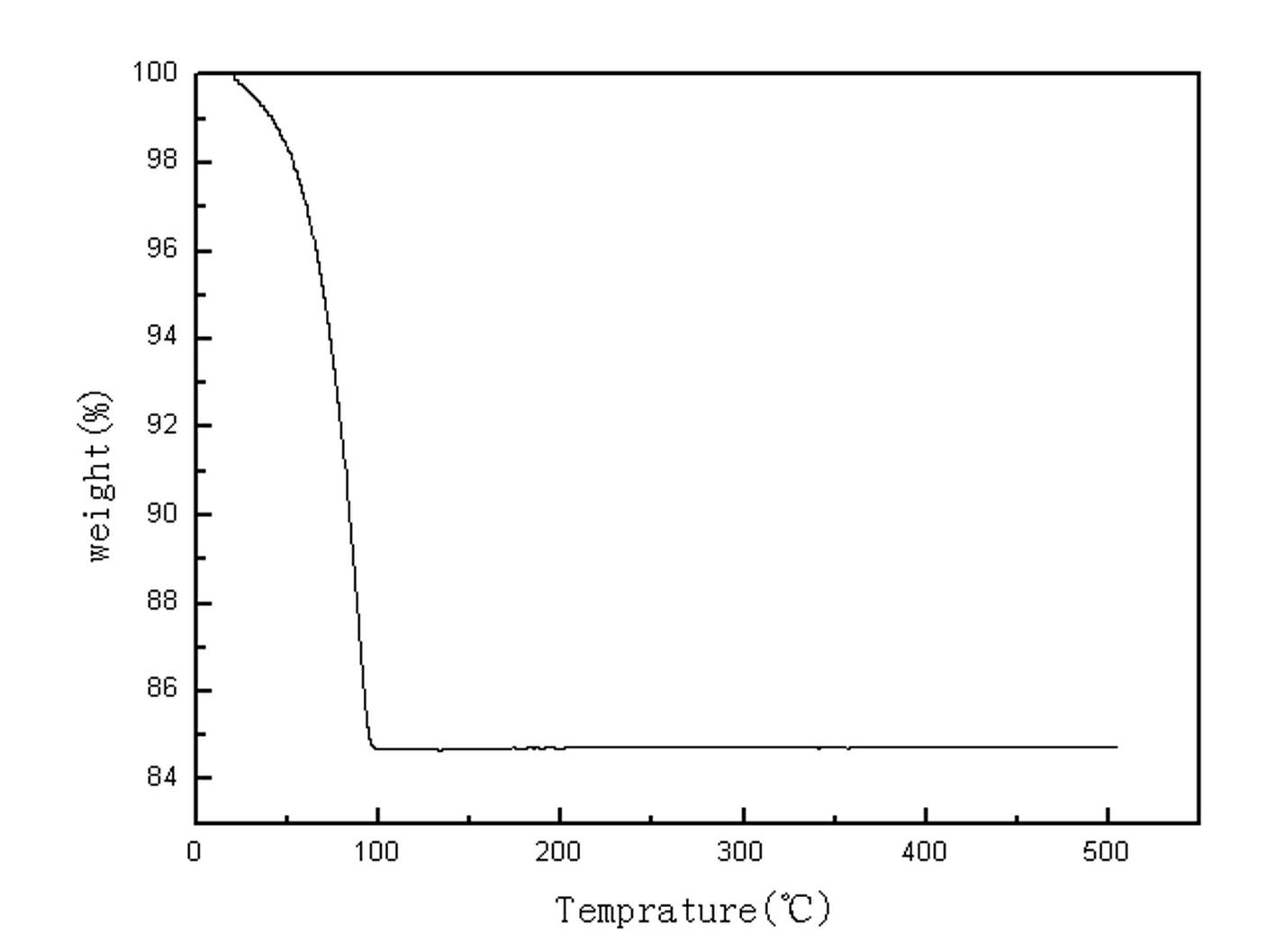

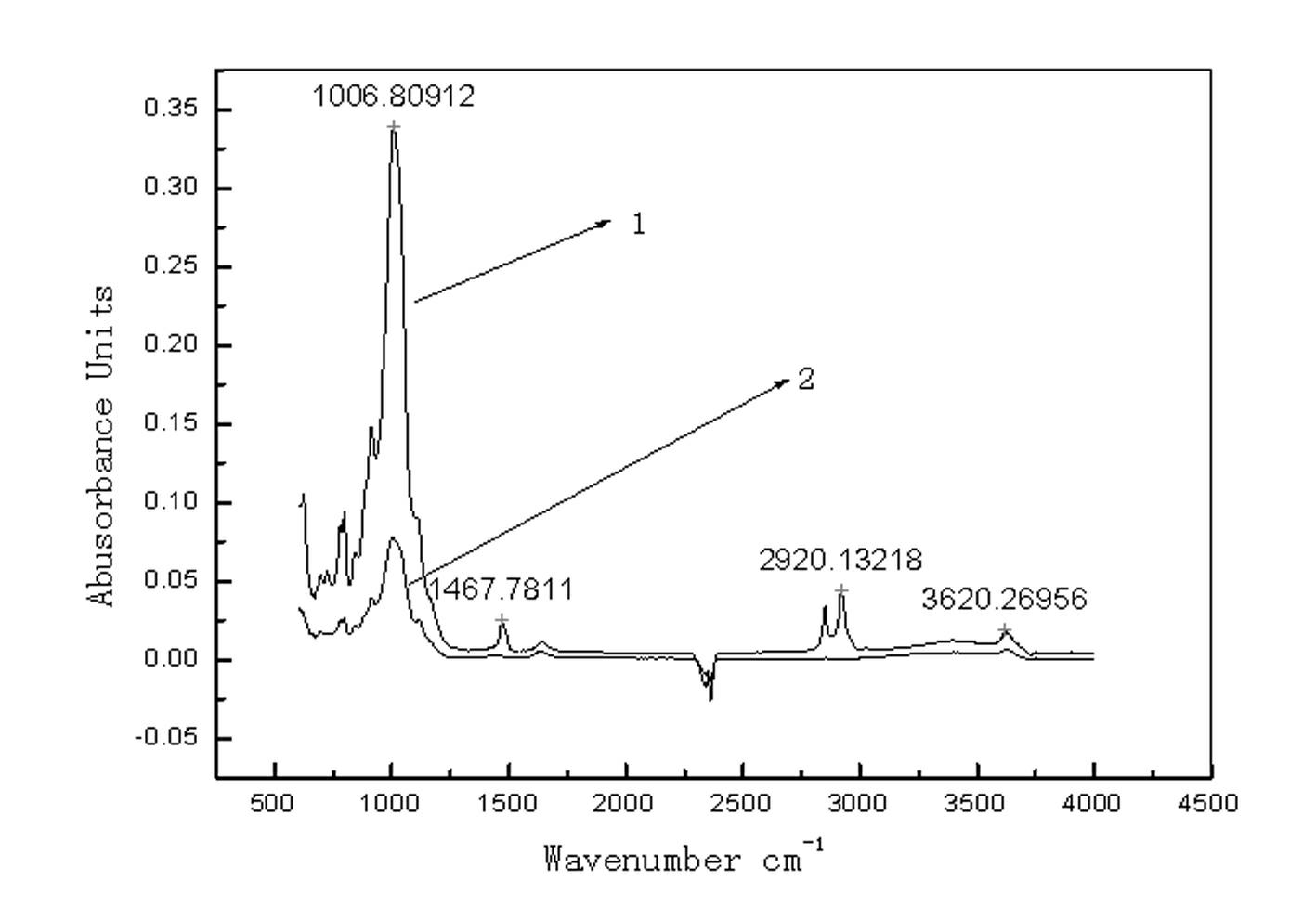

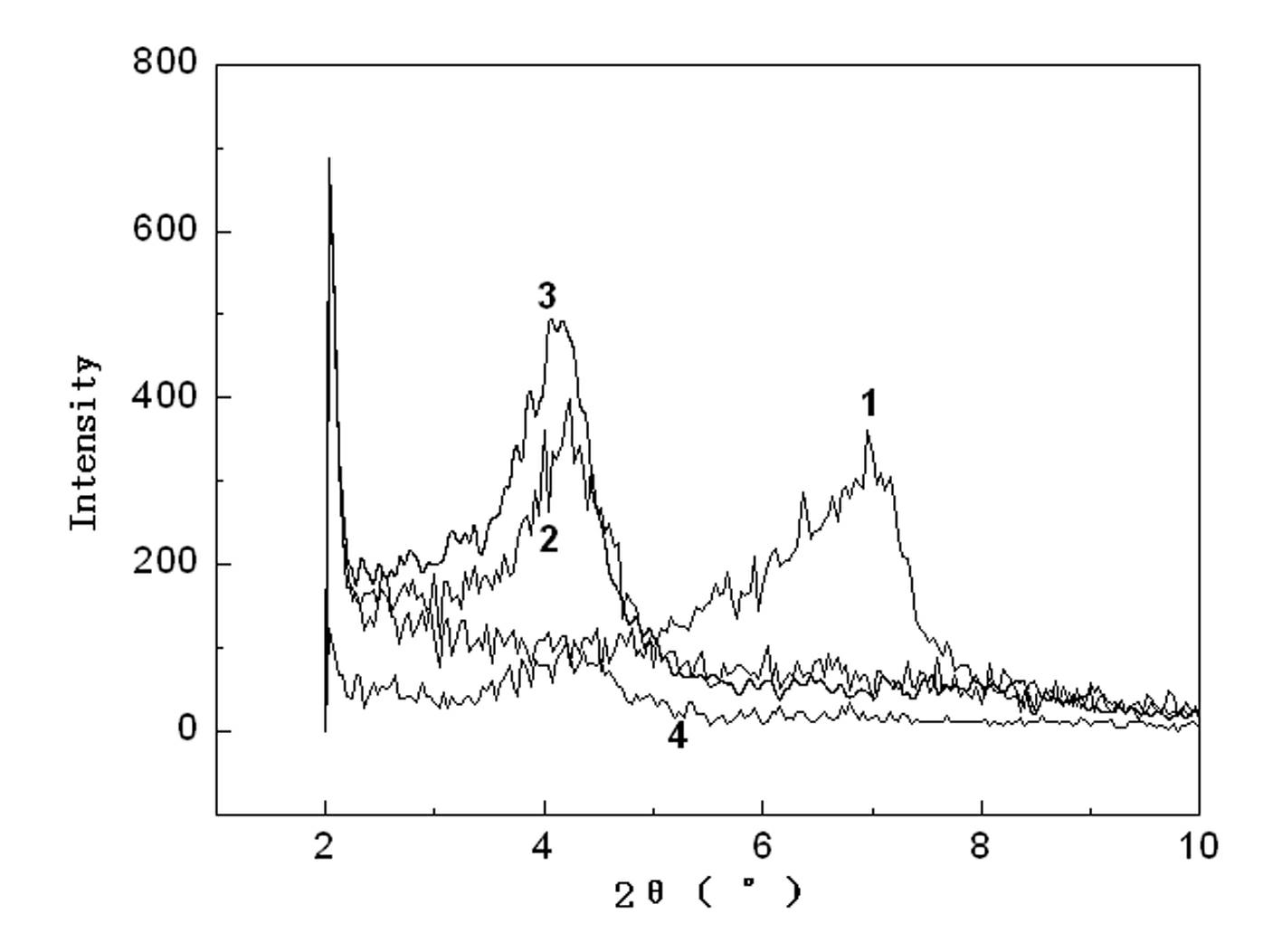

Method used

Image

Examples

Embodiment 1

[0058]Prepare mud liquid according to the ratio of inorganic clay and deionized water as 1g:10ml, raise the temperature to 65°C in a water bath, and adjust the mud liquid to PH=7, according to the quality of cetyltrimethylammonium bromide and the quality of inorganic clay Cetyltrimethylammonium bromide is configured into a solution at a ratio of 1:3, and is added dropwise to the mud liquid under strong stirring, and n-butanol is added at the same time according to the ratio of inorganic clay: n-butanol = 1g: 1ml, Stir at a constant temperature of 65°C for 12h. After the solution was cooled to room temperature, suction filtration was performed, and 0.1mol / L AgNO 3 The solution is titrated to the filtrate until there is no bromide ion in the filtrate, and the pre-expanded organoclay is obtained by drying at room temperature, which is ground and set aside. Mix 100 parts of nitrile rubber and 5 parts of pre-expanded organic clay on a double-roller mill for about 30 minutes, then ...

Embodiment 2

[0060] The nitrile rubber is changed into brominated butyl rubber, and all the other operation steps are with embodiment 1, adopt the scanning electron microscope photograph of the organoclay and brominated butyl rubber nanocomposite material prepared by the preparation technology of the present invention as Figure 7 The mechanical properties are shown in Table 2.

Embodiment 3

[0062] Change n-butanol to acrylic acid, and the rest of the operation steps are the same as in Example 1. The mechanical properties of the organoclay and nitrile rubber nanocomposite prepared by the preparation technology of the present invention are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com