Method for removing water from ethyl acetate and butanone mixed solvent

A technology of ethyl acetate and mixed solvent, applied in the field of precise water removal, can solve the problems of easy agglomeration of sodium sulfate, poor economic effect, unsuitable for water removal, etc., and achieves simple post-treatment process, good treatment effect, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

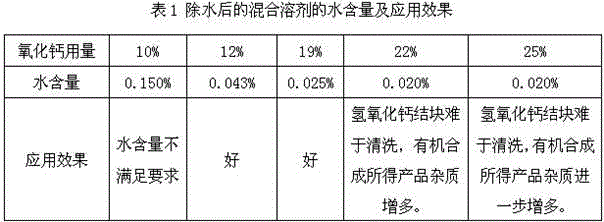

[0019] Take the mixture of ethyl acetate and methyl ethyl ketone, the water content in the mixture is between 2.5-3.2%, then add the mixture and calcium oxide into the distillation kettle at the same time, the amount of calcium oxide is respectively 10%, 12%, and 19%, 22%, 25%. After the addition, heat the still to 75-80°C, and heat to reflux at this temperature for 2-4 hours. After the reflux, continue to distill the mixed solution in the still, and recover ethyl acetate with a water content that meets the requirements through the condenser. The mixed solvent of ester and butanone, the water content in the mixed solvent is shown in Table 1 below.

[0020]

[0021] It can be seen from the above table that when the water content is below 4%, the dosage of calcium oxide in the range of 12-19% is more appropriate, and the removal effect of water in the mixed solvent is the best, which can not only meet the water content requirements, but also affect the later stage. There is ...

Embodiment 2

[0023] Take the mixture of ethyl acetate and methyl ethyl ketone, and detect that the moisture content in the mixture is 4-4.5%, then add the mixture and calcium oxide to the distillation kettle at the same time, and the consumption of calcium oxide is 15%, 19%, and 25%, 27%, 30%. After the addition, heat the still to 75-80°C, and heat to reflux at this temperature for 2-4 hours. After the reflux, continue to distill the mixed solution in the still, and recover ethyl acetate with a water content that meets the requirements through the condenser. The mixed solvent of ester and butanone, the water content in the mixed solvent is shown in Table 2 below.

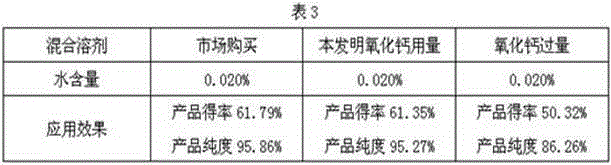

[0024]

Embodiment 3

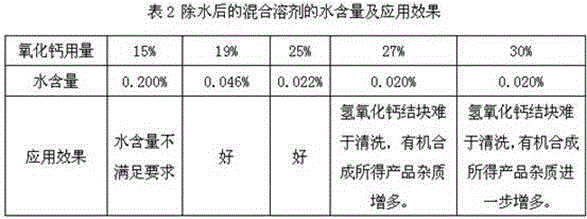

[0026] It is detected that the moisture content in the mixture obtained by distillation is 3.2%, and then the mixture and calcium oxide are added to the distillation kettle simultaneously, and the consumption of calcium oxide is 15.6% of the mixture quality. After the addition, heat the still to 75-80°C, and heat to reflux at this temperature for 2-3 hours. After the reflux, the moisture content in the still is detected to be 0.021%. After the reflux, pour out the mixed solution in the still. The generated calcium hydroxide is removed by centrifugation to obtain a mixed solvent of ethyl acetate and butanone with a water content meeting the requirements. The distillation pot from which the mixed solution is poured out can be cleaned with deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com