Stripper for pipe with diameter of 300-4000 mm

A demoulding machine and pipe technology, which is applied in the field of demoulding machine manufacturing, can solve the problems of low demoulding efficiency, inconvenient operation, labor-intensive, etc., and achieve the effect of high production efficiency, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

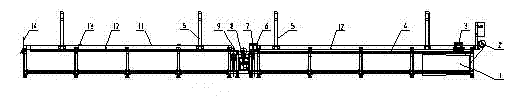

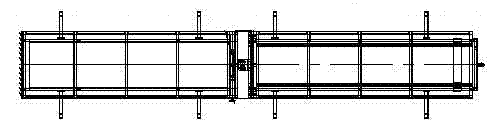

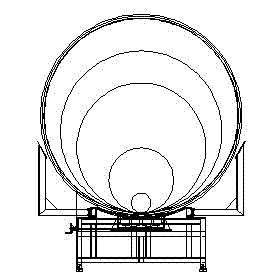

[0010] Embodiment 1: with reference to attached Figure 1-3 . A demoulding machine for pipes with a diameter of 300-4000mm, which is characterized in that it is composed of a receiving mold assembly and a demoulding table assembly. The front end of the receiving mold assembly has a baffle plate 9 to limit the position, an arc-shaped support plate 11 in the middle, and a limit block 14 at the rear end. , the accepting mold is located on the mold support 13, the long crosspiece 12 is fixed on the mold support 13, the protective frame 5 is vertically fixed on the long crosspiece 12, the demoulding support 7 of the demoulding table assembly is provided with a track 4, and a trolley 3 Located on the track 4, one end of the frame is provided with a hoist 1 and the steel wire rope in the hoist 1 passes the fixed pulley 2 at the end of the frame to pull the trolley 3, the long crosspiece 12 is fixed on the demoulding frame 7, and the protective frame 5 is vertically fixed on the On t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com