Continuous high-temperature sterilization dehydration equipment

A dehydration equipment, high temperature sterilization technology, applied in lighting and heating equipment, waste disinfection or sterilization methods, drying and other directions, can solve the problem of the temperature that cannot kill bacteria, the trouble of garbage feeding and discharging, and the continuous high temperature. stability and other issues to achieve the effect of facilitating process processing, improving efficiency and removing moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

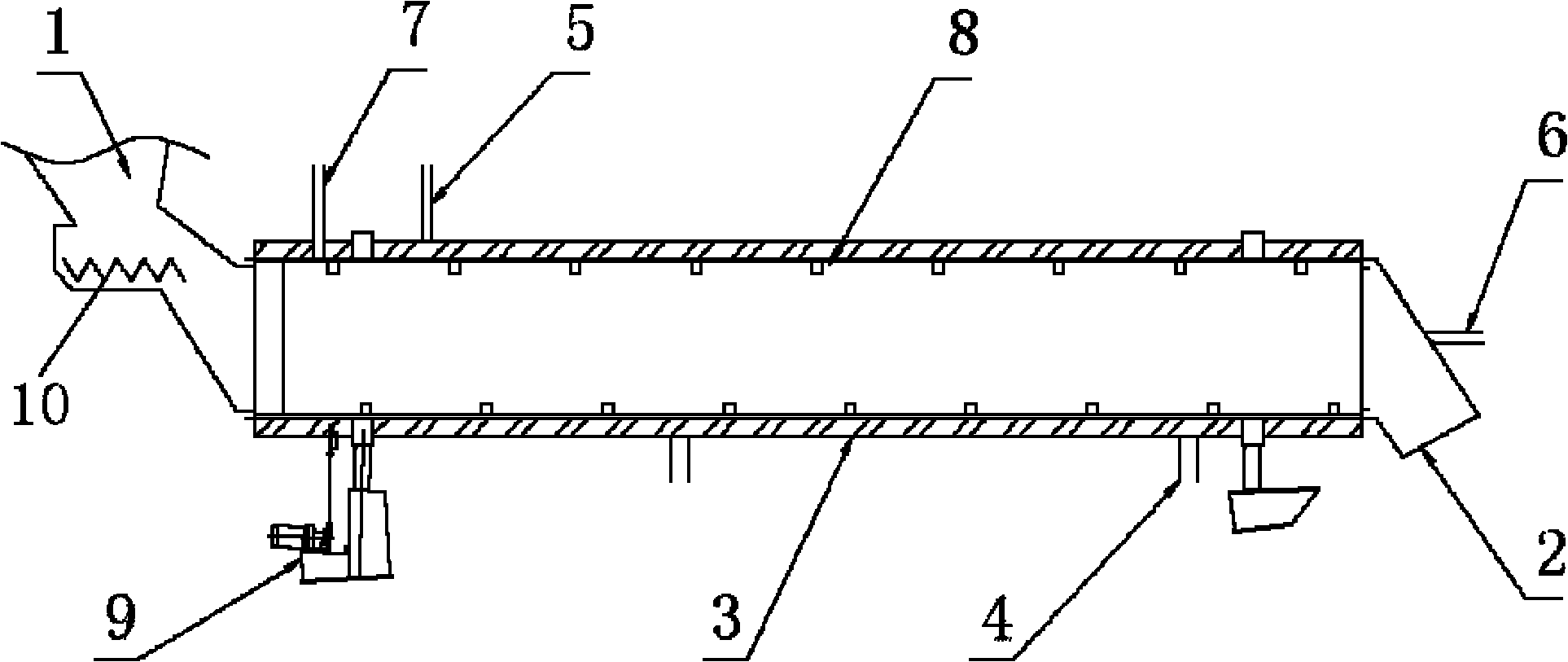

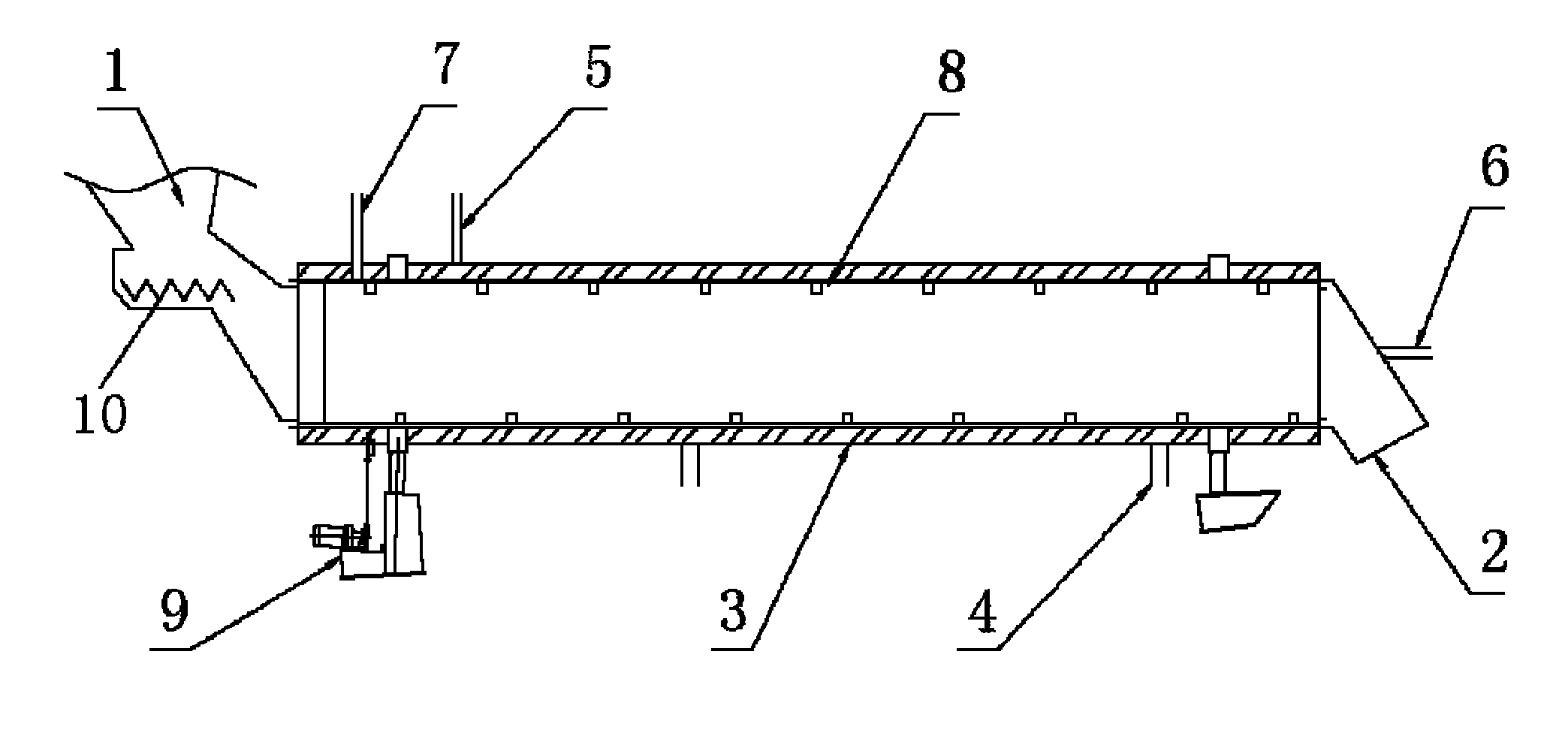

[0013] A continuous high-temperature sterilization and dehydration equipment, including a horizontally installed rotary drum that can place materials, the axis of the rotary drum forms an angle of 2 to 16° with the horizontal line, one end of the rotary drum is the feed port 1, and the other end is the The discharge port 2, the feed port 1 end is higher than the discharge port 2 end.

[0014] An interlayer 3 is provided on the outer cylinder wall of the rotary drum, and a hot air inlet 4 and a hot air outlet 5 are arranged on the interlayer 3. The hot air inlet 4 and the hot air outlet 5 are arranged at both ends of the rotary drum, and at the discharge port 2 A steam inlet 6 is also provided at the center, and a steam outlet 7 is provided on the rotary drum near the feed port 1 of the rotary drum.

[0015] The equipment heats the garbage through the hot air in the interlayer 3 of the cylinder wall, and the high-temperature steam entering the tail of the cylinder directly ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com