Drug-mixing connector for plastic infusion soft bag

A technology for infusion soft bag and drug mixing, which is applied to the field of drug mixing interface and drug mixing interface of plastic infusion soft bag, can solve the problems of over-welding of soft bag, waste of raw materials, contamination of liquid medicine, etc. Mechanical properties, combined with smooth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

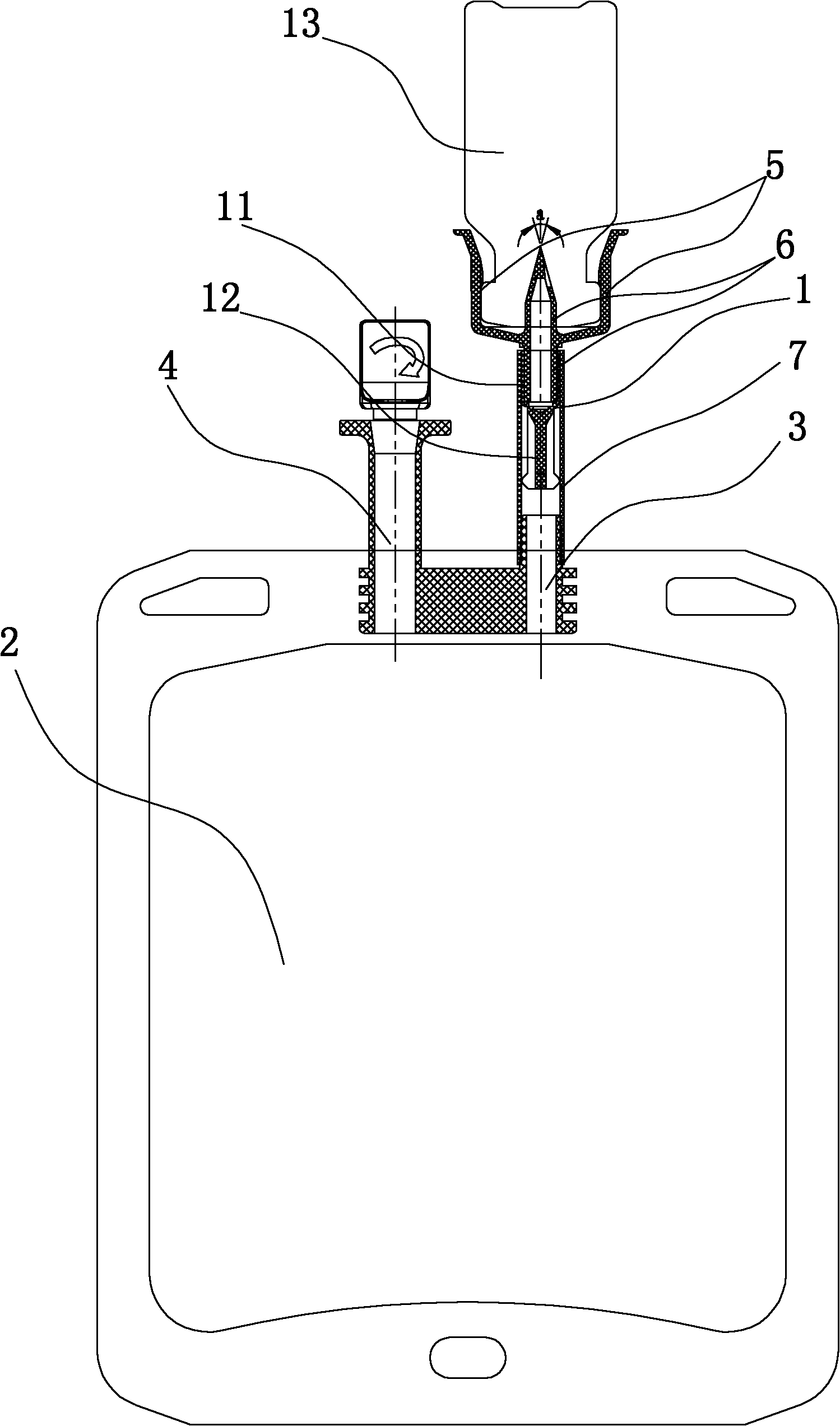

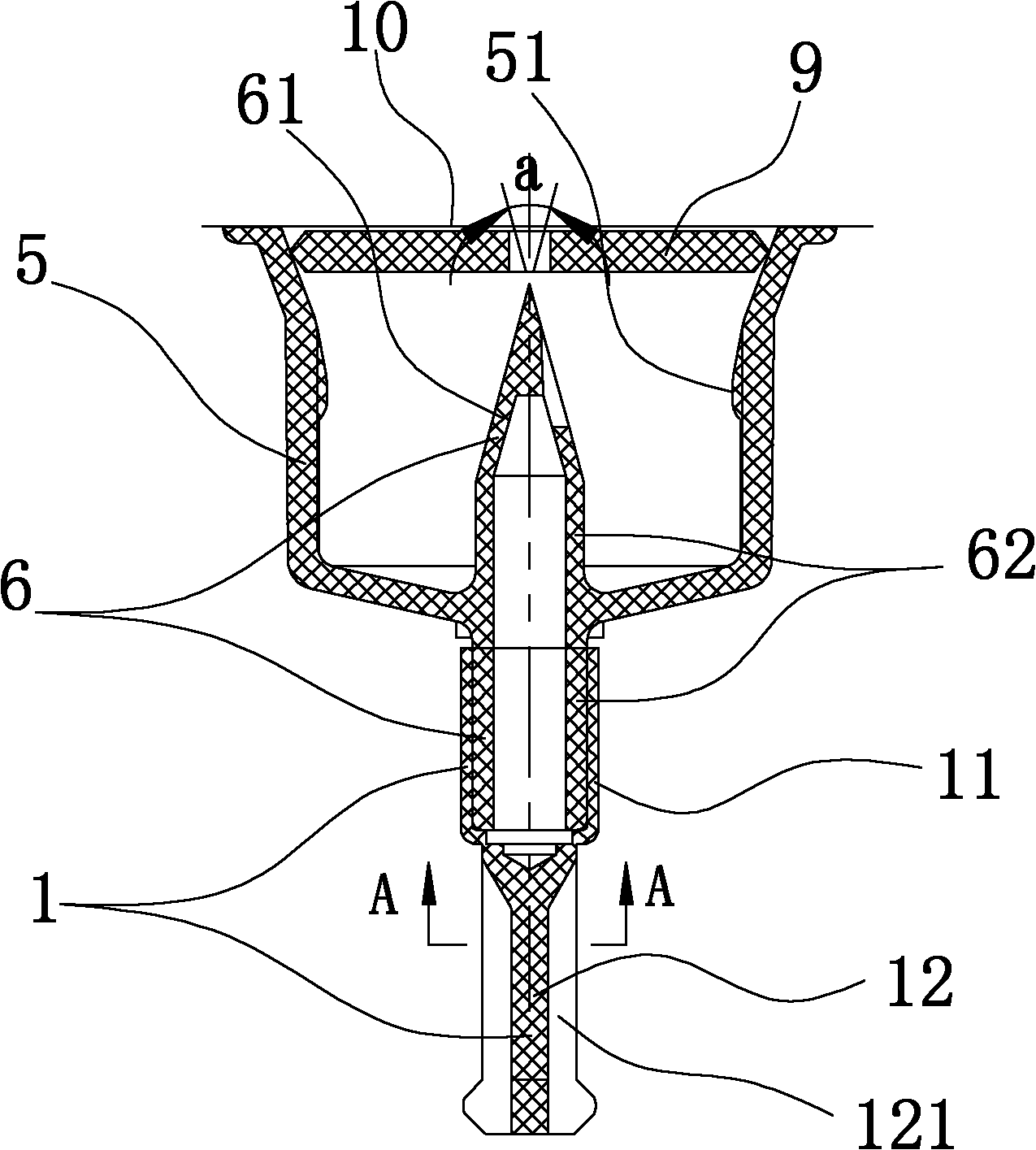

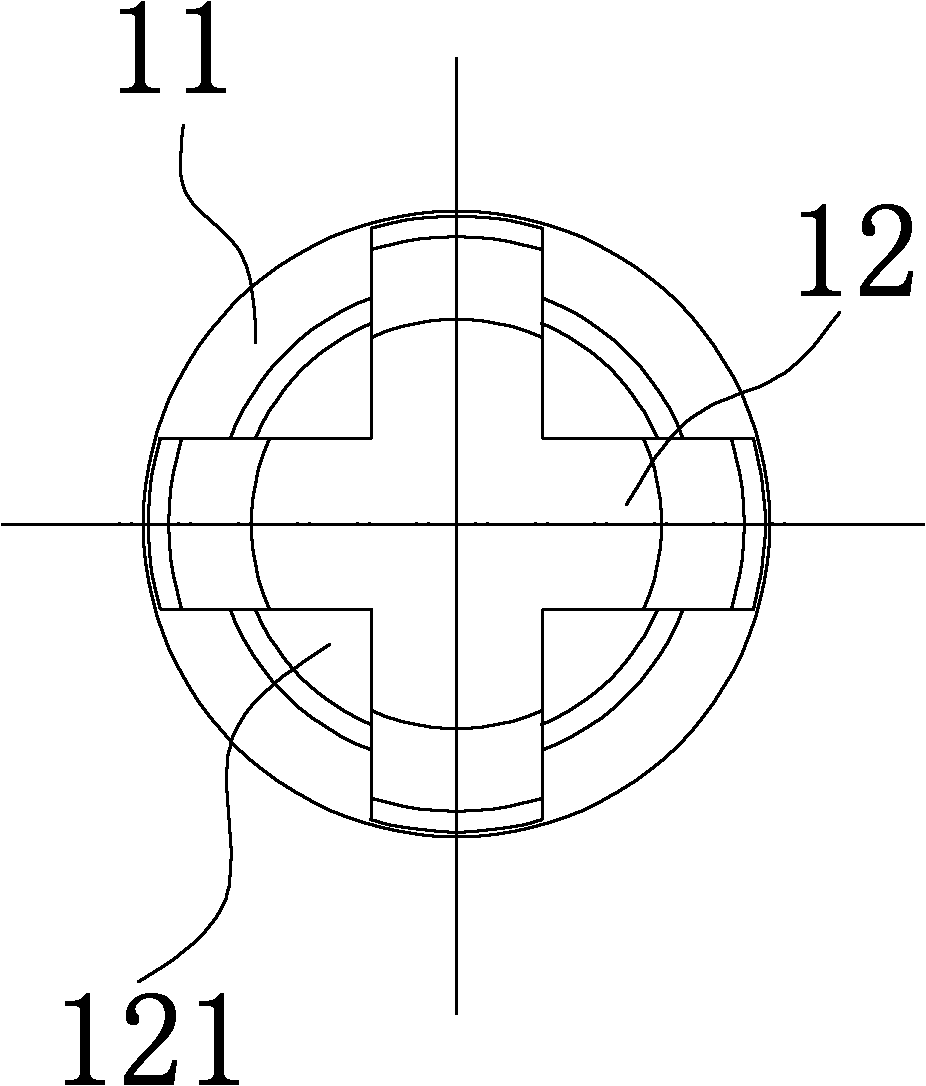

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 Shown is a plastic infusion bag provided by the present invention that will not damage the soft infusion bag when the frangible handle is broken during the drug mixing process, and the handle section of the frangible handle will not fall into the soft infusion bag after being broken. The drug mixing interface of the infusion soft bag. The drug mixing interface includes an easy-to-break handle 1, a soft infusion bag 2, and a hard double interface connected to the soft infusion bag 2 containing a drug mixing channel 3 and an infusion channel 4; the drug mixing channel 3 is connected to a drug mixing card body 5 and the mixing nozzle of the syringe body 6 also includes a sealing rubber tube 7, the mixing nozzle is connected to the mixing channel 3 through the syringe body 6 and the sealing rubber tube 7, and the easy-folding handle 1 is sleeved on the syringe in the sealing rubber tube 7 body 6 e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com