Steam exhaust diffusion flow guiding structure of steam turbine and steam turbine

A steam turbine and steam exhaust technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the risk of increasing steam leakage, complicated installation and maintenance of low-pressure outer cylinders, and the inability of the upper half of low-pressure outer cylinders to fall into place as a whole and other problems to achieve the effect of avoiding the decline of aerodynamic performance, improving aerodynamic performance, and good aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical features and effects of the present invention in detail, and can be implemented in accordance with the content of this specification, the following further describes the embodiments of the present invention in conjunction with the accompanying drawings.

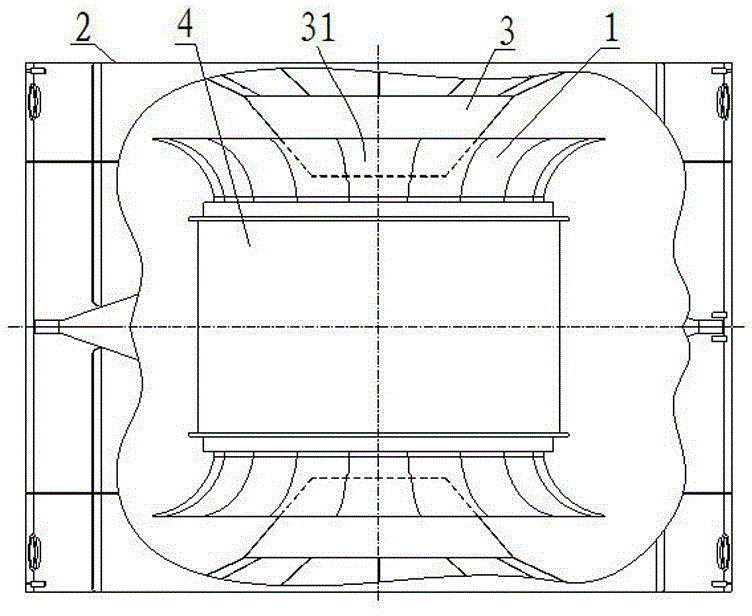

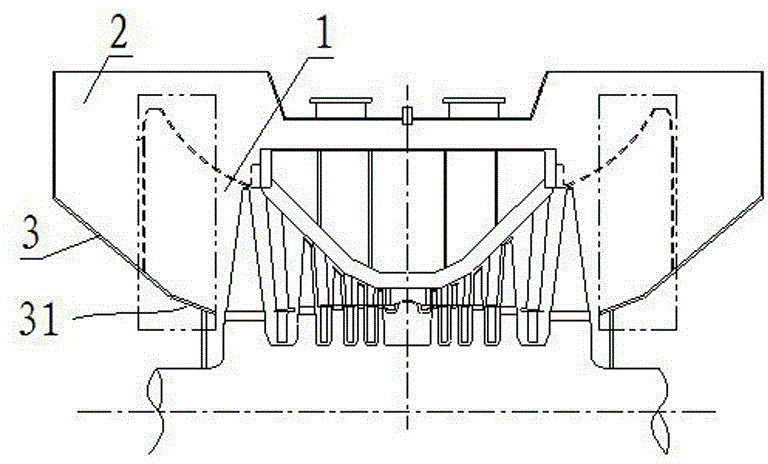

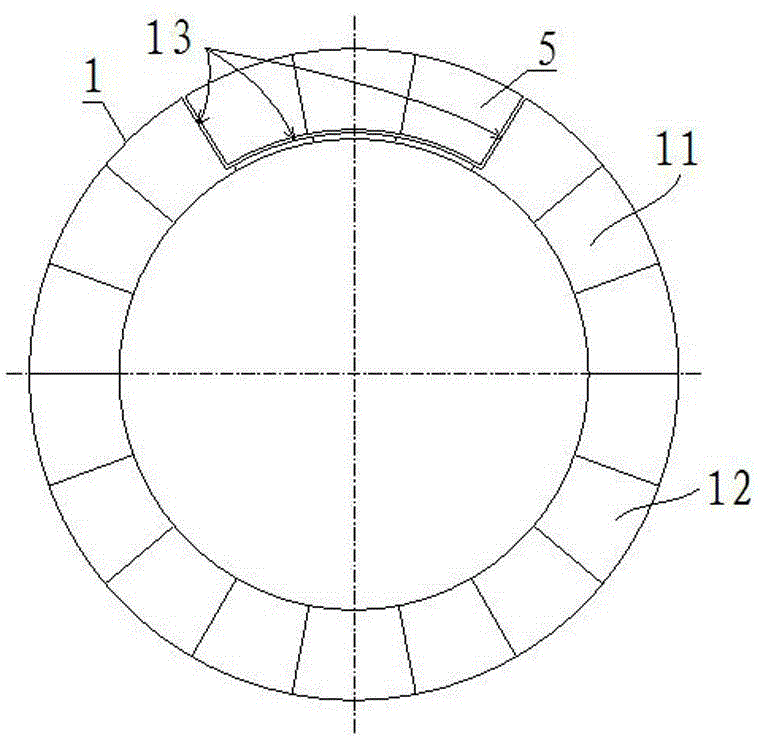

[0032] See image 3 , Image 6 and Figure 7 , Is a steam turbine exhaust steam diffusion and diversion structure of the present invention. The steam turbine includes a low pressure outer cylinder composed of a low pressure outer cylinder upper half 2 and a low pressure outer cylinder lower half. The low pressure outer cylinder upper half 2 has a fixed and integrated exhaust Steam cone 3. See also Figure 4 and Figure 5 , The exhaust steam diffuser and guide structure includes an exhaust steam guide ring 1 arranged in the low-pressure outer cylinder. The exhaust steam guide ring 1 is divided at the horizontal midplane to form upper and lower half rings 11, 12, The upper and lower half r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com