Miniature electromagnetic type vibration energy collector and manufacturing method thereof

An energy harvester, electromagnetic vibration technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

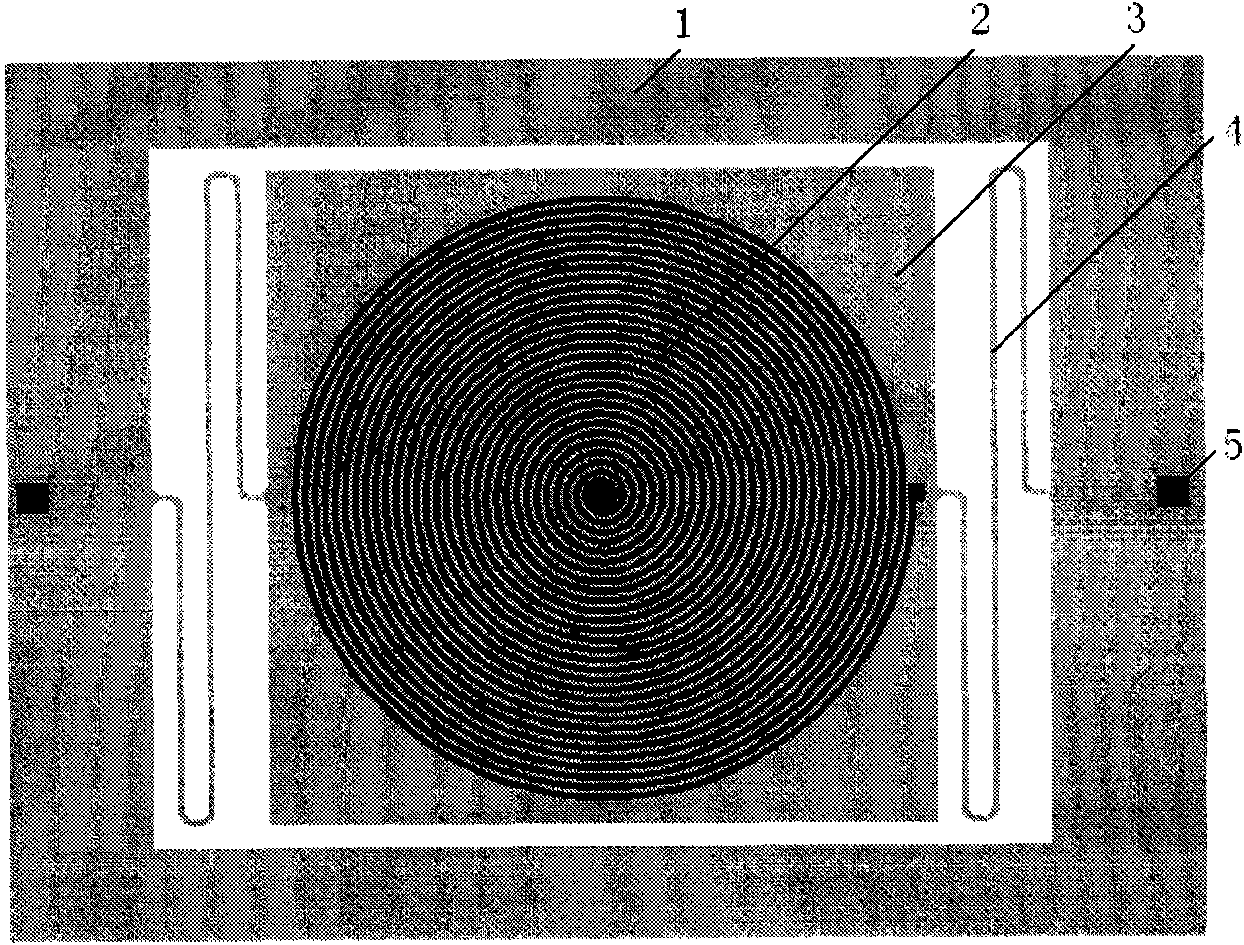

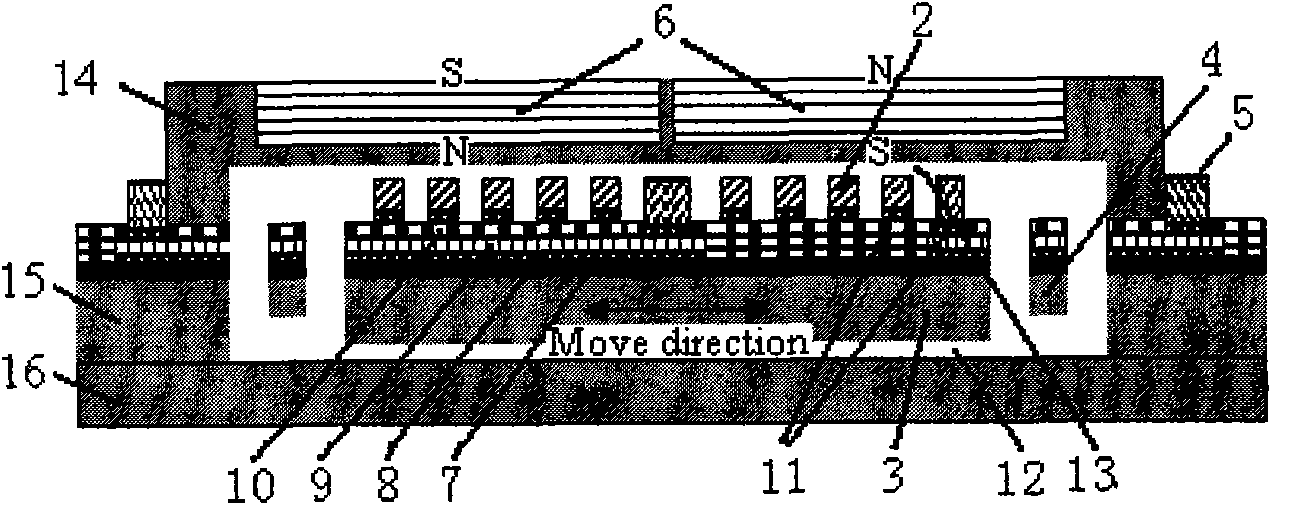

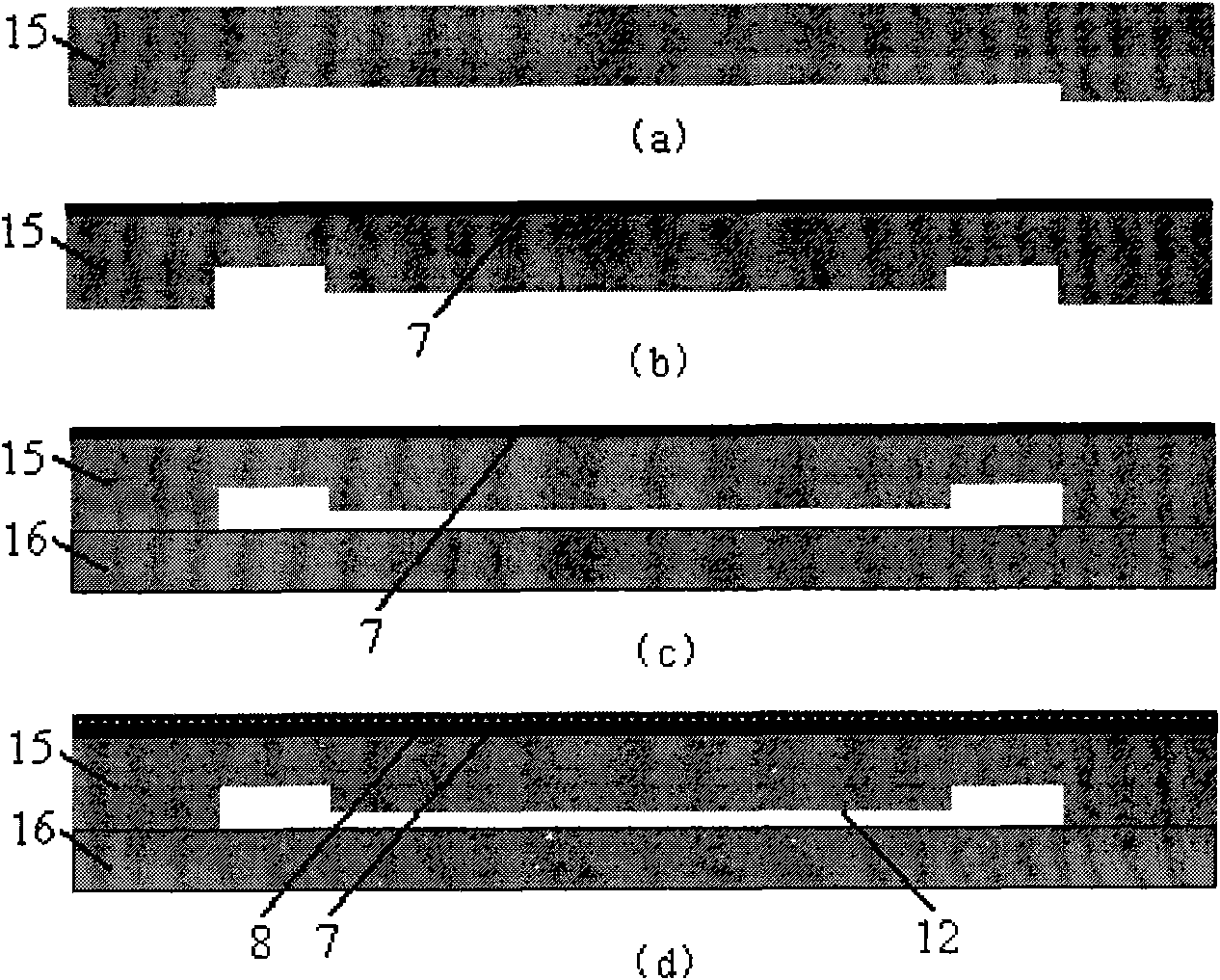

[0038] Embodiments of the present invention relate to energy harvester structures, combined with the attached figure 1 and 2 illustrate.

[0039] The top view of the structure of the energy harvester (without the upper cover and permanent magnet) is as follows figure 1 As shown, it mainly includes an external support frame 1, a planar spiral coil 2, electrodes 5, a central mass 3, and a folded elastic beam 4. The planar helical coil 2 is fabricated on the upper surface of the central mass 3 , and the central mass 3 is connected to the external support frame 1 through two folded elastic beams 4 . The structural section of the energy harvester is shown in figure 2 As shown, it mainly includes an upper cover silicon wafer 14, two permanent magnets 6, a vibration structure silicon wafer 15, and a substrate silicon wafer 16. Two permanent magnets 6 are placed side by side in the pits on the upper surface of the upper cover silicon wafer 14, and the directions of the magnetic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com