Method for manufacturing metal magnetic powder core can-type magnetic core and magnetic core with high direct current superposition characteristics

A pot-shaped magnetic core and magnetic powder core technology, applied in the field of metal soft magnetic powder, can solve the problems of difficulty in designing inductors, small winding filling factor, high temperature rise of the magnetic core, etc., to achieve good DC superposition characteristics, good Electromagnetic shielding properties, effect of low core loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

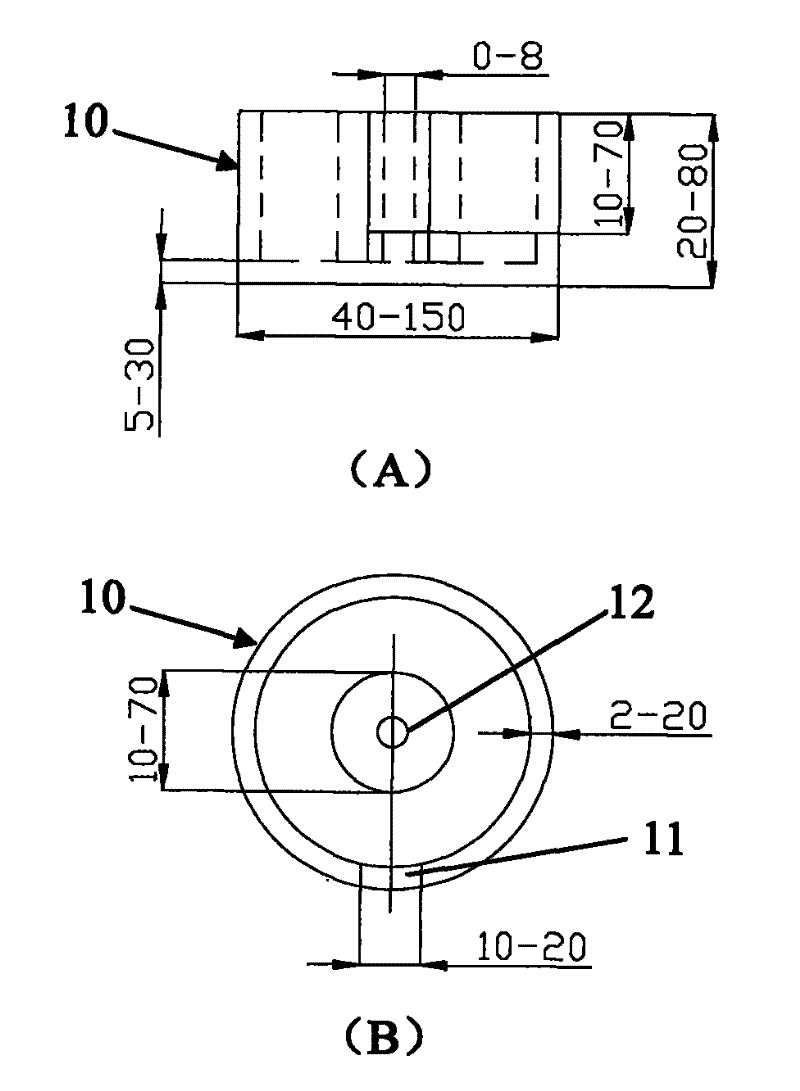

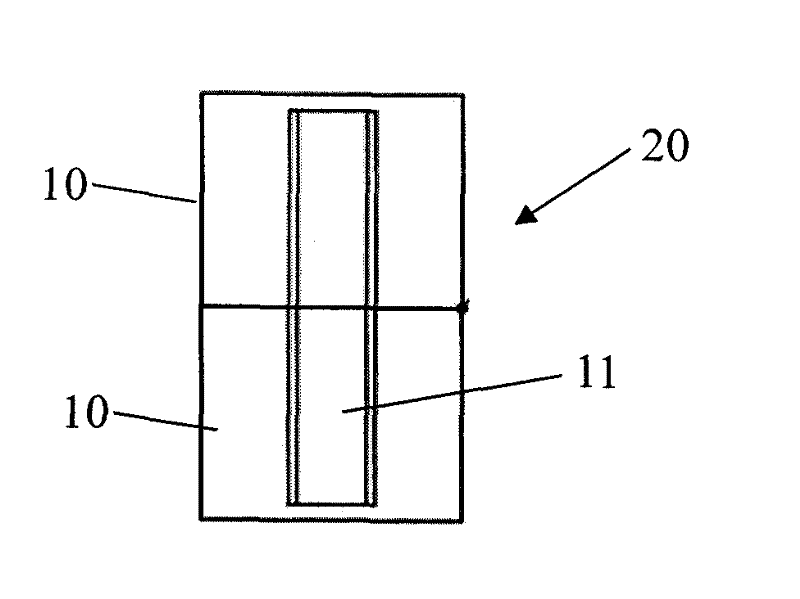

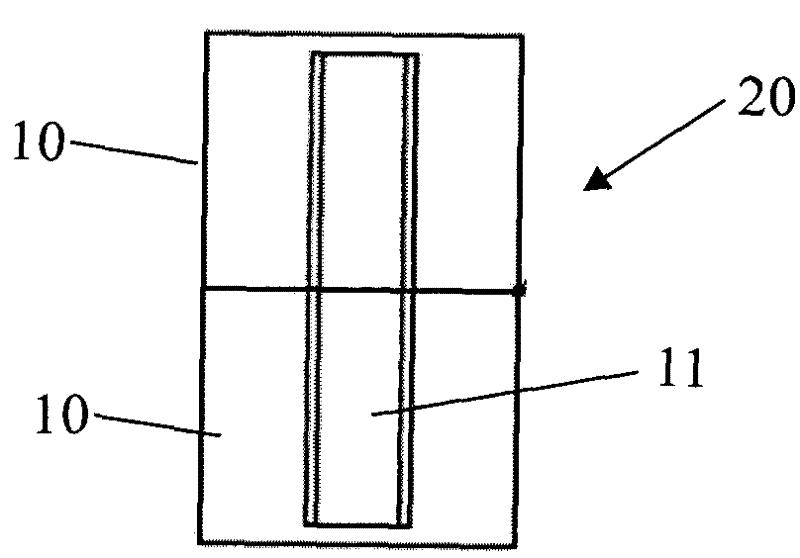

[0020] like figure 1 and figure 2 As shown, the present invention provides a metal magnetic powder core can-type magnetic core 10 made of metal soft magnetic powder, which is composed of one or more metal soft magnetic Including iron silicon aluminum, iron nickel, iron nickel molybdenum or iron silicon powder or their mixed powder, the powder is formed into a pot-shaped magnetic core after molding and heat treatment, and the specific product size is as follows figure 1 shown.

[0021] In the present invention, the metal soft magnetic powder used for making the pot-shaped magnetic core 10 is required as follows: the silicon content in the iron-silicon-aluminum is 8.5-9.8%, the aluminum is 5-8%, and the balance is iron. The nickel content in the iron-nickel powder is 40-55%, and the balance is iron. In the iron-nickel-molybdenum powder, nickel is 80-81%, molybdenum is 2-4%, and the balance is iron. The silicon content in the iron-silicon powder is 3-8%, and the balance is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com