Method for preparing miniature thermocouple probe of scanning thermal microscopy

A technology of scanning thermal microscope and thermocouple, which is applied in the field of nanometer sensors and nanometers to achieve the effect of simple process and low equipment dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings, but the present invention is not limited in any way.

[0036] In this example, the commercialized AFM contact mode silicon nitride tip is used, and titanium and palladium are selected as the two metal layer materials of the thermocouple to make a miniature thermocouple probe suitable for the cantilever mount of the VEECO D-3100 AFM instrument. ,Specific steps are as follows.

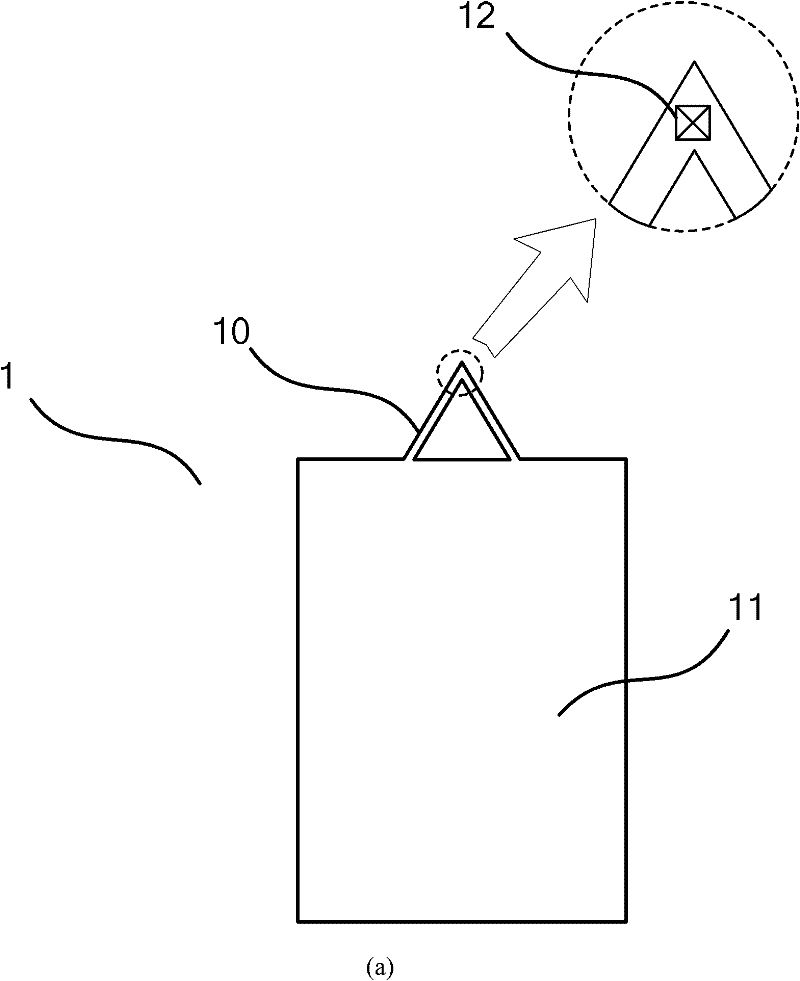

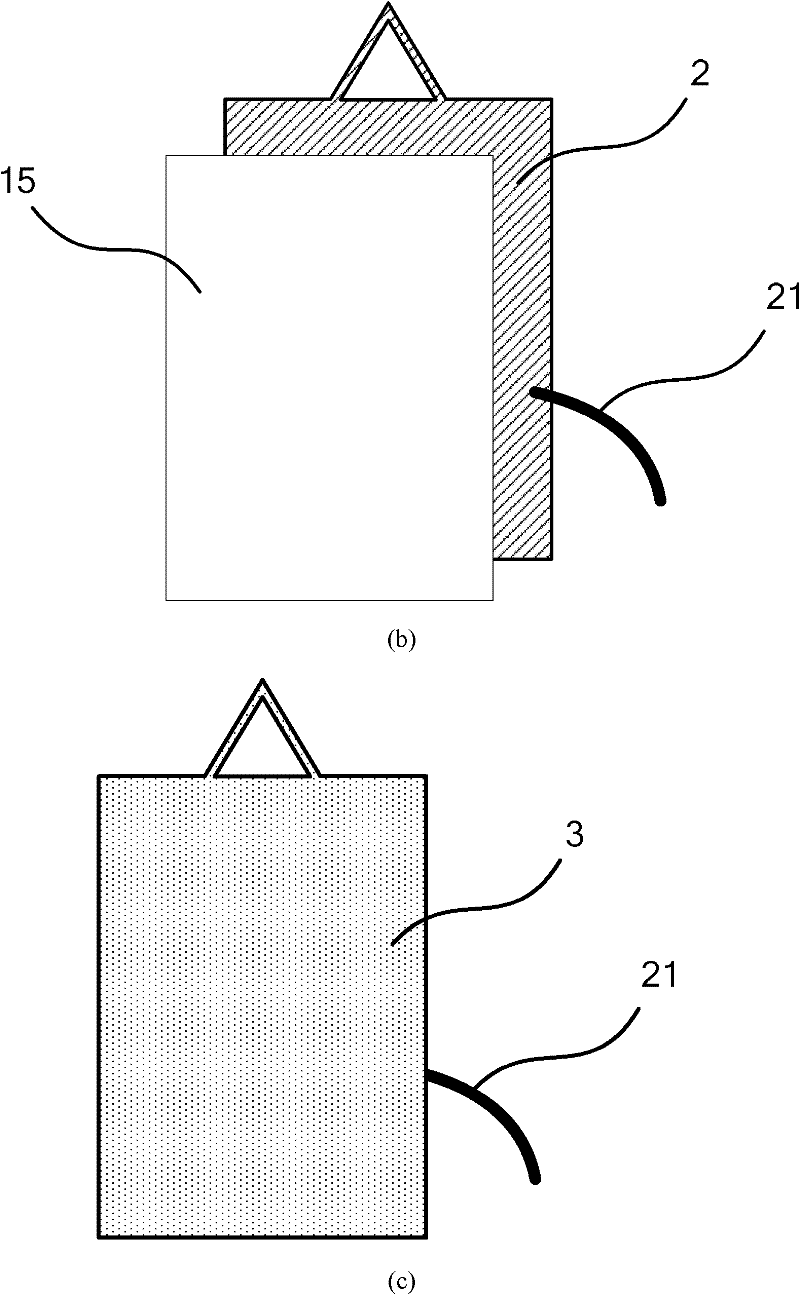

[0037] (a) Select the AFM cantilever needle tip (model DNP-20, VEECO, USA) that is conveniently available on the market ( figure 1 ), and a miniature thermocouple was prepared on the tip of one of the V-shaped cantilever needles. figure 2 It is a schematic diagram of the process of making a thermocouple. In order to simplify the expression, only one of the four needle points is actually drawn (such as figure 2 shown in a). In steps a and c, the metals used are sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com