Surface modification method for nano calcium carbonate

A nano calcium carbonate, surface modification technology, applied in fibrous filler, dyeing physical treatment, dyeing low molecular organic compound treatment and other directions, can solve the problem of no industrial application value, no breakthrough progress, complex modification process, etc. problems, to achieve the best surface modification effect, outstanding enhancement function, and good technical and economic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

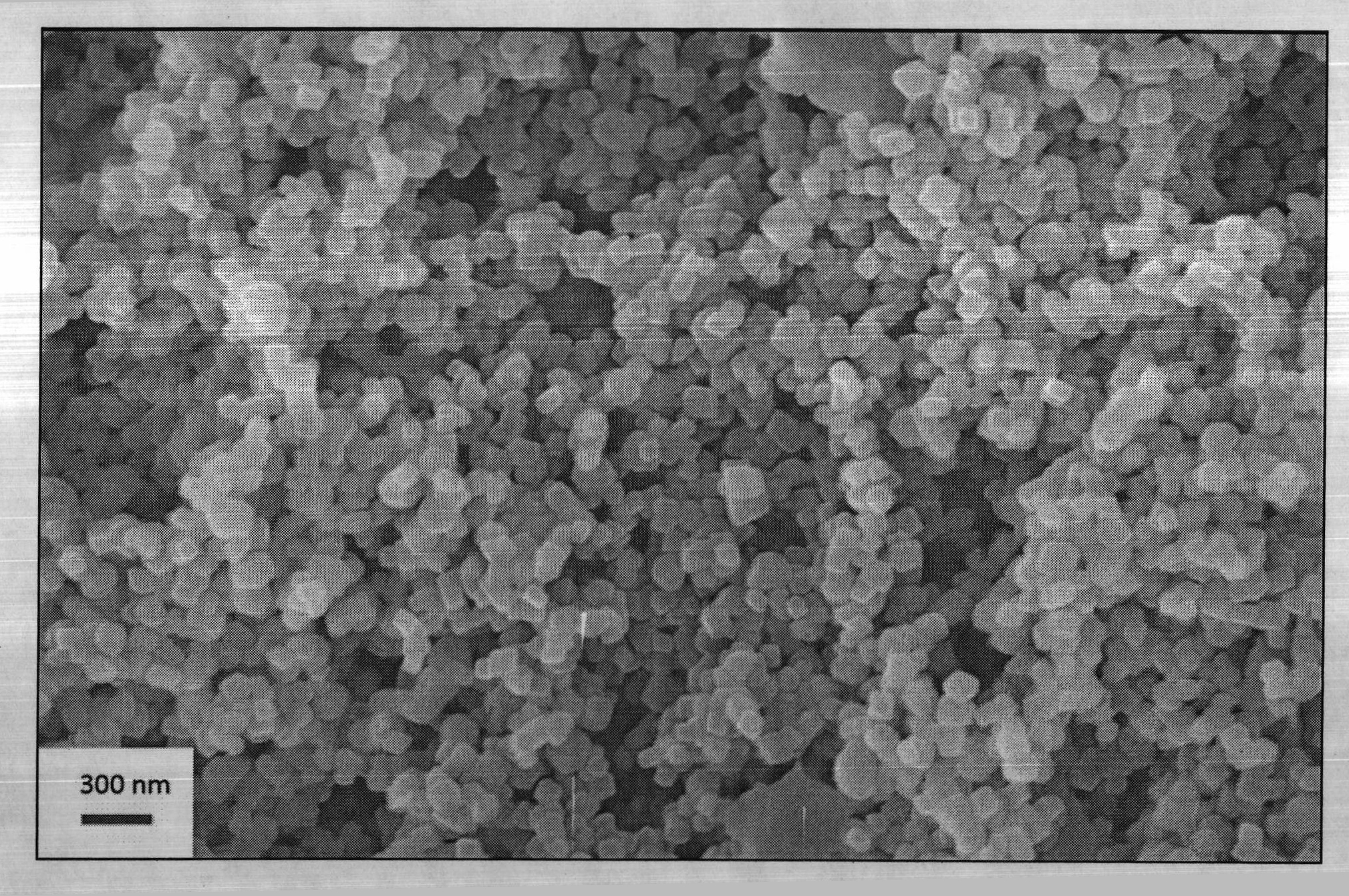

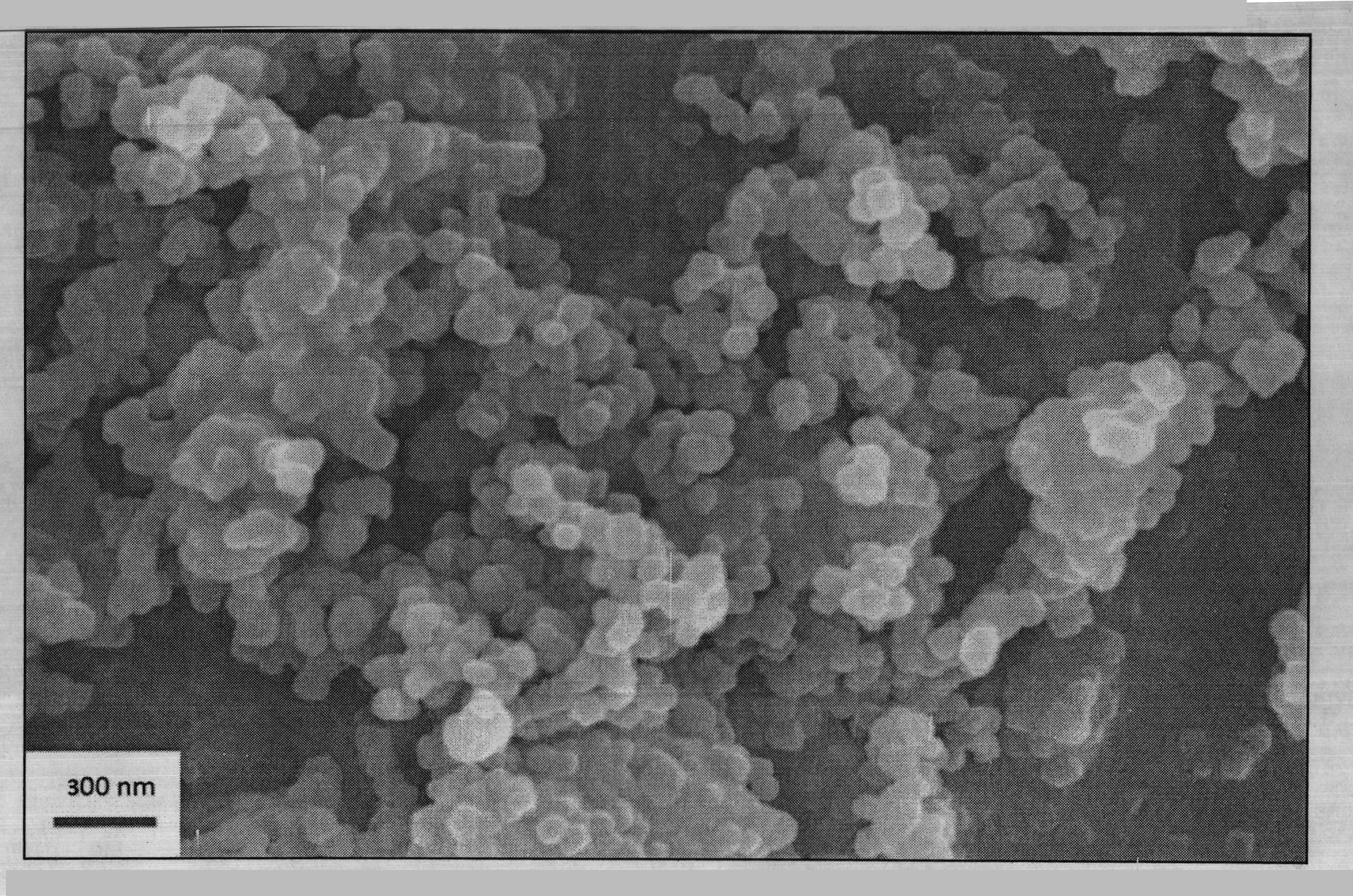

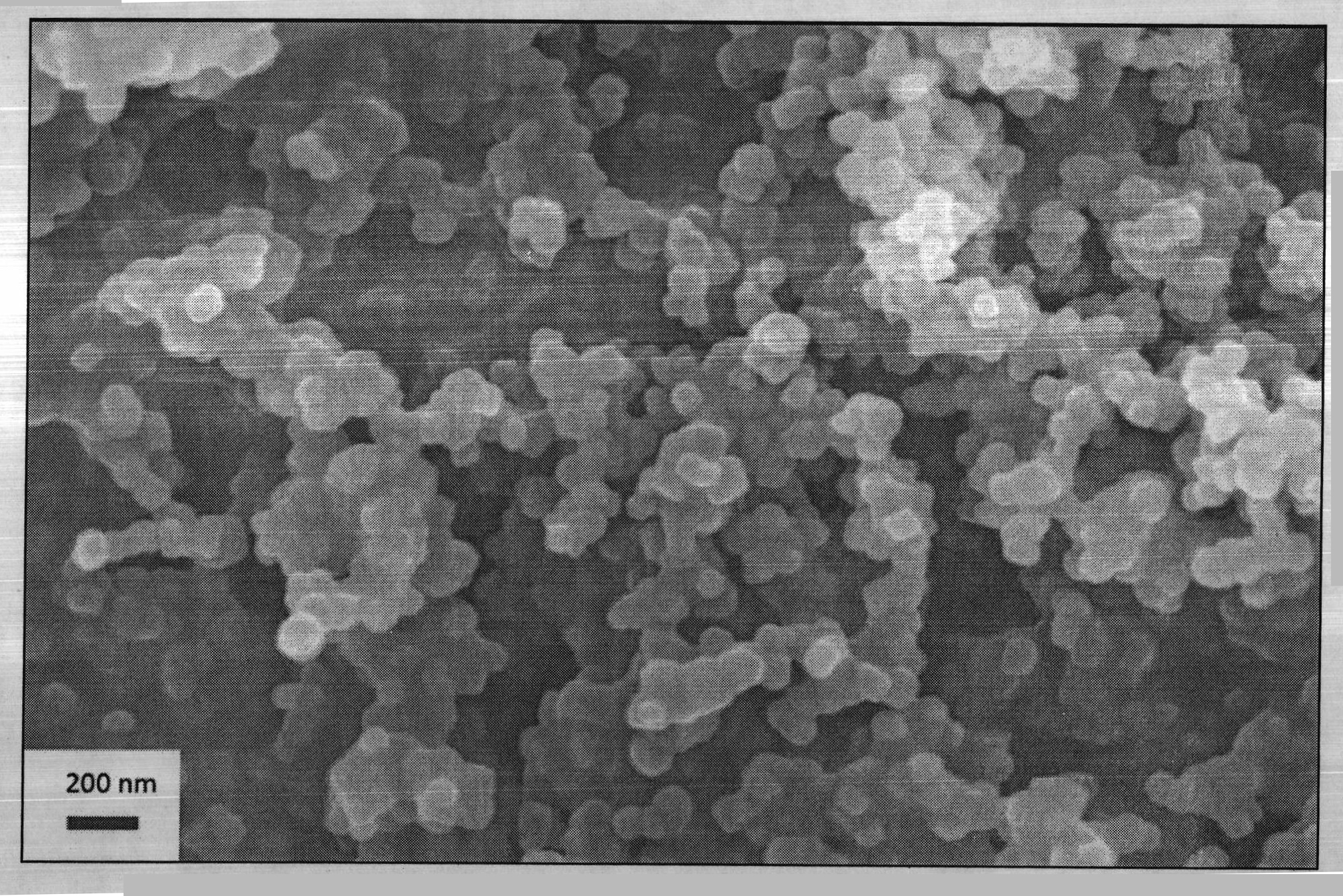

Image

Examples

Embodiment 1

[0037] The first step: adding 5.2g NaOH (0.00011mol / gCaCO 3 ) and apply continuous mechanical stirring, so that the alkali is evenly dispersed in the slurry and completely dissolved.

[0038] Step 2: Maintain mechanical stirring for the nano calcium carbonate slurry obtained in step 1 and rapidly heat to 90.0°C.

[0039] Step 3: under mechanical stirring, add 34.5g stearic acid (0.00010mol / gCaCO 3 ), and continued stirring for 60min.

[0040] Step 4: filtering, drying, pulverizing and depolymerizing the nano-calcium carbonate slurry obtained in the third step to obtain surface-modified nano-calcium carbonate.

Embodiment 2

[0042] The first step: adding 5.8g NaOH (0.00013mol / gCaCO in the newly prepared nano-calcium carbonate slurry of 11.5% in 10.0kg mass concentration 3 ) and apply continuous mechanical stirring, so that the alkali is evenly dispersed in the slurry and completely dissolved.

[0043] Step 2: Maintain mechanical stirring for the nano calcium carbonate slurry obtained in step 1 and rapidly heat to 90.0°C.

[0044] The 3rd step: under the assistance of mechanical stirring, add 34.5g palmitic acid (0.00012mol / gCaCO3) in the nano-calcium carbonate slurry obtained by the 2nd step 3 ), and continued to stir for 60 min.

[0045] Step 4: filtering, drying, pulverizing and depolymerizing the nano-calcium carbonate slurry obtained in the third step to obtain surface-modified nano-calcium carbonate.

Embodiment 3

[0047] Step 1: adding 5.2g NaOH (0.00011mol / gCaCO 3 ) and apply continuous mechanical stirring, so that the alkali is evenly dispersed in the slurry and completely dissolved.

[0048] Step 2: Maintain mechanical stirring for the nano calcium carbonate slurry obtained in step 1 and rapidly heat to 90.0°C.

[0049] The 3rd step: under the assistance of mechanical stirring, add the mixture (0.00010mol / gCaCO 3 ), and continued stirring for 60min.

[0050] Step 4: filtering, drying, pulverizing and depolymerizing the nano-calcium carbonate slurry obtained in the third step to obtain surface-modified nano-calcium carbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com