Highly transparent electronic encapsulating adhesive

A potting glue and electronic technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of low light transmittance, high production cost, and unfavorable mass promotion and use, so as to reduce production cost and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

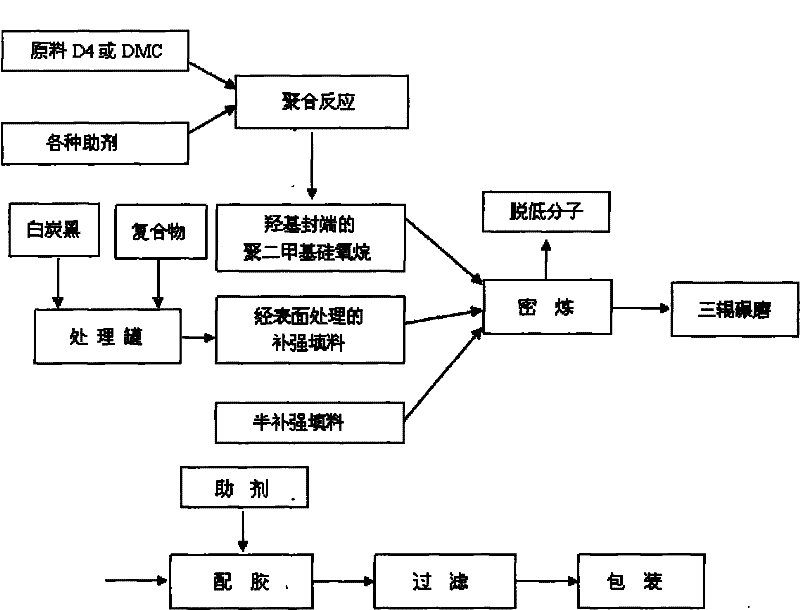

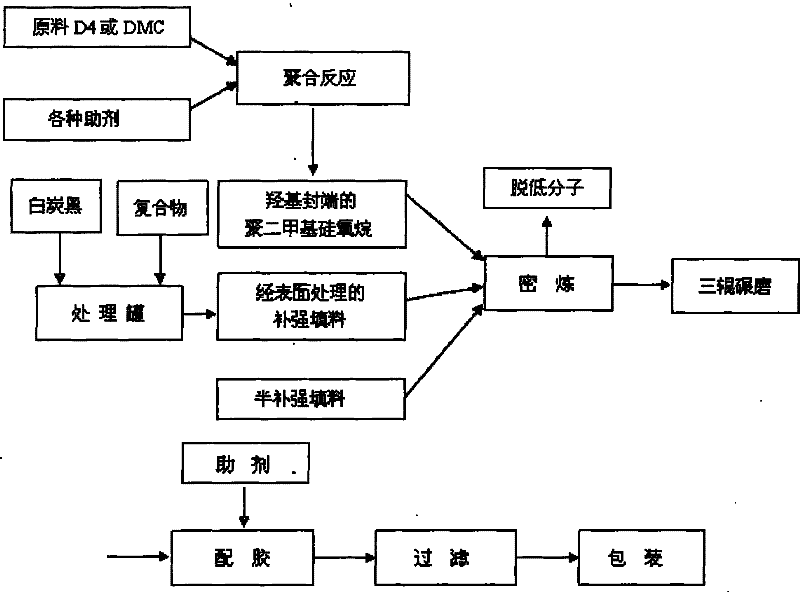

[0021] refer to figure 1 , the present invention is implemented like this:

[0022] exist figure 1 Among them, a highly transparent electronic potting compound is made by the following production steps:

[0023] 1), the basic polymer is made through the synthesis process of hydroxyl-terminated polydimethylsiloxane;

[0024] 2), the surface treatment process of reinforcing filler;

[0025] 3), the semi-finished rubber compound is made by the banburying process;

[0026] 4) Highly transparent electronic potting and sealing products are made by the glue compounding process.

[0027] The synthesis process of the polydimethylsiloxane terminated by the hydroxyl group is firstly in a special reaction kettle, drop into 98% content of D4 (octamethyltetrasiloxane ring body) or DMC (dimethylsiloxane alkane mixed ring body), then heat up to 60-65°C to remove water in a vacuum, then add various additives (including initiators, hydroxyl capping agents, etc.) Filtration becomes hydroxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com