Method for hydrolyzing organochlorosilane

An organochlorosilane and polysiloxane technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of large circulating acid water flow, easy to be carried out, incomplete hydrolysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

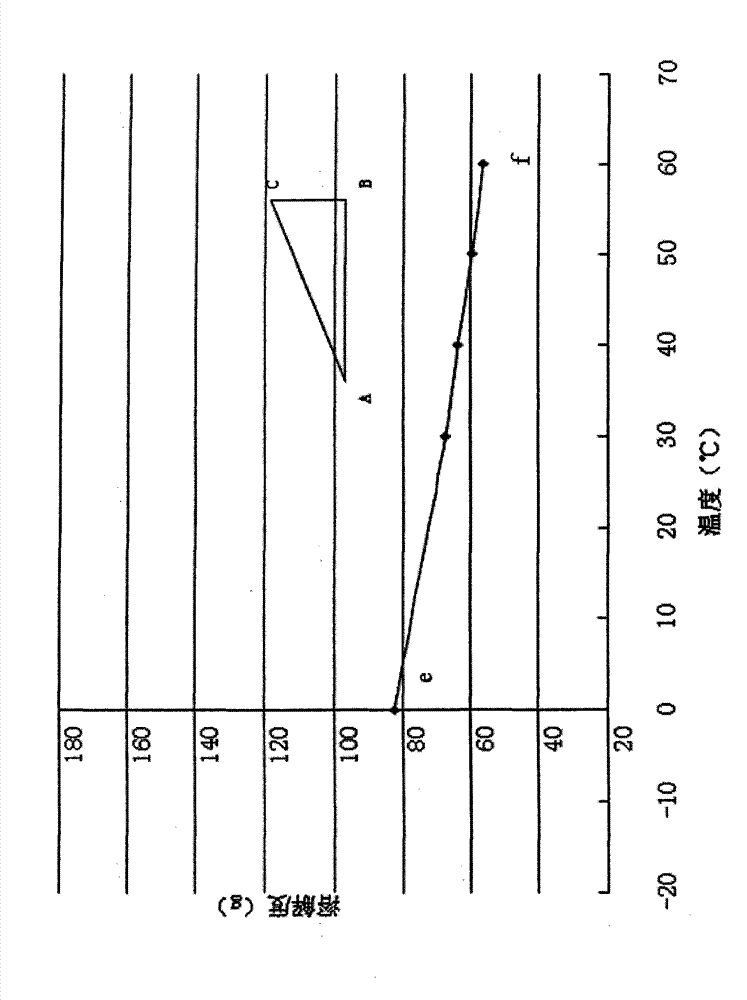

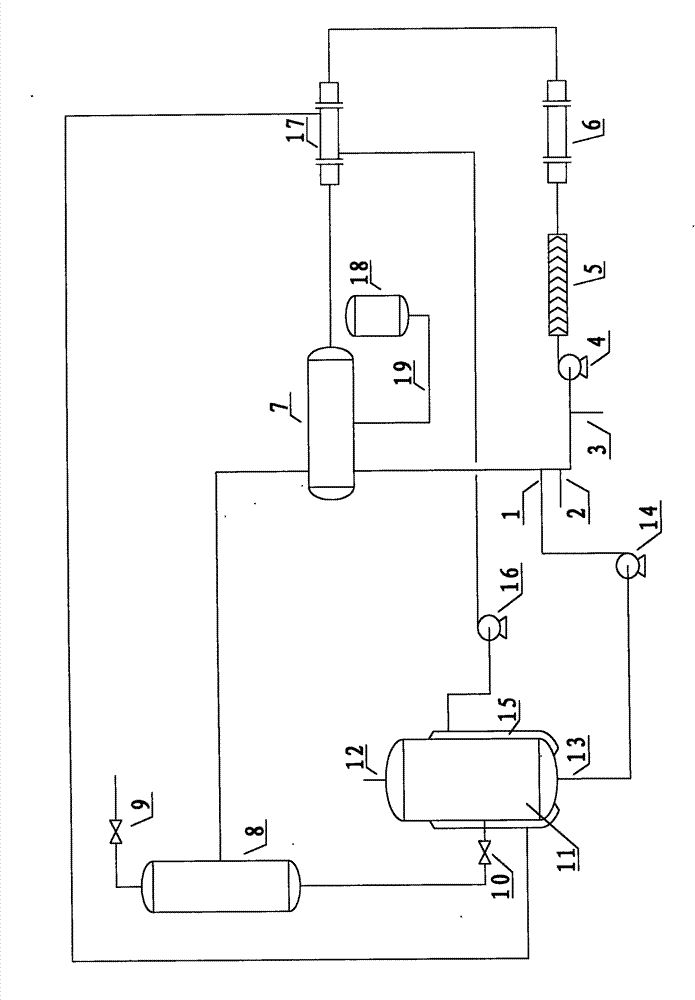

Embodiment 1

[0064] The organochlorosilane is trimethylchlorosilane, the amount of trimethylchlorosilane added to the hydrolysis system per hour is 0.670t, the amount of water added to the hydrolysis system per hour is 0.056t, and the amount of circulating acid water entering the hydrolysis system per hour is 1.089 t, the hydrolysis temperature is controlled at 40°C, the hydrolysis pressure is controlled at an absolute pressure of 1.10MPa, and the flow rate of the circulation pump of the hydrolysis system is 50m per hour 3 , hydrolysis produces high concentration (mass concentration is about 54%) unsaturated acid water and hexamethyldisiloxane; adjust the internal heat exchange system of the hydrolysis system and the desorption kettle, under the desorption pressure is an absolute pressure of 0.10MPa, The elution temperature was controlled at 0°C. The circulation ratio is (50-1.815) / 1.815; the high-concentration unsaturated acid water and hexamethyldisiloxane are overflowed into the seconda...

Embodiment 2

[0066] The organochlorosilane is a mixture of dimethylhydrochlorosilane and trimethylchlorosilane with a molar ratio of 75:2. The amount of organochlorosilane added to the hydrolysis system per hour is 0.948t, and the amount of water added to the hydrolysis system per hour is 0.147t. The amount of circulating acid water entering the hydrolysis system per hour is 3.769t, the hydrolysis temperature is controlled at 25°C, the hydrolysis pressure is controlled at an absolute pressure of 1.10MPa, and the flow rate of the circulation pump of the hydrolysis system is 50m per hour 3 , hydrolysis produces high concentration (calculation result is about 53%) unsaturated acid water and polymethylhydrogen siloxane; adjust the internal heat exchange system of the hydrolysis system and the desorption kettle, under the desorption pressure is an absolute pressure of 0.10MPa, The elution temperature was controlled at -10°C. The high-concentration unsaturated acid water and polymethylhydrogensi...

Embodiment 3

[0068] The organochlorosilane is selected from dimethyldichlorosilane, the amount of dimethyldichlorosilane added to the hydrolysis system per hour is 0.872t, the amount of water added to the hydrolysis system per hour is 0.122t, and the amount of circulating acid water entering the hydrolysis system per hour is 2.385t, the hydrolysis temperature is controlled at 40°C, the hydrolysis pressure is controlled at an absolute pressure of 1.10MPa, and the flow rate of the circulation pump of the hydrolysis system is 50m per hour 3 , hydrolysis produces high concentration (calculated result is about 53%) unsaturated acid water and dimethyl dichlorosilane hydrolyzate; adjust the internal heat exchange system of the hydrolysis system and the desorption kettle, and the desorption pressure is under the absolute pressure of 0.10MPa , so that the elution temperature was controlled at 0°C. The high-concentration unsaturated acid water and dimethyldichlorosilane hydrolyzate overflow into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com