Material recycling technique used during sulfur tetrafluoride production

A technology of sulfur tetrafluoride and raw materials, which is applied in the direction of sulfur and halogen compounds, can solve the problems of increased purification treatment costs, loss of raw materials, high production costs, etc., and achieve the effect of reducing purification treatment volume, production costs and product losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The first step to recycle:

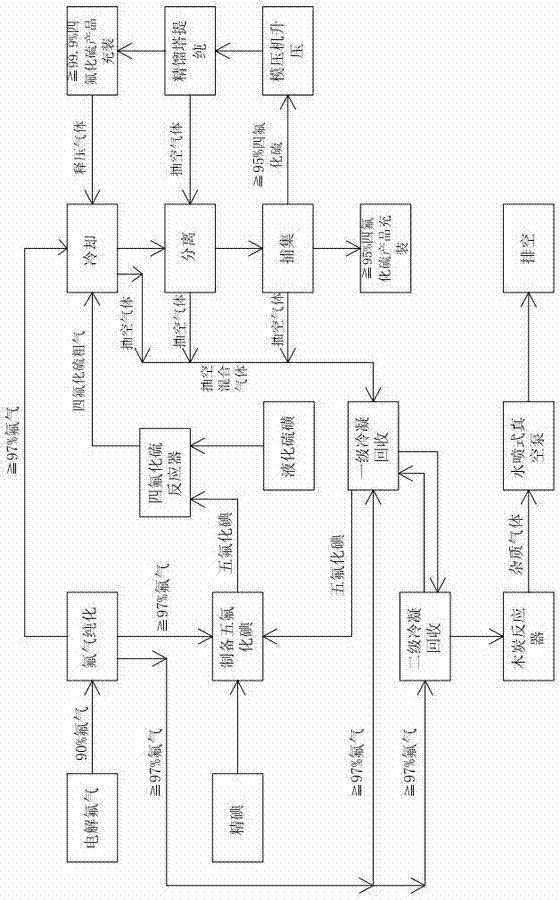

[0025] It is synthesized by reacting iodine pentafluoride and sulfur in a sulfur tetrafluoride reactor to obtain crude sulfur tetrafluoride gas.

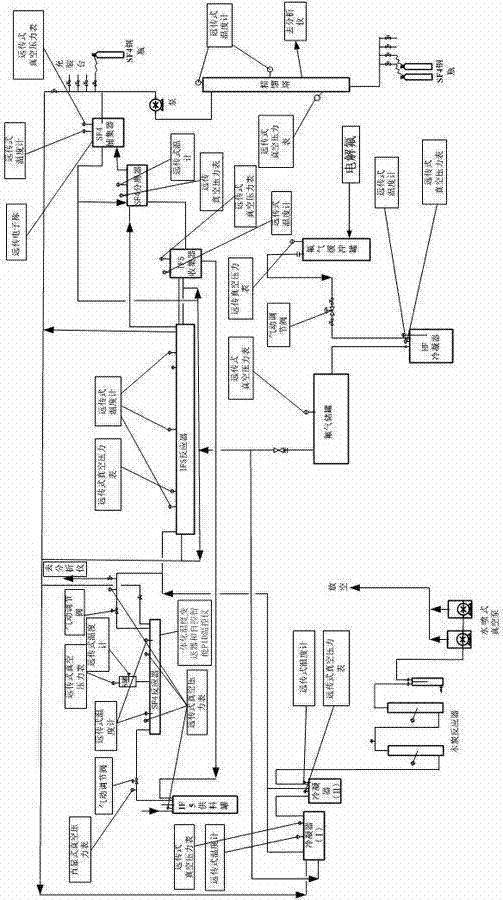

[0026] The separation and capture of sulfur tetrafluoride is that the iodine pentafluoride and iodine in the sulfur tetrafluoride crude gas are cooled by the condenser, condensed and retained by the condensing separator, and the liquid iodine pentafluoride is recycled for the reaction of sulfur tetrafluoride , the solid iodine is fed into the fluorine gas to react to produce iodine pentafluoride liquid, which flows back to be recycled for the sulfur tetrafluoride reaction; the sulfur tetrafluoride gas in the crude sulfur tetrafluoride gas is condensed and liquefied by the condensation trap, and the resulting purity is 95% of primary sulfur tetrafluoride products are directly loaded into steel cylinders by means of liquid input, and the pressure is controlled by a remote pressure sensor to 0.05Mpa;...

Embodiment 2

[0028] The first step to recycle:

[0029] It is synthesized by reacting iodine pentafluoride and sulfur in a sulfur tetrafluoride reactor to obtain crude sulfur tetrafluoride gas.

[0030] The separation and capture of sulfur tetrafluoride is that the iodine pentafluoride and iodine in the sulfur tetrafluoride crude gas are cooled by the iodine pentafluoride reactor, condensed and retained by the condensation separator, and the liquid iodine pentafluoride is used for tetrafluoride The sulfur reaction is recycled, and the solid iodine is fed into the fluorine gas to react to produce iodine pentafluoride liquid, which flows back to the sulfur tetrafluoride reaction and recycled; the sulfur tetrafluoride gas in the crude sulfur tetrafluoride gas is condensed and liquefied through the condensation trap , to produce primary sulfur tetrafluoride products with a purity of 99%, which are directly loaded into steel cylinders by means of liquid input, and the pressure is controlled by ...

Embodiment 3

[0032] The first step to recycle:

[0033] It is synthesized by reacting iodine pentafluoride and sulfur in a sulfur tetrafluoride reactor to obtain crude sulfur tetrafluoride gas.

[0034] The separation and capture of sulfur tetrafluoride is that the iodine pentafluoride and iodine in the sulfur tetrafluoride crude gas are cooled by the iodine pentafluoride reactor, condensed and retained by the condensation separator, and the liquid iodine pentafluoride is used for tetrafluoride The sulfur reaction is recycled, and the solid iodine is fed into the fluorine gas to react to produce iodine pentafluoride liquid, which flows back to the sulfur tetrafluoride reaction and recycled; the sulfur tetrafluoride gas in the crude sulfur tetrafluoride gas is condensed and liquefied through the condensation trap , to produce primary sulfur tetrafluoride products with a purity of 97%, which are directly loaded into steel cylinders by means of liquid input, and the pressure is controlled by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com