Method of loading a crystallization device

A crystallization device and crystallization technology, which is applied in peptide preparation methods, crystallization dishes, separation methods, etc., can solve the problems of easy errors in the weighing process, inappropriate limited quantities, etc., and achieve high flexibility, convenience, and flexibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

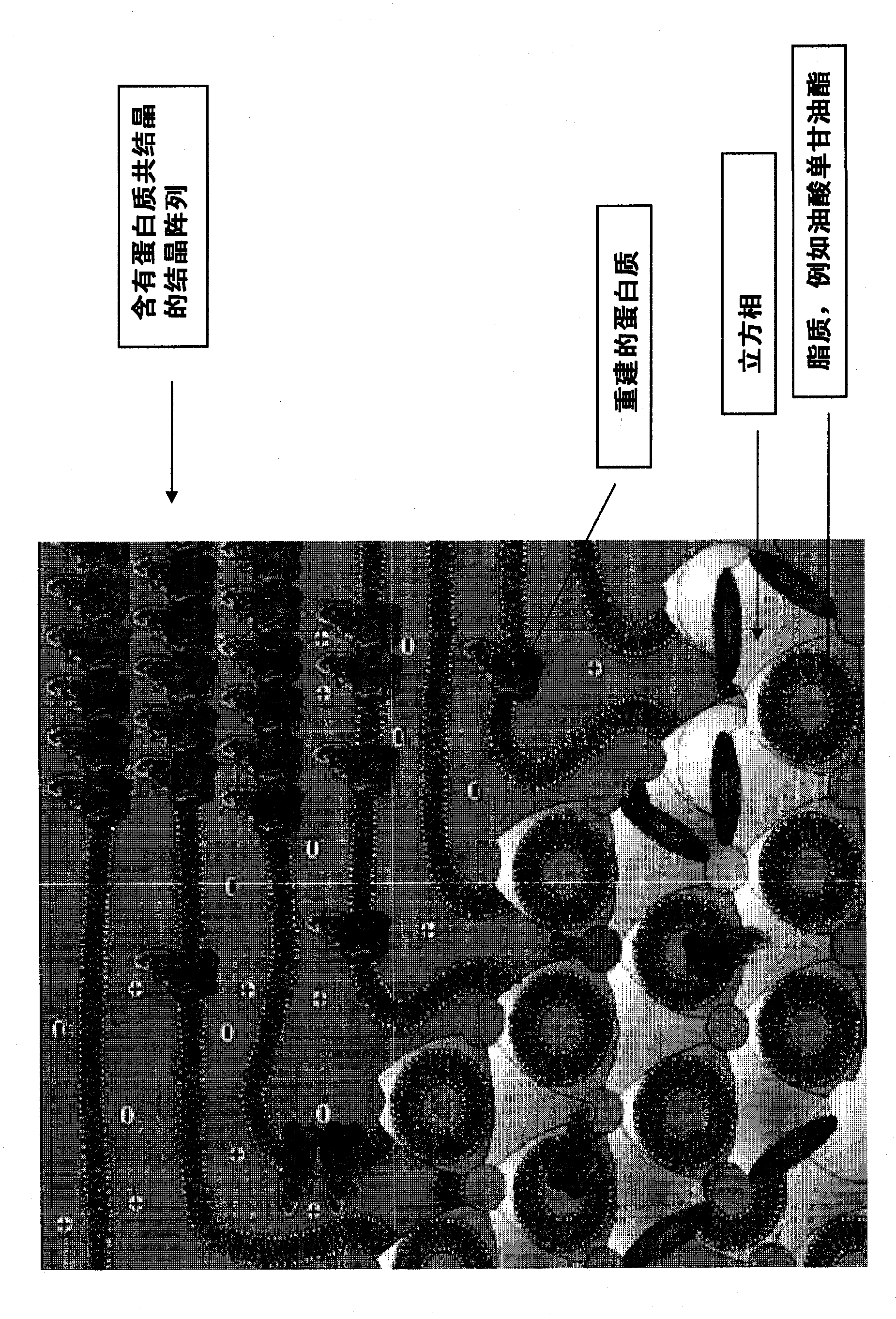

[0040] According to one embodiment, the crystallization device is a protein crystallization plate. Preferably the plate is in porous form. A suitable crystallization apparatus and suitable embodiments thereof are described in detail above; reference is made above.

[0041] According to one embodiment, the matrix-forming compound capable of forming a membrane protein crystallization matrix has at least one of the following properties:

[0042] a) capable of forming a mesophase; and / or

[0043] b) capable of forming a cubic phase; and / or

[0044] c) capable of forming a sponge phase; and / or

[0045] d) is a lipid; and / or

[0046] e) is amphiphilic; and / or

[0047] f) contains saturated or unsaturated fatty acid chains; and / or

[0048] g) are alcohol derivatives of fatty acids.

[0049] Further details regarding these compounds, suitable mixtures and compositions comprising additives are discussed in detail above in connection with the loading method, and apply equally to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com