Bar-shaped no-excitation tap switch with gear positioning

A tap changer, bar-shaped technology, used in transformers, electrical components, variable inductors, etc., can solve the problem of contact burnout, incomplete operation of moving contacts, and inability to ensure accurate rack displacement. In place and other problems, to achieve the effect of strong feel and avoid contact burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

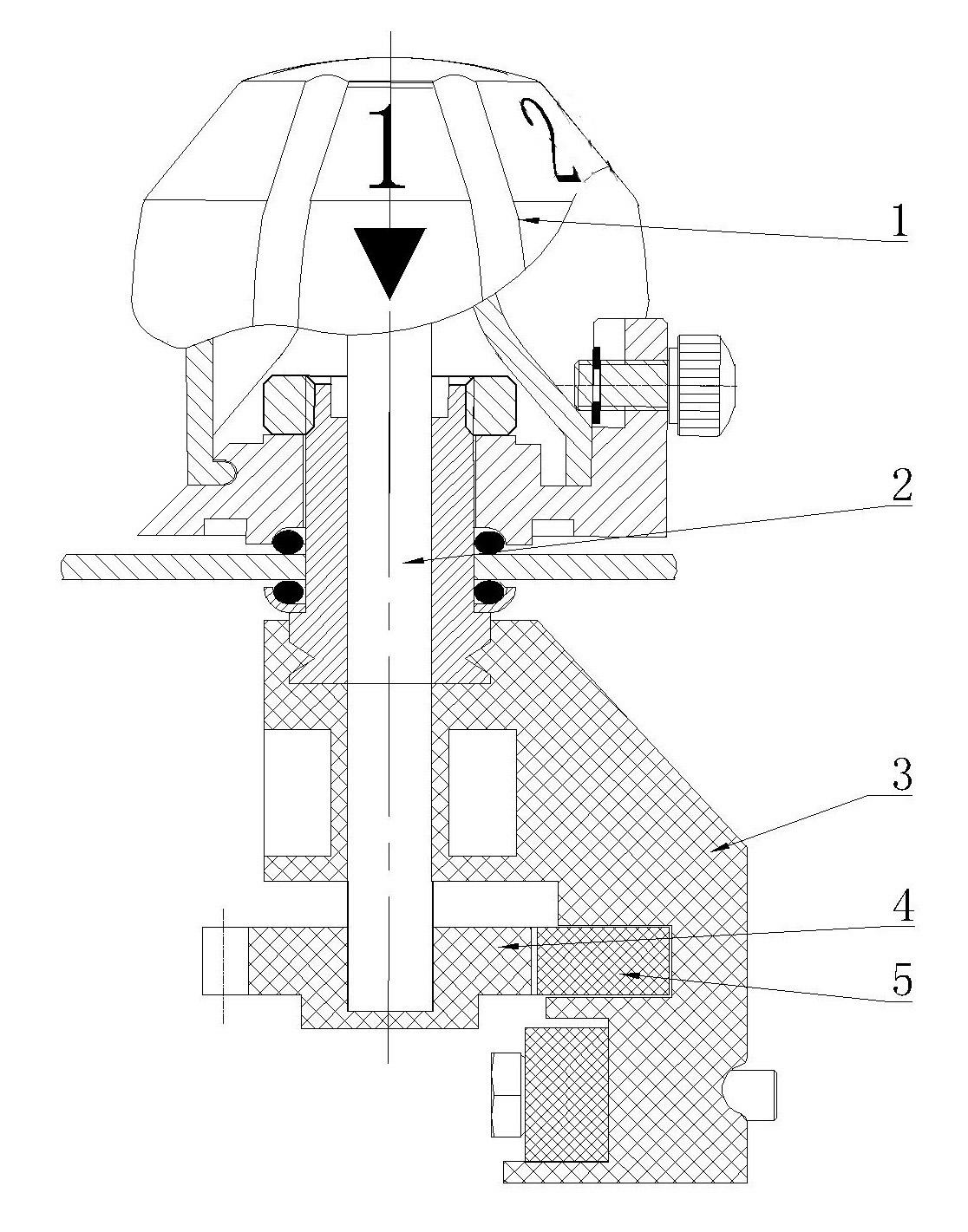

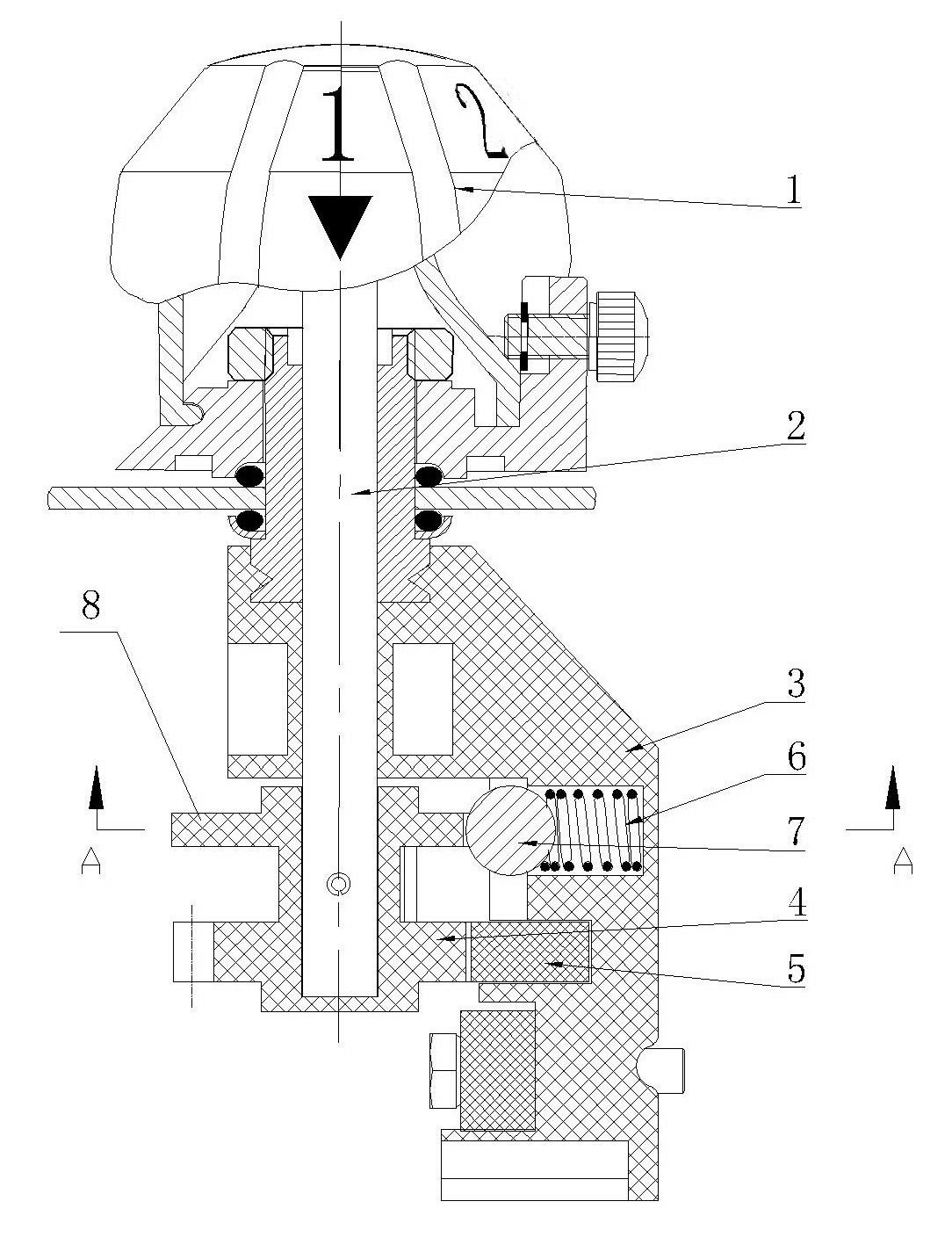

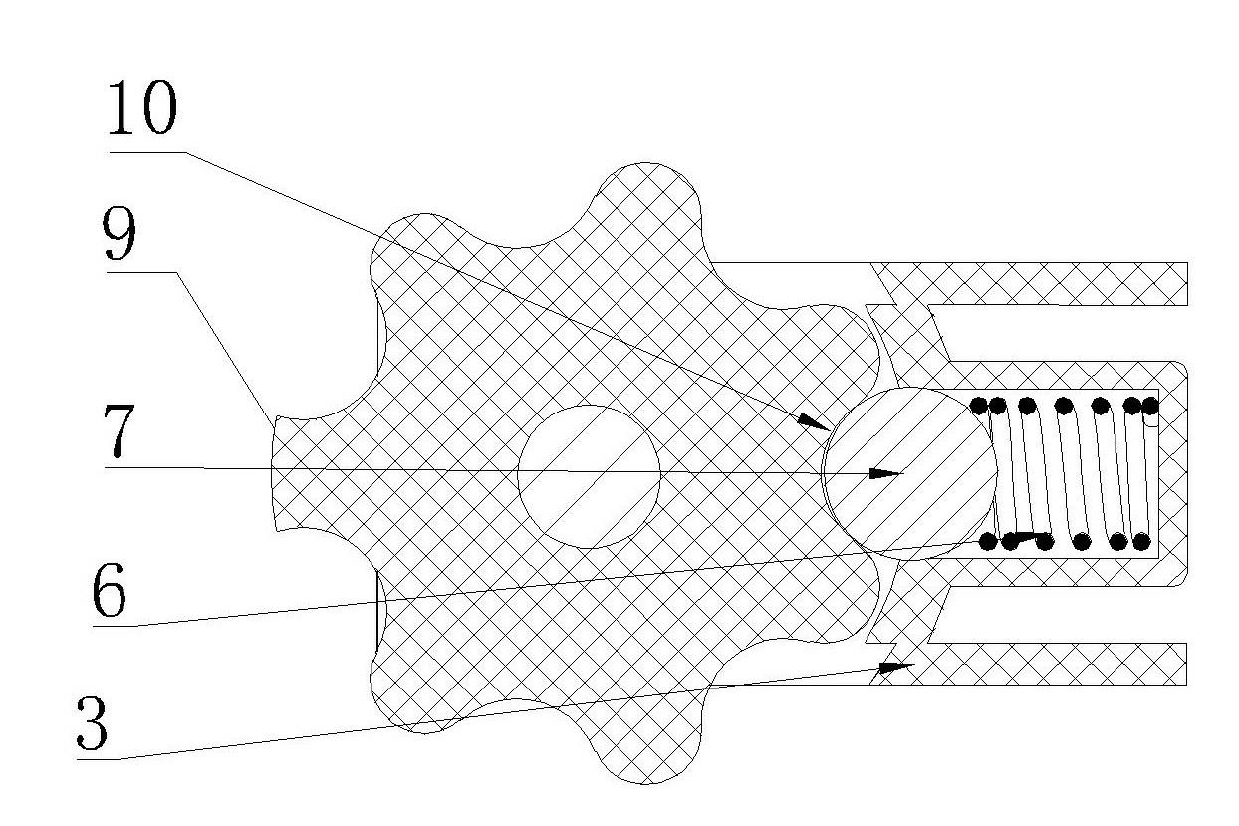

[0010] see figure 2 , which includes a handle 1, a drive shaft 2 and a bracket 3, the drive shaft is coaxial with the drive gear 4, the drive gear is meshed with the rack 5, and a blind hole is set on the bracket 3, and springs 6 are sequentially installed in the blind hole from inside to outside and the positioning bead 7; the positioning gear 8 is coaxial with the drive shaft 2, and said coaxial means that the shaft of the positioning gear is rigidly connected with the two shafts of the drive shaft, or the drive shaft is also the shaft of the positioning gear. In this embodiment, the drive shaft simultaneously As the driving gear 4 shafts and the positioning gear 8 shafts, and the positioning gear 8 is on the top and the driving gear 4 is on the bottom, the two are integrated structures. see image 3 The so-called positioning gear means that the teeth are wave-shaped. When there is no external force, the positioning beads fall into the trough of the positioning gear and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com