Valve plug of height adjustment reversing valve and girth welding process thereof for height adjustment system of coal mining machine

A technology of shearer and reversing valve, applied in mechanical equipment, earthwork drilling, slitting machinery, etc., can solve the problems of reducing the effective cross-sectional area of welding seam, discounting the strength of welding seam, affecting product quality, etc. The effect of unrestricted space, good welding quality and convenient welding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

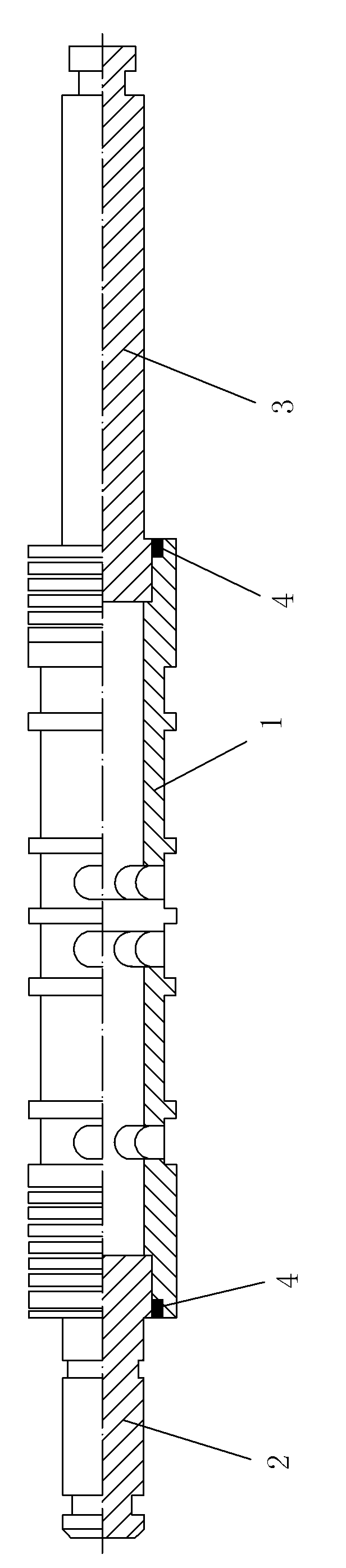

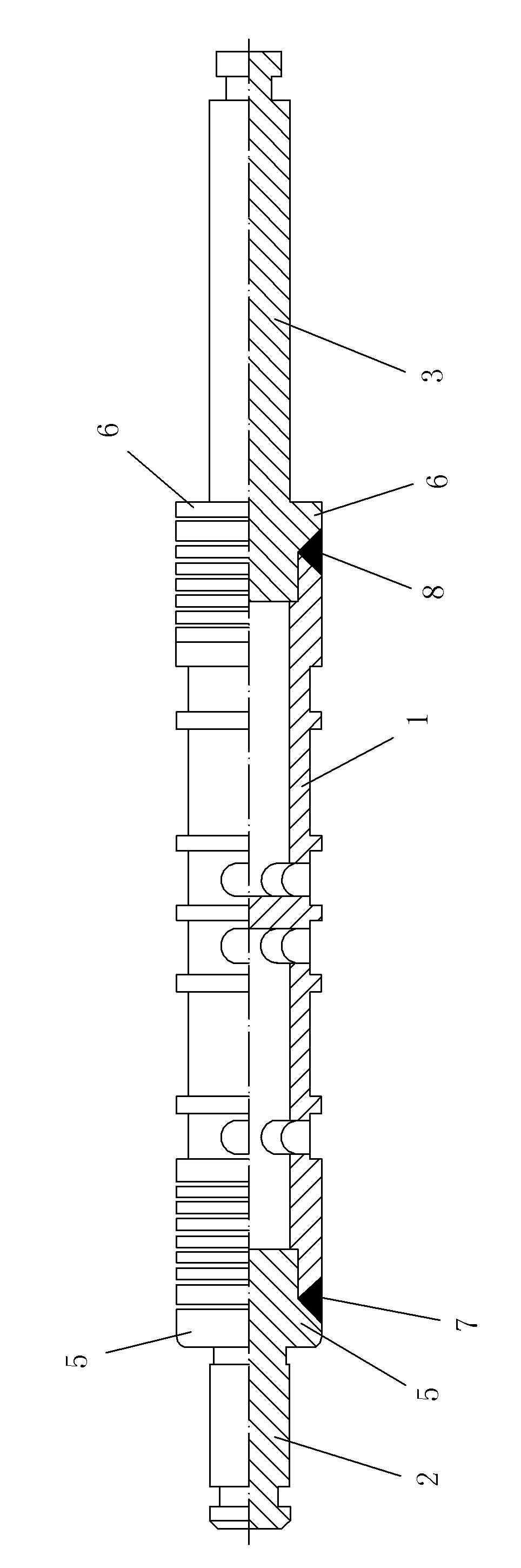

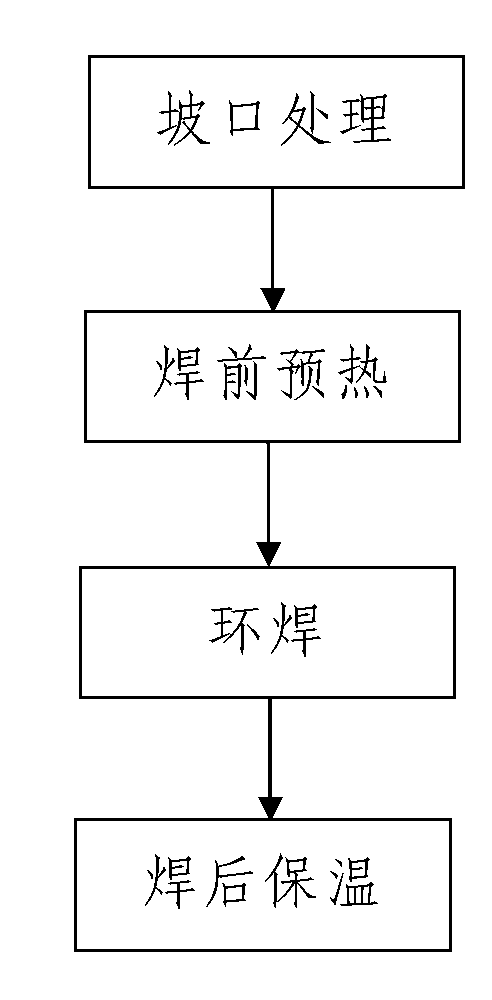

[0040] Such as figure 2 The height adjustment reversing valve spool for a shearer height adjustment system shown includes a valve core body 1 and two left core heads 2 and right core heads 3 respectively installed at the left and right ends of the valve core body 1, The valve core body 1 is a hollow cylindrical tube, the left core head 2 and the right core head 3 are solid cylindrical rods and the two are arranged coaxially with the valve core body 1, the valve core body 1 and the left core head 2 and the right core The heads 3 are all made of 35CrMo material. The left core head 2 and the right core head 3 are respectively inserted into the inner sides of the left and right ends of the valve core body 1. The installed cylindrical insertion port, the diameter of the cylindrical insertion port is greater than the inner diameter of the valve core body 1, and the inner ends of the left core head 2 and the right core head 3 are all correspondingly arranged to match the cylindrica...

Embodiment 2

[0058] In this embodiment, the height-adjusting reversing valve spool structure processed is different from Embodiment 1 in that: the transverse width of the annular welding seam one 7 and the annular welding seam two 8 (specifically, the top transverse width Width) is 4mm and the longitudinal depth of the two is 4mm, and the structure and positional relationship of the remaining parts are all the same as in Example 1.

[0059] In this embodiment, the difference in the girth welding process for the girth welding of the spool of the height-adjusting reversing valve from that of Embodiment 1 is that the V-shaped groove angle in step 1 is 50°, and the V-shaped groove angle is 50°. The horizontal width of the top of the mouth is 4mm and its longitudinal depth is 4mm; when preheating before welding in step 2, the surface temperature of the welding part is heated to 310°C and then stop preheating; when actually welding in step 3, the welding current The welding voltage is 190A, the ...

Embodiment 3

[0061] In this embodiment, the height-adjusting reversing valve spool structure processed is different from Embodiment 1 in that: the transverse width of the annular welding seam one 7 and the annular welding seam two 8 (specifically, the top transverse width Width) is 4mm and the longitudinal depth of the two is 4mm, and the structure and positional relationship of the remaining parts are all the same as in Example 1.

[0062] In this embodiment, the girth welding process for the height-adjusting reversing valve spool is different from that of embodiment 1 in that the bevel angle of the V-shaped bevel described in step 1 is 55°, and the V-shaped bevel The horizontal width of the top of the mouth is 4mm and its longitudinal depth is 4mm; when preheating before welding in step 2, the surface temperature of the welding part is heated to 320°C and then stop preheating; when actually welding in step 3, the welding current The welding voltage is 200A, the welding voltage is 17V, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com