Foldable protective barrier near side of building

A border protection, folding technology, applied in the direction of construction, building structure, building materials processing, etc., can solve the problems of cumbersome installation and disassembly, inconvenient transportation, etc., to save transportation space, reduce weight and storage space, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

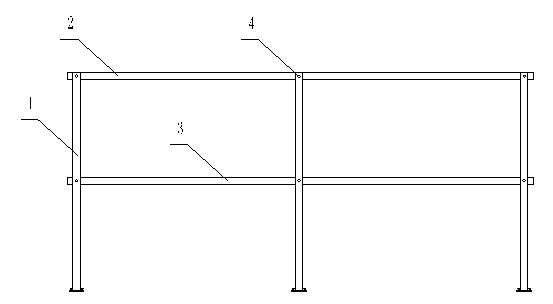

[0016] Such as figure 1 As shown, the present invention provides a kind of building edge protective railing, comprises the column 1 that is made by the commonly used steel pipe of φ48X3. The expansion bolts on the fixing seat fix the column 1 on the floor. The upright column 1 is connected with the top cross bar and the middle section cross bar 3 by hinges 4 . The column 1, the top cross bar 2 and the middle cross bar 3 form a parallelogram structure through the hinge 4, which can be folded and placed during transportation and storage, saving a lot of space.

Embodiment 2

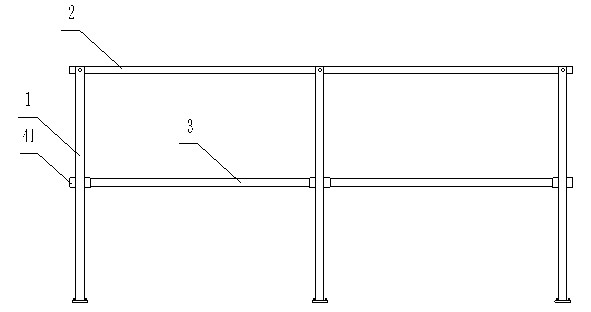

[0018] Such as figure 2 As shown, the structure of embodiment 2 is basically the same as that of embodiment 1, wherein the hinge 4 is still used to connect the column 1 and the top cross bar 2. The difference is that in this embodiment, a steel pipe is welded in the middle section of the column 1 as a connecting cylinder 41. The connecting cylinder 41 has a diameter of 41 mm, and the middle crossbar 3 is inserted into the connecting cylinder 41 to form a guardrail. During transportation and storage, the column 1 and the top cross bar 2 are folded and stored, while the middle cross bar 3 is stored separately.

Embodiment 3

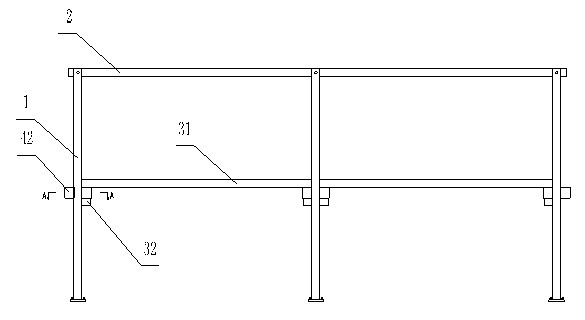

[0020] Such as image 3 , Figure 4 As shown, the structure of embodiment 3 is basically the same as that of embodiment 1, wherein the hinge 4 is still used to connect the column 1 and the top cross bar 2, and the difference is that a steel pipe is welded in the middle section of the column 1 as a connecting cylinder in this embodiment 42. The connecting cylinder 42 has a diameter of 41 mm, and the connecting cylinder 42 is provided with a reed 43. The end of the middle cross bar 3 is in an L row, and is naturally clamped by the reed 43 after being inserted into the connecting cylinder 42.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com