Preparation method of superfine polytetrafluoroethylene fiber

A polytetrafluoroethylene and polyvinyl alcohol technology, which is used in fiber processing, spinning solution preparation, textile and papermaking, etc., can solve the problems of inability to produce ultra-fine polytetrafluoroethylene fibers, and achieve high fineness uniformity. , The effect of high temperature and corrosion resistance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

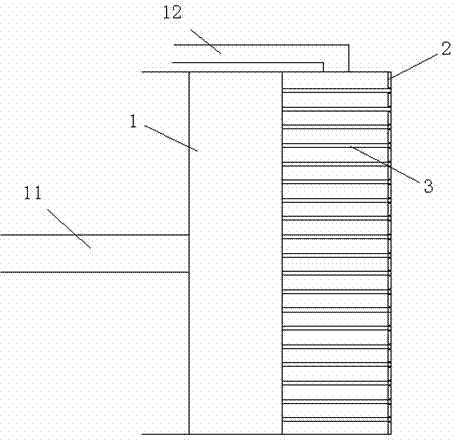

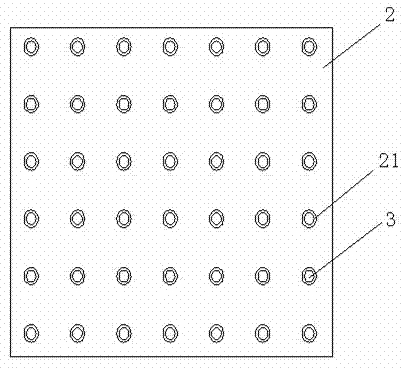

[0027] A preparation method of the ultrafine polytetrafluoroethylene fiber of the present invention, the steps are as follows:

[0028] Preparation of spinning solution 1

[0029] Use polytetrafluoroethylene highly concentrated emulsion, dilute with water to make the viscosity lower than 100cp, add caustic soda to adjust the pH value to 9.

[0030] Preparation of spinning solution 2

[0031] Use polyvinyl alcohol (2488, 1788, etc.) with an alcoholysis degree of 88% to prepare a 15% polyvinyl alcohol solution in cold water, add sulfuric acid to make the pH value at 4, add boric acid at a ratio of 1:100 to facilitate its formation of gel , You can add an appropriate amount of defoamer according to the stirring speed, and the defoamer is simethicone. Static vacuum defoaming for 12 hours for later use.

[0032] Prepare supersaturated coagulation bath

[0033] Dissolve sodium sulfate (glauber's salt) in warm water at 45 degrees Celsius to form a supersaturated solution with cry...

Embodiment 2

[0043] Another kind of preparation method of ultrafine polytetrafluoroethylene fiber, the concrete steps of this method are as follows:

[0044] Preparation of spinning solution 1

[0045] Use polytetrafluoroethylene highly concentrated emulsion, dilute with water to make the viscosity lower than 100cp, add caustic soda to adjust the pH value to 8;

[0046] Preparation of spinning solution 2

[0047] Use alcoholysis degree of 70% polyvinyl alcohol to prepare 10%% polyvinyl alcohol solution in cold water, add sulfuric acid to make the pH value at 3, and add boric acid at a ratio of 1:100, stir to make it form a gel, and then Static vacuum degassing for 10 hours for standby;

[0048] Prepare supersaturated coagulation bath

[0049] Sodium sulfate is dissolved in warm water at 40 degrees Celsius to form a supersaturated solution with crystals, and caustic soda is added to adjust the pH value to 12;

[0050] spinning

[0051] The spinning solution 1 and the spinning solution ...

Embodiment 3

[0058] Another kind of preparation method of ultrafine polytetrafluoroethylene fiber, the concrete steps of this method are as follows:

[0059] Preparation of spinning solution 1

[0060] Use polytetrafluoroethylene highly concentrated emulsion, dilute with water to make the viscosity lower than 100cp, add caustic soda to adjust the pH value to 10;

[0061] Preparation of spinning solution 2

[0062] Prepare a 120% polyvinyl alcohol solution in cold water with polyvinyl alcohol with a degree of alcoholysis of 90%, add sulfuric acid to make the pH value at 5, and add boric acid at a ratio of 1:100, stir to make it form a gel, and then stand still Vacuum degassing for 15 hours for standby;

[0063] Prepare supersaturated coagulation bath

[0064] Sodium sulfate is dissolved in warm water at 50 degrees Celsius to form a supersaturated solution with crystals, and caustic soda is added to adjust the pH value to 14;

[0065] spinning

[0066] Spinning liquid 1 and spinning liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com