Method and device for accelerating powder method boronisation by alternating-current filed

A technology of alternating electric field and powder method, which is applied in the field of chemical heat treatment on the surface of metal parts. It can solve the problems of low utilization rate of boron supply agent, increase the difficulty of cleaning parts after infiltration, and affect the surface quality of parts. Simplicity and the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Material to be infiltrated: 45 steel; composition of boronizing agent: boron donor (iron boron, content 6%), activator and infiltration agent (potassium fluoroborate, 5%), loosening agent (charcoal, 2%), filler and activator (silicon carbide, balance).

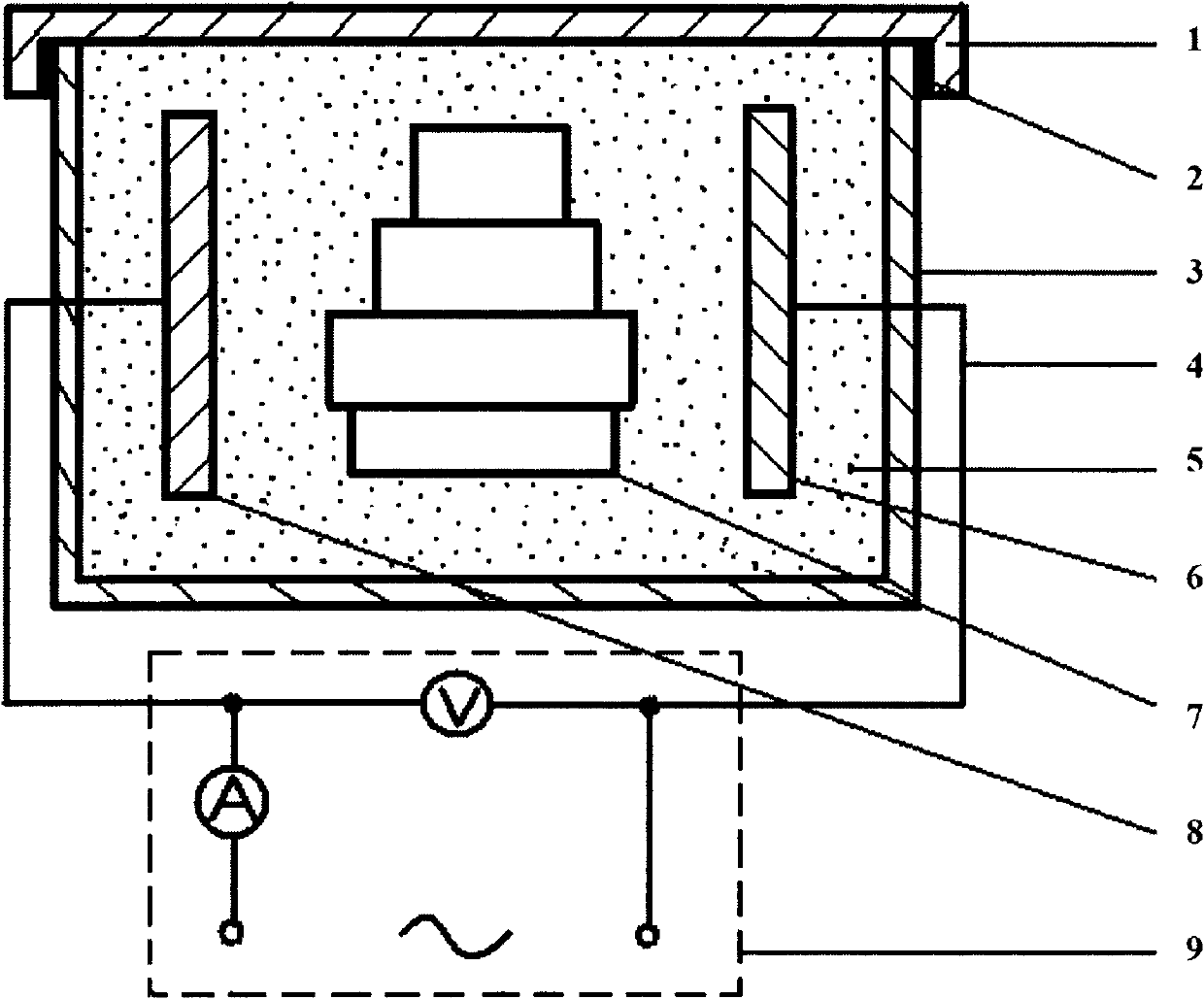

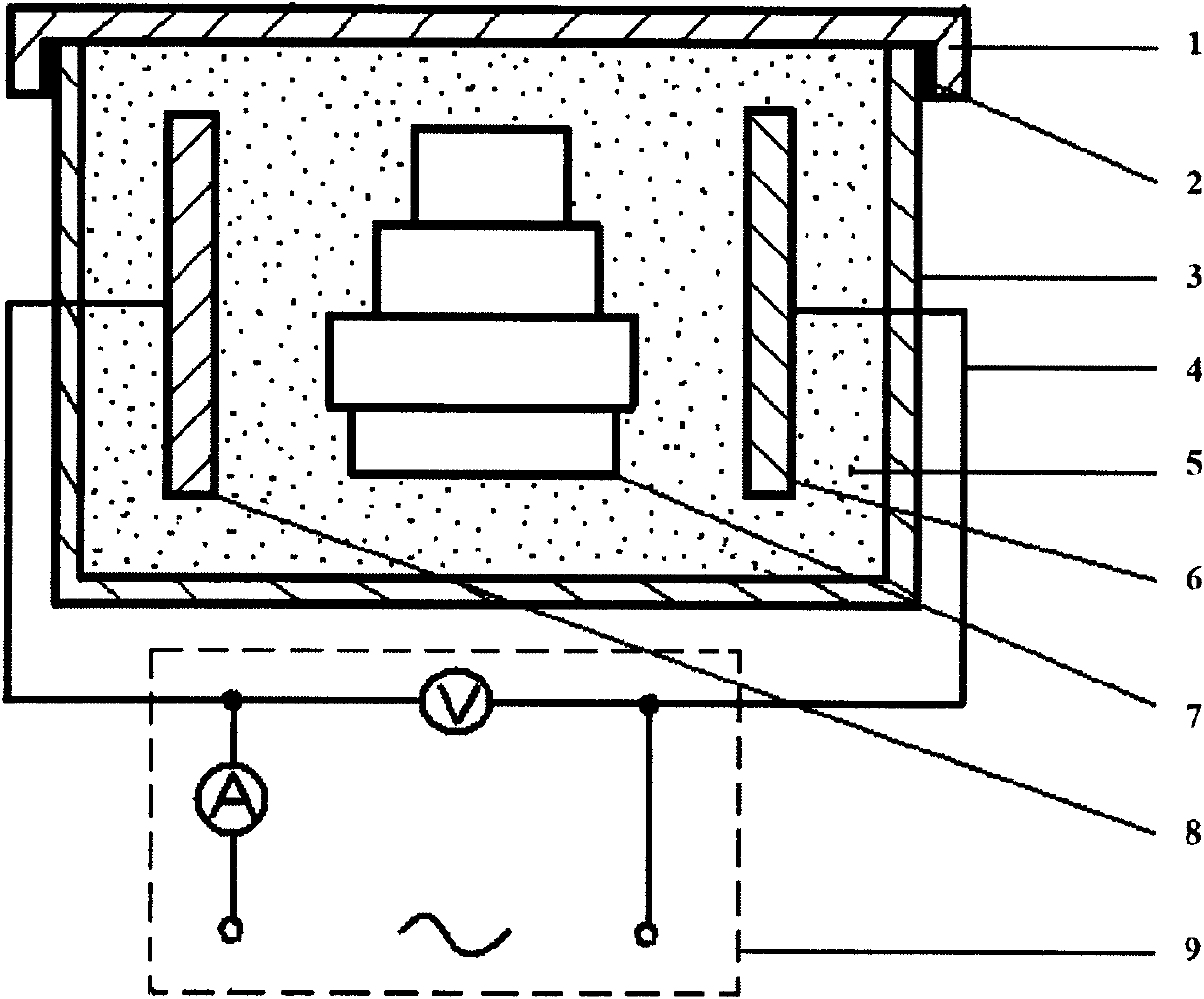

[0019] Place two plate electrodes (6), (8) in parallel in the solid powder boronizing agent (5) composed of the above substances, and the distance between the infiltrated sample (7) and the electrodes (6), (8) on both sides is 15mm , the two electrodes (6), (8) are respectively connected to a 50Hz AC power system (9) whose voltage is continuously adjustable in the range of 0-250 volts by wires (4), and the plate electrodes (6), (8) and The infiltrated sample (7) and the powder boronizing agent (5) are sealed in the infiltration box (3) with the infiltration box cover (1) by the refractory mud sealing material (2), and the infiltration box is placed in the box furnace Heating, boronizing temperature: 800°C, when the fur...

Embodiment 2

[0022] Material to be infiltrated: 20 steel; composition of boronizing agent: boron donor (iron boron, content 3%), activator and infiltration agent (potassium fluoroborate, 5%;), loosening agent (charcoal, 2%), filler agent and activator (silicon carbide, balance).

[0023] The boronizing method and device are the same as in Example 1. The boronizing temperature is 800° C., the boronizing time is 4 hours, the distance between the sample to be infiltrated and the plate electrodes on both sides is 10 mm, and an AC electric field of 30 volts is applied between the plate electrodes. Test results: 20 steel has a boronizing layer of 90μm, and its hardness is 1200-1500HV 0.1 ; while using the same formulation of infiltrating agent, using the existing conventional powder method boronizing process, also after boronizing at 800 ° C for 4 hours, the thickness of the boronizing layer is only 20 μm.

Embodiment 3

[0025] Material to be infiltrated: 45 steel; composition of boronizing agent: boron donor (boron carbide, content 3%), activator and infiltration agent (potassium fluoroborate, 5%; ammonium chloride; 1%), loosening agent (charcoal , 2%), fillers and activators (silicon carbide, the balance).

[0026] The boronizing method and device are the same as in Example 1, the boronizing temperature is 600° C., and the boronizing time is 4 hours. The distance between the infiltrated sample and the plate electrodes on both sides is 10 mm, and an alternating electric field of 50 volts is applied between the plate electrodes and the infiltrated sample. Test results: 45 steel obtained a 30μm boronizing layer with a hardness of 1100-1500HV 0.1 ; while using the same formulation of infiltrating agent, using the existing conventional powder method boronizing process, the same boronizing at 600 ° C for 4 hours, basically no boronizing layer is formed on 45 steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com