Preparation method of medium/low-viscosity high-thixotropy nano calcium carbonate for aqueous system

A nano-calcium carbonate, water-based system technology, used in adhesive additives, non-polymer adhesive additives, dyeing low-molecular-weight organic compounds and other directions, can solve the problems of easy agglomeration, high viscosity, poor compatibility, etc. The effect of small average particle size, high whiteness and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

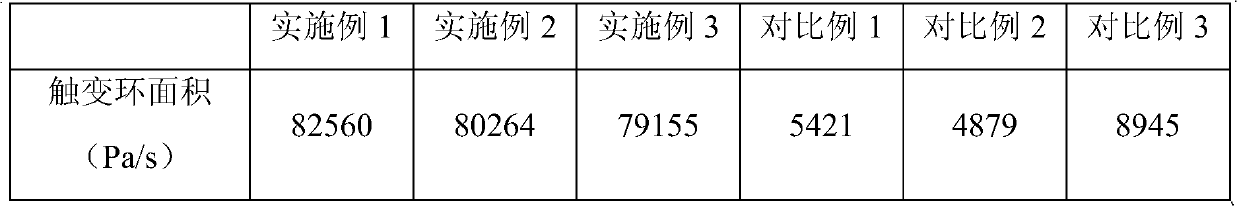

Examples

Embodiment 1

[0021] The calcium carbonate ore is cleaned and calcined at 1000°C. After the product is purified, digested and aged, it is prepared by adding water to prepare a calcium hydroxide slurry with a mass fraction of 10%, which is transferred to the membrane dispersion carbonization reactor, and the relative calcium hydroxide is added 0.5% sucrose by mass of calcium hydroxide in slurry. Introduce a mixture of carbon dioxide and air with a volume fraction of 30% carbon dioxide, and use the bubbling method for carbonization synthesis at 17°C. When the pH drops to 6.8, continue to ventilate for 10 minutes to obtain nano-calcium carbonate slurry. Select every 100ml slurry The nano-calcium carbonate slurry with an apparent sedimentation volume of 85-99ml in three hours. Add water to adjust the concentration of nano-calcium carbonate slurry to 10%, take 1000g, heat up to 80°C and stir for 10 minutes, add 2.5g of sodium dodecylbenzenesulfonate, and stir for 1 hour. Weigh 2g of stearic aci...

Embodiment 2

[0023] The calcium carbonate ore is cleaned and calcined at 1000°C. After the product is purified, digested and aged, it is prepared by adding water to prepare a calcium hydroxide slurry with a mass fraction of 10%, which is transferred to the membrane dispersion carbonization reactor, and the relative calcium hydroxide is added 0.5% sucrose by mass of calcium hydroxide in slurry. Introduce a mixture of carbon dioxide and air with a carbon dioxide volume fraction of 30%, and carry out carbonization synthesis at 17°C using the supergravity method. When the pH drops to 6.8, continue to ventilate for 10 minutes to obtain nano-calcium carbonate slurry. Select every 100ml slurry The nano-calcium carbonate slurry with an apparent sedimentation volume of 85-99ml in three hours. Add water to adjust the concentration of nano-calcium carbonate slurry to 10%, take 1000g, heat up to 80°C and stir for 10 minutes, add 1g of ammonium citrate and 1g of sodium hexametaphosphate, and stir for 1...

Embodiment 3

[0025] The calcium carbonate ore is cleaned and calcined at 1000°C. After the product is purified, digested and aged, it is prepared by adding water to prepare a calcium hydroxide slurry with a mass fraction of 10%, which is transferred to the membrane dispersion carbonization reactor, and the relative calcium hydroxide is added 0.5% sucrose by mass of calcium hydroxide in slurry. Introduce a mixture of carbon dioxide and air with a carbon dioxide volume fraction of 30%, and use the membrane dispersion method for carbonization synthesis at 17°C. When the pH drops to 6.8, continue to ventilate for 10 minutes to obtain nano-calcium carbonate slurry. Select every 100ml slurry The nano-calcium carbonate slurry with an apparent sedimentation volume of 85-99ml in three hours. Add water to adjust the concentration of nano-calcium carbonate slurry to 10%, take 1000g, heat up to 80°C and stir for 10 minutes, add 3g of sodium polyacrylate, and stir for 1 hour. Weigh 2g of sodium steara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com