Preparation method of urea formaldehyde resin rubber powder

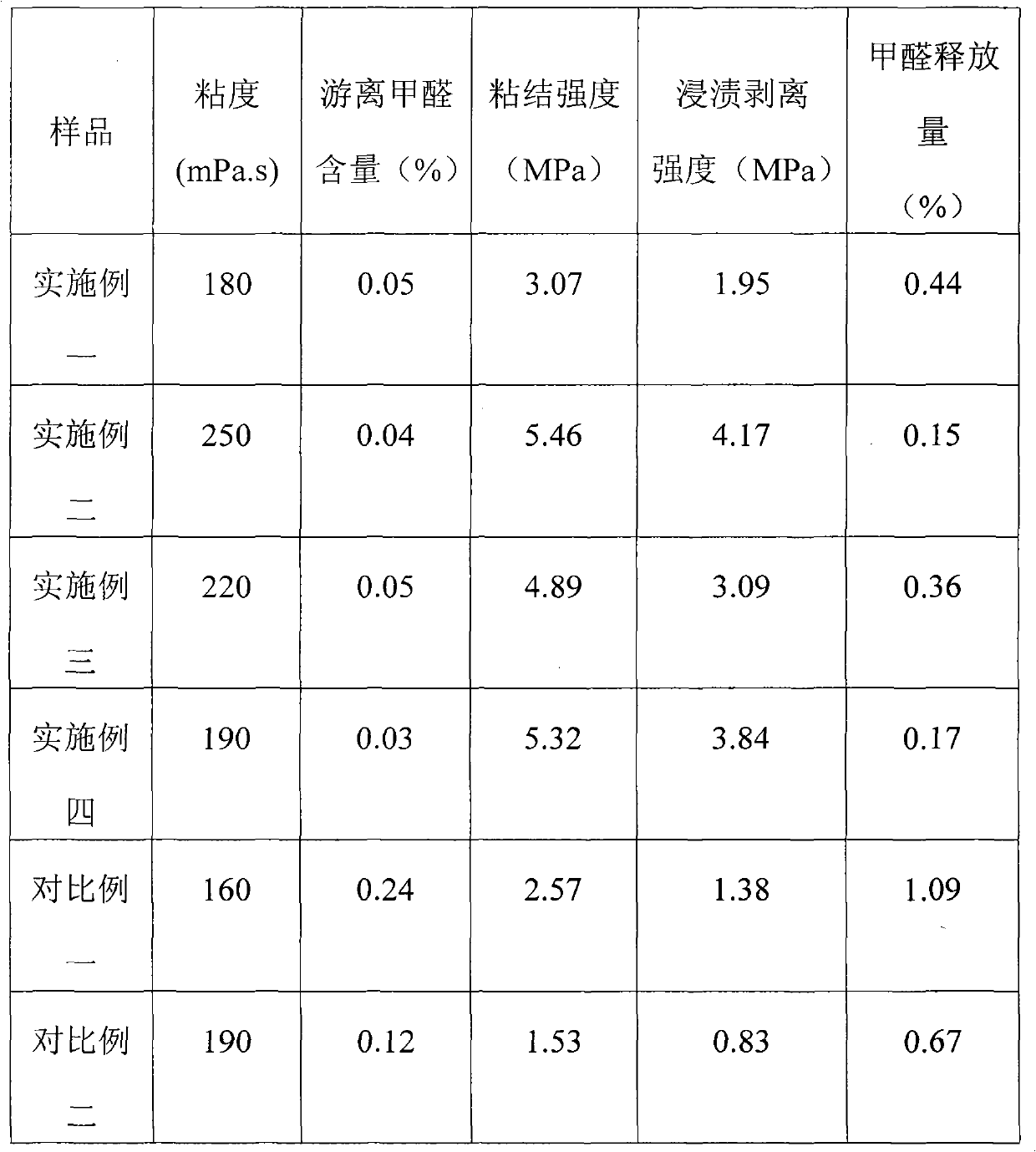

A technology of urea-formaldehyde resin glue and urea-formaldehyde resin, which is applied in the directions of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the deterioration of adhesive bonding strength, water resistance and aging resistance. , poor quality of wood products, etc., to achieve the effect of reducing the amount of free formaldehyde, improving the impregnation peel strength, and reducing the amount of formaldehyde released.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method also includes the following auxiliary agents: protective colloid, inorganic anti-coagulation agent and defoamer.

[0036] Described protective colloid is alcoholysis degree more than 90%, polyvinyl alcohol (PVA) that polymerization degree is 300~1200; Before use, polyvinyl alcohol is formulated into 20% aqueous solution, and the consumption (weight) of polyvinyl alcohol is controlled 4-10% of the total amount (weight) of the urea-formaldehyde resin polymer.

[0037] Inorganic anti-coagulation agent of the present invention comprises wherein a kind of in calcium carbonate, clay, silicon dioxide, aluminum silicate, talcum powder or kaolin, consumption (weight) is 5% in urea-formaldehyde resin polymer total amount (weight) ~20%.

Embodiment 1

[0041] Add 145.95 grams of formalin in a three-necked flask with a reflux condenser, then the reactor is warmed up to 60°C, and the pH value is adjusted to 2.0 with 10% HCl aqueous solution, and 42 grams of urea is added, and the temperature is continued until the reaction temperature reaches At 90°C, react for about 20 minutes; when the reaction becomes turbid, immediately cool down to 75°C and adjust the pH value to 8.5, add 12 grams of urea, and react for 30 minutes; then use NH 4 Adjust the pH value of Cl aqueous solution to 5.5 and react for 30 minutes; adjust the pH value to 8.0 again, add the remaining 6 grams of urea to the reactant, react for 30 minutes, cool the product to room temperature, and discharge it for later use.

Embodiment 2

[0043] Add 145.95 grams of formalin to a three-necked flask with a reflux condenser, then the reactor is warmed up to 60°C, and the pH value is adjusted to 2.0 with 10% formic acid aqueous solution, and 42 grams of urea is added, and the temperature is continued until the reaction temperature reaches At 90°C, react for about 20 minutes; when the reaction becomes turbid, immediately cool down to 80°C and adjust the pH value to 8.5, add 12 grams of urea and 3 grams of melamine, and react for 30 minutes; then use NH 4 Cl aqueous solution adjusts the pH value to 5.5, and reacts for 30 minutes; adjusts the pH value to 8.0 again, adds the remaining 6 grams of urea and 2.7 grams of tripolyhydroamine to the reactant, reacts for 30 minutes, and cools the product to room temperature. spare.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com