Method for preparing fluorine modified zinc acrylate antifouling resin

A technology of zinc acrylate and antifouling resin, applied in antifouling/underwater coatings, paints containing biocide, etc., can solve the problems of poor substrate adhesion, low surface free energy, etc., and achieve easy control of reaction parameters , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] Example 1

[0019] The preparation method of the fluorine-modified zinc acrylic antifouling resin of this embodiment includes the following process steps:

[0020] 1. Add 80g of propylene glycol methyl ether, 49.5g of zinc hydroxide into a four-necked flask equipped with a stirrer, reflux condenser, constant pressure dropping funnel, and thermometer, stir and heat to 80°C, and weigh 36g acrylic acid and 61g benzene. The mixture of formic acid and 130 g of propylene glycol methyl ether was dropped through a constant pressure dropping funnel for 2 hours at a constant rate, and stirring was continued for 1 hour to obtain a transparent and colorless solution of zinc-containing acrylic acid small molecule monomer.

[0021] The solid content of the colorless and transparent solution was measured to be 41%.

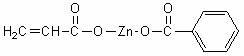

[0022] The structural formula of the prepared zinc-containing small molecule monomer can be expressed as follows:

[0023]

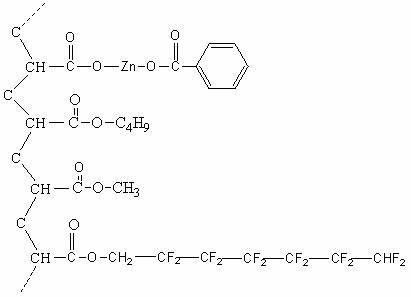

[0024] 2. Then add 30g of propylene glycol methyl e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com