Anti-rotation self-locking semitrailer for bottle type high-pressure containers

A high-pressure container, semi-trailer technology, applied in the direction of tractor-trailer combination, motor vehicle, bottled transportation, etc., can solve the problems of safety accidents, easy to cause safety accidents, difficult container rotation and vibration, etc., to prevent rotation and vibration. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following further description with reference to the drawings does not limit the scope of the present invention.

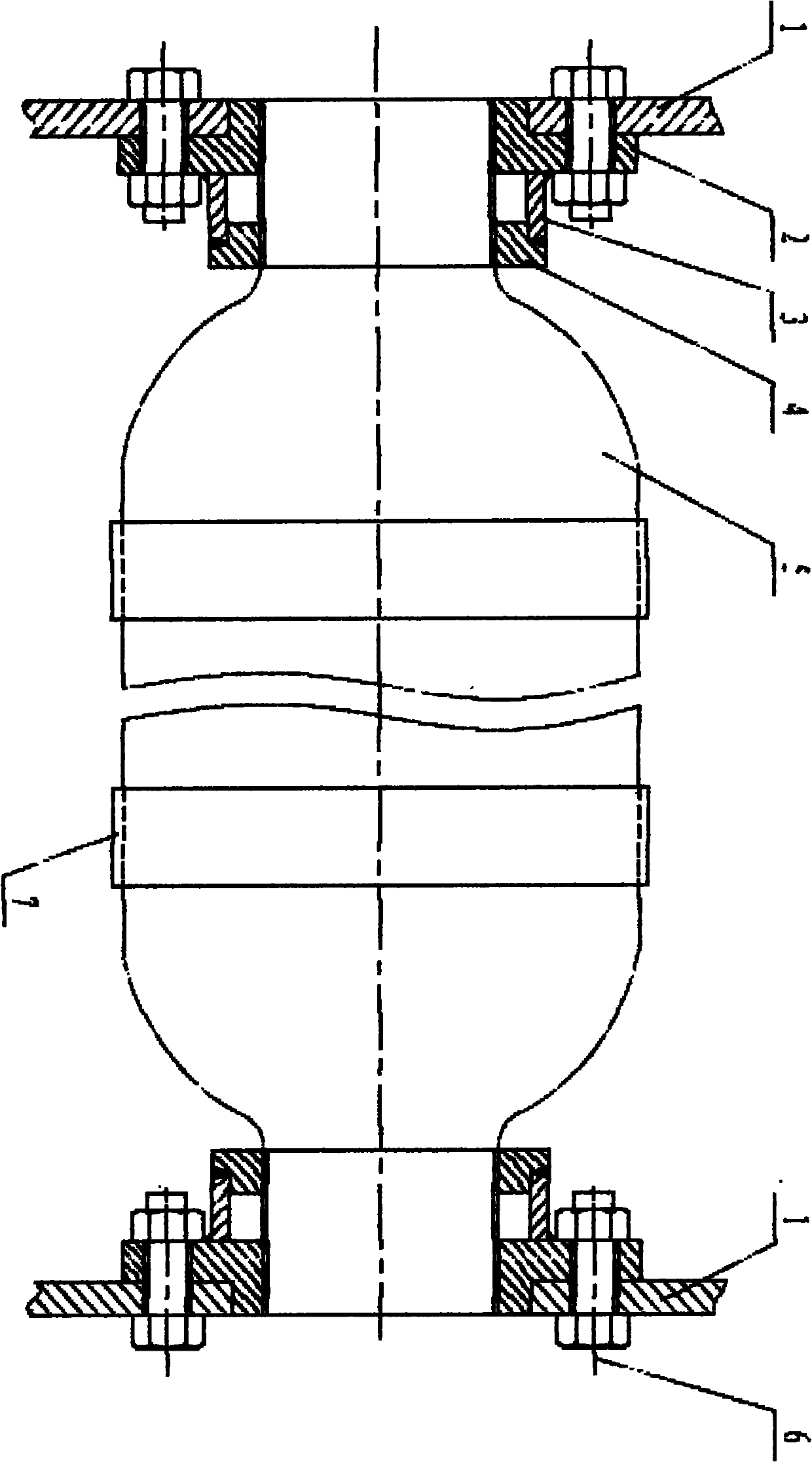

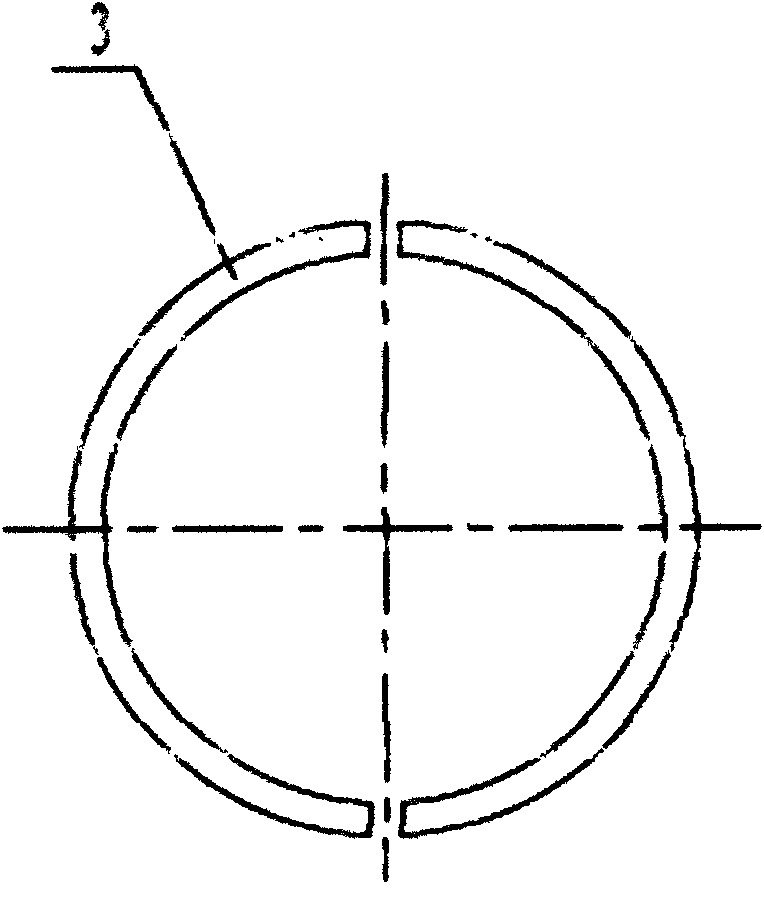

[0029] See Figure 1 to Figure 11 As shown, the present invention includes a fixed steel plate 1, a bottle flange 2, a fixed sleeve 3, a spare cap 4, a bottle container 5, a bolt 6, a fixed interlocking device 7, a cable tie 8, a rubber plate 9, a compression nut 10, The stud 11, the spacer 12, the shock-absorbing anti-rotation plug 13, the touch-type parking brake valve 14, the operating box door 15, the operating box 16, the frame 17 and the parking pillar 18.

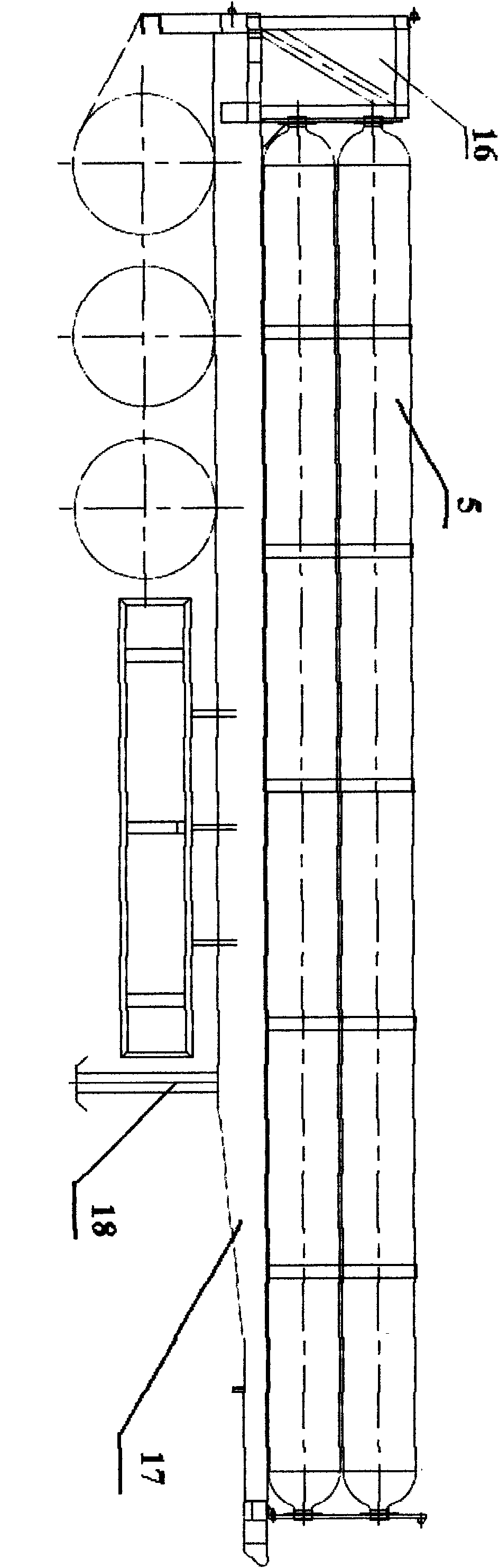

[0030] Such as figure 1 As shown, the present invention is provided with an operating box 16, a vehicle frame 17, and a parking pillar 18. When the tractor is stopped, the parking pillar 18 is extended for support, and a bottle container 5 is provided on the vehicle frame 17.

[0031] Such as figure 2 As shown, when assembling, first install the spare cap 4 on the threaded openings at both ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com