Heat-storing catalytic composite functional material and preparation method thereof

A composite function, heat storage technology, applied in heat exchange materials, chemical instruments and methods, catalyst carriers, etc., to solve the effect of uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

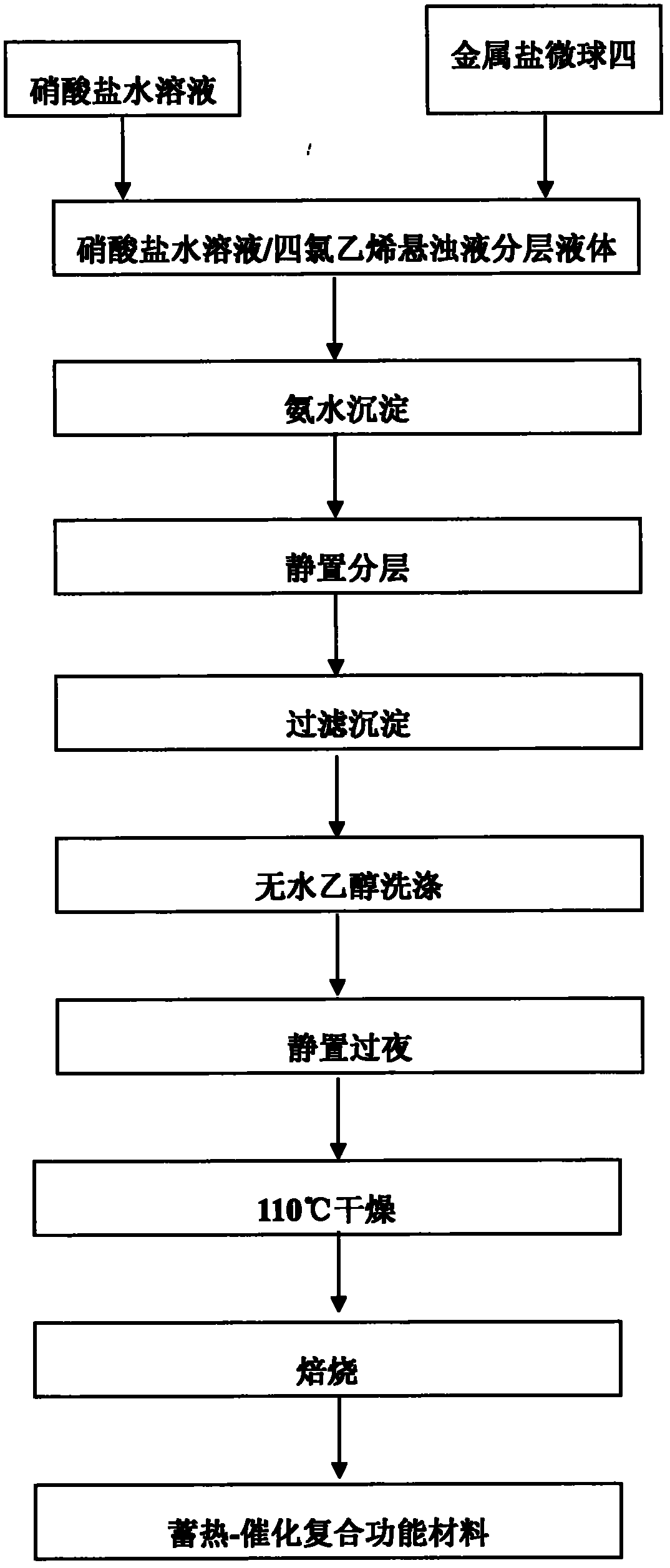

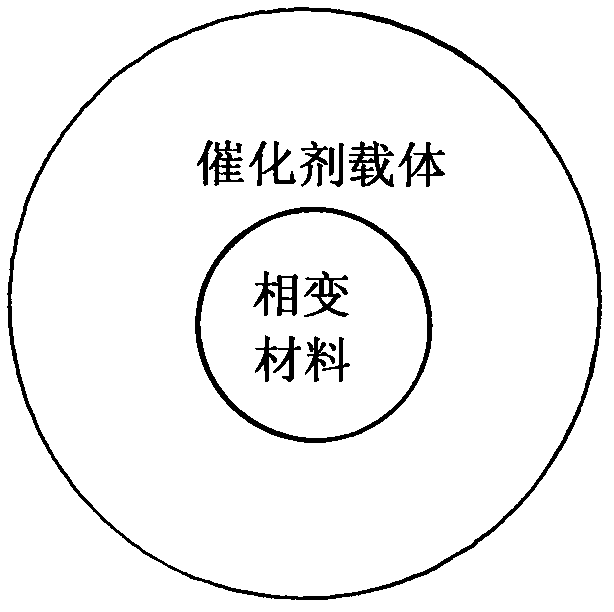

[0021] The preparation process of the heat storage-catalysis composite functional material of the present invention is as follows: the metal salt microspheres prepared in advance are dispersed in silicone oil (C 2 Cl 4 , insoluble in water and denser than water), and form a suspension under the action of a magnetic stirrer. Configure a certain concentration of nitrate solution (aluminum nitrate, titanium nitrate, magnesium nitrate or zirconium nitrate, etc.), and join it in the above-mentioned tetrachlorethylene suspension (the volume ratio of aqueous solution and tetrachlorethylene suspension is 1: 1), let it stand for 10-30 minutes to make the layered liquid level clearly visible. The upper aqueous solution is stirred counterclockwise at a constant speed with an electric stirrer, and the lower layer of tetrachlorethylene suspension is stirred clockwise with a magnetic stirrer. After being stable for 2-10 minutes, drop ammonia solution to precipitate the upper layer of nitra...

Embodiment 1

[0025] 1) Implementation conditions

[0026] 0.1 μm Li 2 CO 3 Microspheres and tetrachlorethylene are configured to form a 10g / L suspension, and 0.2mol / L aluminum nitrate solution is added to form a layered solution. Al 2 o 3 / Li 2 CO 3 Composite functional materials. This material is used as a catalyst carrier in the partial oxidation of methane process, loaded with 10% Ni catalyst, with high-purity methane containing helium (used as diluent gas) and oxygen [V(CH 4 ): V(O 2 ):V(He)=40:20:40) as the raw material gas, the reaction temperature is 800°C, and the reaction space velocity is 6000mL·g -1 h -1 .

[0027] 2) Implementation results

[0028] The sintered strength of the finished product is higher. The particle size range of the obtained composite material is 2-10μm, the thermal expansion coefficient is 0.35, and the sintered density is 2.23g / cm 3 , the porosity is 14-23%, the thermal conductivity is 35.8w / m·k, and the heat storage density at 700-750℃ is 960....

Embodiment 2

[0030] 1) Implementation conditions

[0031] 10μm NaCl microspheres and tetrachlorethylene are configured to form a 50g / L suspension, and 1mol / L titanium nitrate solution is added to form a layered solution. Precipitate with ammonia water, stand still, filter, and roast in air atmosphere at 800°C for 8 hours to obtain TiO 2 / NaCl composite functional material. The material was used as a catalyst carrier for methane catalytic combustion, loaded with 15% Fe 2 o 3 Catalyst, with N 2 (used as diluent) of high-purity methane and oxygen [V(CH 4 ): V(O 2 ): V(N 2 )=10:40:50) mixed gas as raw material gas, the reaction temperature is 300-800°C, and the reaction space velocity is 1200mL·g -1 h -1 .

[0032] 2) Implementation results

[0033] The sintered strength of the finished product is higher. The particle size range of the obtained composite material is 21-78μm, the thermal expansion coefficient is 0.31, and the sintered density is 2.56g / cm 3, the porosity is 12-17%, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heat storage density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com