Electrostatic composite metal-filler wet-type dust removing and filtering device and filtering method

A metal filler, wet dust removal technology, applied in separation methods, electrostatic effect separation, chemical instruments and methods, etc., can solve the problems of secondary air pollution, easy reproduction of bacteria, low filtration efficiency, etc., to avoid secondary pollution, ensure Human health, overcoming the effect of low filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

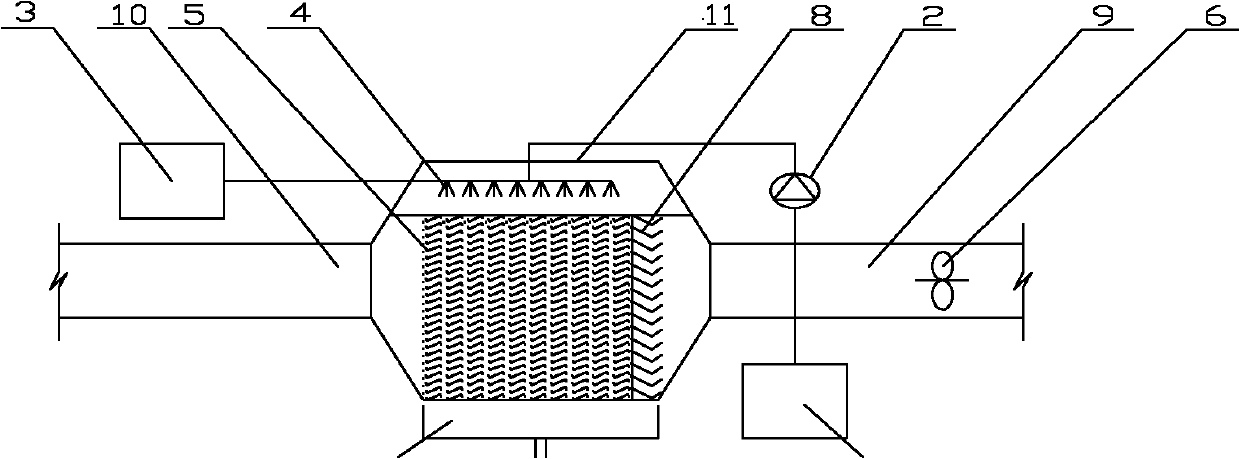

[0011] Electrostatic composite metal filler wet dust removal filter device, including: water storage tank 1, water pump 2, rectification step-up transformer 3, high-voltage metal nozzle group 4, metal corrugated packing 5, fan 6, water storage tank 7 and water retaining plate 8, its structure is as follows figure 1 As shown, the upper part of the dust removal filter 11 has a built-in high-pressure metal nozzle group 4, and the water inlet of the high-pressure metal nozzle group 4 is externally connected to a water pipe, and the water pipe is connected to the water storage tank 1 through a water pump 2; The air outlet position of 5 is equipped with a water baffle 8, the bottom of the dust removal filter 11 is connected to the water storage tank 7, one end of the dust removal filter 11 is connected to the air inlet pipe 10, and the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com