Preparation method of soluble rice protein

A rice protein, soluble technology, applied in the direction of plant protein processing, etc., can solve the problems of high cost, limited popularization and application, and strict implementation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

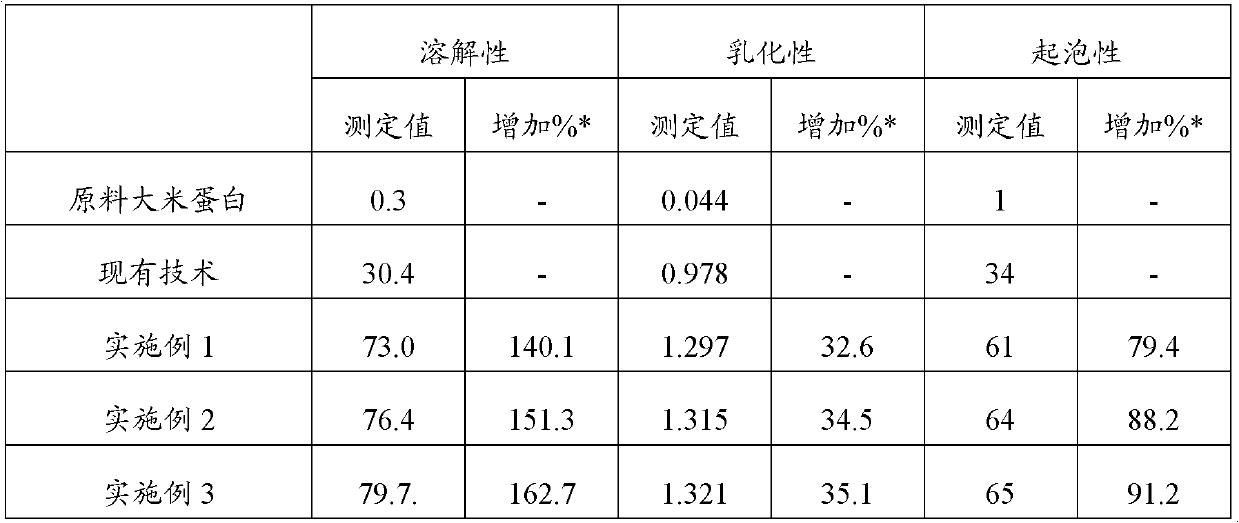

Examples

Embodiment 1

[0098] Example 1: The preparation method of soluble rice protein of the present invention

[0099] The steps of this method are as follows:

[0100] (1) Mixing

[0101] According to the weight ratio of water and rice protein of 1:6, 1 kg of rice protein with a protein content of 80% and 6 kg of water are uniformly stirred and mixed to obtain a feed liquid.

[0102] (2) Crushing

[0103] The feed liquid obtained in step (1) is pulverized by micro-jet until the protein particle size is ≤10 μm, wherein the pressure of the micro-jet is 25000 psi, and the flow rate is 400 ml / min.

[0104] (3) Deamidation

[0105] In the solution that step (2) obtains, add concentration to be 37% Concentrated hydrochloric acid, so that the concentration of hydrochloric acid in the solution is 0.1mol / L, and the solution is reacted with concentrated hydrochloric acid at 85°C for 6h.

[0106] (4) Chelation

[0107] Add 0.5% sodium tripolyphosphate based on the protein amount to the reaction solu...

Embodiment 2

[0115] Example 2: The preparation method of soluble rice protein of the present invention

[0116] The steps of this method are as follows:

[0117] (1) Mixing

[0118] According to the water to rice protein weight ratio of 1:7, the protein content of 70% 1 kg rice protein vs. 7 kg of water was stirred and mixed uniformly to obtain a feed liquid.

[0119] (2) Crushing

[0120] The feed liquid obtained in step (1) is pulverized by micro-jet until the protein particle size is ≤10 μm, wherein the pressure of the micro-jet is 25000 psi, and the flow rate is 400 ml / min.

[0121] (3) Deamidation

[0122] In the solution that step (2) obtains, add concentration to be 37% Concentrated hydrochloric acid, so that the concentration of hydrochloric acid in the solution is 0.1mol / L, and the solution is reacted with concentrated hydrochloric acid at 83°C for 7 hours.

[0123] (4) Chelation

[0124] Add 1% sodium tripolyphosphate based on the protein amount to the reaction solution...

Embodiment 3

[0132] Example 3: The preparation method of soluble rice protein of the present invention

[0133] The steps of this method are as follows:

[0134] (1) Mixing

[0135] According to the water to rice protein weight ratio of 1:8, the protein content of 90% 1 kg rice protein vs. 8 kg of water was stirred and mixed uniformly to obtain a feed liquid.

[0136] (2) Crushing

[0137] The feed liquid obtained in step (1) is pulverized by micro-jet until the protein particle size is ≤10 μm, wherein the pressure of the micro-jet is 25000 psi, and the flow rate is 400 ml / min.

[0138] (3) Deamidation

[0139] In the solution that step (2) obtains, add concentration to be 37% Concentrated hydrochloric acid, so that the concentration of hydrochloric acid in the solution is 0.1mol / L, and the solution is reacted with concentrated hydrochloric acid at 80°C for 5 hours.

[0140] (4) Chelation

[0141] Add 1.5% sodium tripolyphosphate based on the protein amount to the reaction soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com