Environmentally-friendly, Pb-free free-machining steel, and manufacturing method for same

A rapid cutting and steel ingot technology, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of not providing MnS, etc., achieve excellent machinability, excellent hot rolling ability, and improve machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] In this embodiment, steel ingots having the compositions of Experimental Examples and Comparative Examples (SUM24L) in Table 1 below were prepared on the order of 200 kg in a high-frequency induction melting furnace. Here, the comparative example is the most widely used lead (Pb) free-cutting steel at present, that is, SUM24L. The steel ingots of the experimental example and the comparative example were prepared by the same experimental device and preparation method, and the size of the steel ingot prepared at this time was 230mm×230mm×350mm.

[0109] [Table 1]

[0110]

C

Si

mn

P

S

N(ppm)

other ingredients

Experimental example 1

0.09

0.01

1.0

0.08

0.25

98

Cr 0.4, Ti 0.2

Experimental example 2

0.08

0.02

1.1

0.08

0.30

78

Cr 0.1, Ti 0.02

Experimental example 3

0.08

0.03

1.2

0.08

0.30

83

Cr 0....

Embodiment 2

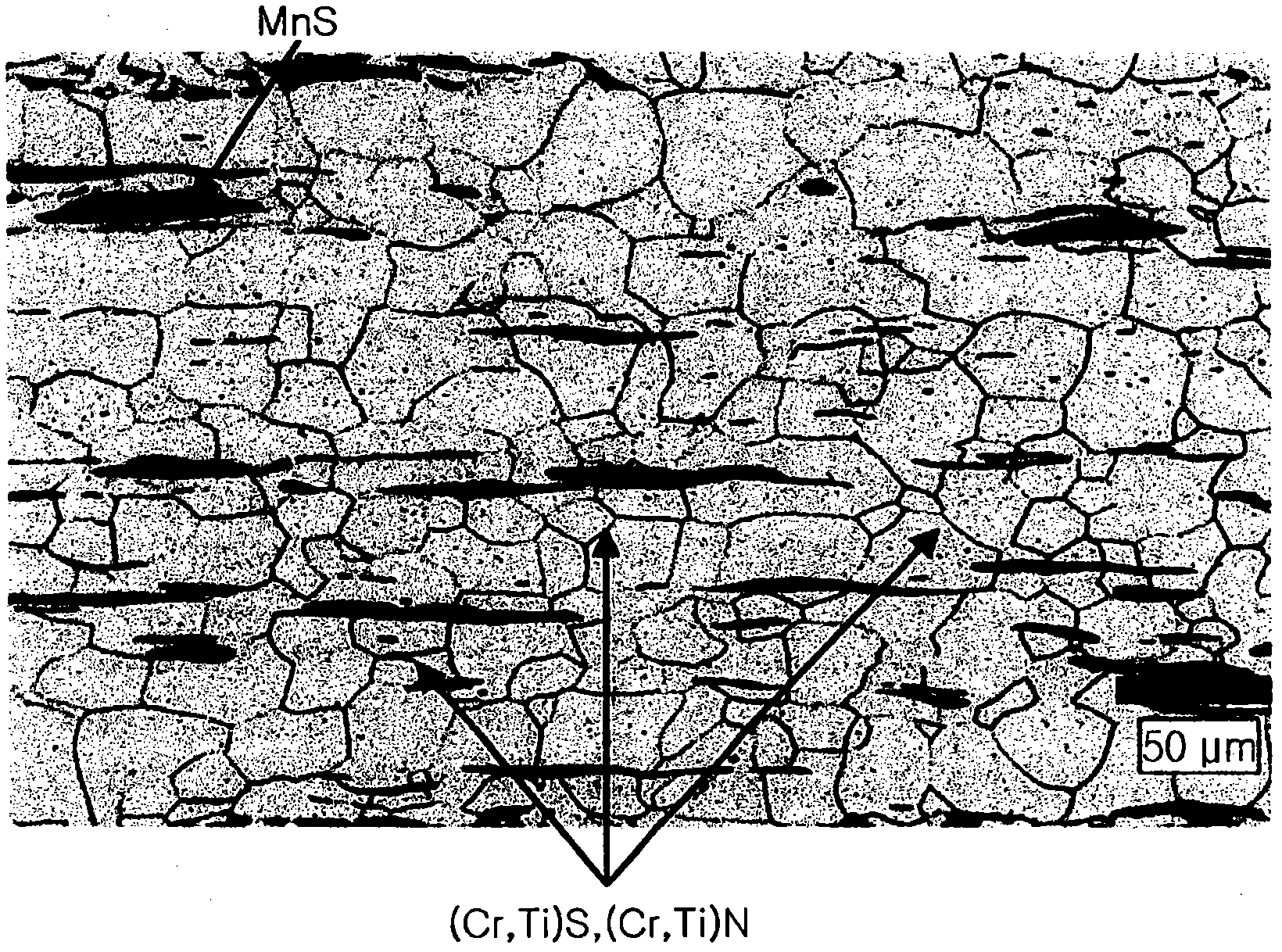

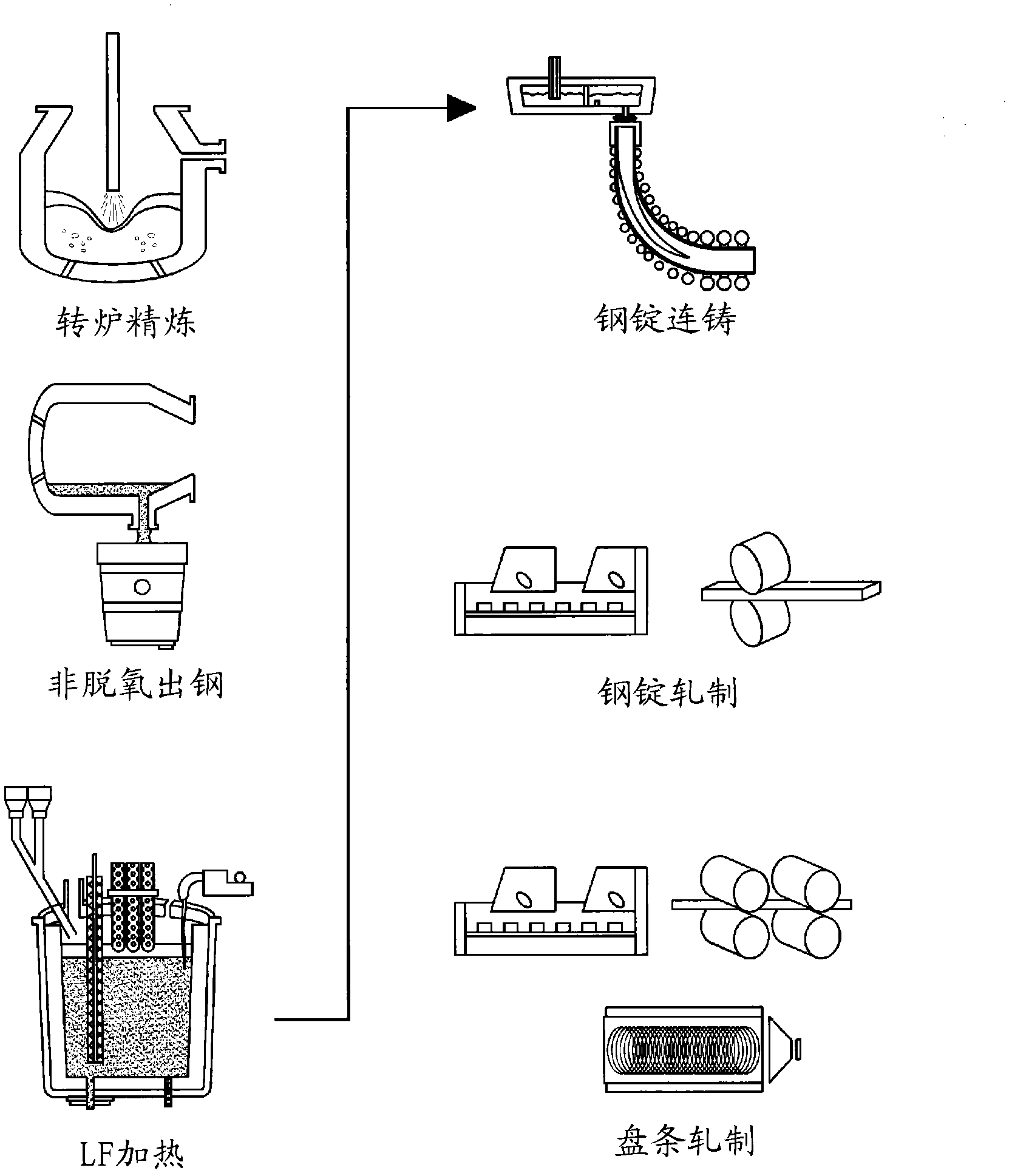

[0115] In the ingot rolling method, a free-cutting steel ingot with a size of 300mm×400mm after complete continuous casting is rolled into a billet with a size of 160mm×160mm, and subsequently, the billet is rolled into a diameter of 25mm in the wire rod rolling process of wire rod. At this time, the ingot and billet are heated and cooled by the usual free-cutting steel rolling conditions. Samples were collected from the wire rod after rolling, the total oxygen content was measured by a N / O analyzer, and the area and shape of MnS were observed by an optical microscope. Meanwhile, after completion of the wire rod rolling, the wire rod (Wire Rod) was cold drawn to prepare a cold drawn rod (CD Bar) with a diameter of 23 mm, after which the tool life was measured under the same conditions after cutting experiments using a CNC machine tool. The following table 2 shows the total oxygen content (ppm) of the wire rod obtained by the above experiment, with an area of 5 μm 2 per mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com