Lingnocellulosic products and methods of forming the same

一种木质纤维、产品的技术,应用在制造工具、扁平制品、其他家里用具等方向,能够解决制备成本增加等问题,达到降低制备成本、降低溶胀性、出色防潮性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Other graft polyols suitable for the purposes of the present invention and methods for their preparation include those described in the following U.S. Patents: 4,522,976 to Grace et al; 5,093,412 to Mente et al; 5,179,131 to Wujcik et al; 5,594,066 of Kratz et al. 5,814,699 of Kratz et al. 6,034,146 of Falke et al. 6,103,140 of Falke et al. 6,352,658 of Chang et al. 6,432,543 of Harrison et al. 7,179,882, the disclosure of which is incorporated herein by reference in its entirety.

[0043] Specific examples of graft polyols suitable for the purposes of the present invention are available under the trademark PLURACOL Commercially available from BASF Corporation of Florham Park, NJ as PLURACOL 1365. PLURACOL 4600、PLURACOL 4650、PLURACOL 4800、PLURACOL 4815、PLURACOL 4830 and PLURACOL 4850 grafted polyol. It will be appreciated that the processing aid may comprise any combination of the graft polyols described above. Detailed information on graft polyo...

Embodiment

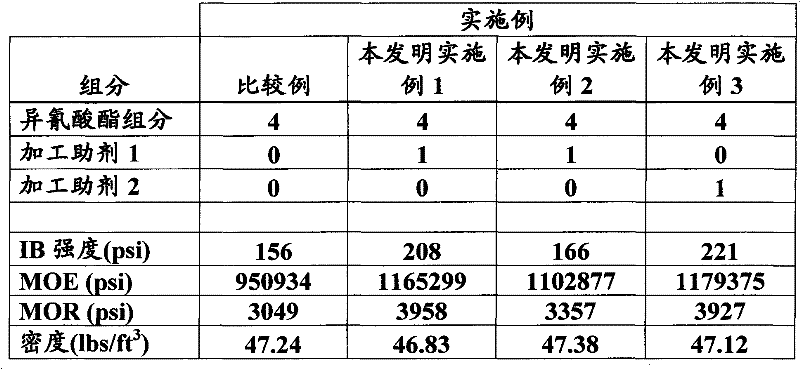

[0076]Examples of producing wood fiber composite products, specifically, one comparative example (comparative example) and three examples of the invention (invention examples 1 to 3) were prepared. The lignocellulosic composite article formed below is particle board. The examples were prepared using a preparation method normally used for the preparation of particle board (PB) such that the preparation method did not impart a difference to the examples. The amounts and types of the various components used to form the lignocellulosic products are indicated in Table I below, with all values in parts by weight based on 100 parts by weight of all components.

[0077] Table I

[0078]

[0079] The isocyanate component was polymeric MDI having a functionality of about 2.7, an NCO content of about 31.5 wt%, and a viscosity of about 200 cps at 25°C, commercially available from BASF Corporation of Florham Park, NJ.

[0080] Processing Aid 1 is a secondary hydroxyl terminated graf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com