Method and device for applying methane to industrial hating furnace

An application method and heating furnace technology, applied in the field of biogas application, can solve the problem that biogas cannot be applied to industrial heating furnaces, etc., and achieve the effects of ensuring roasting temperature requirements, saving energy, and reducing dust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

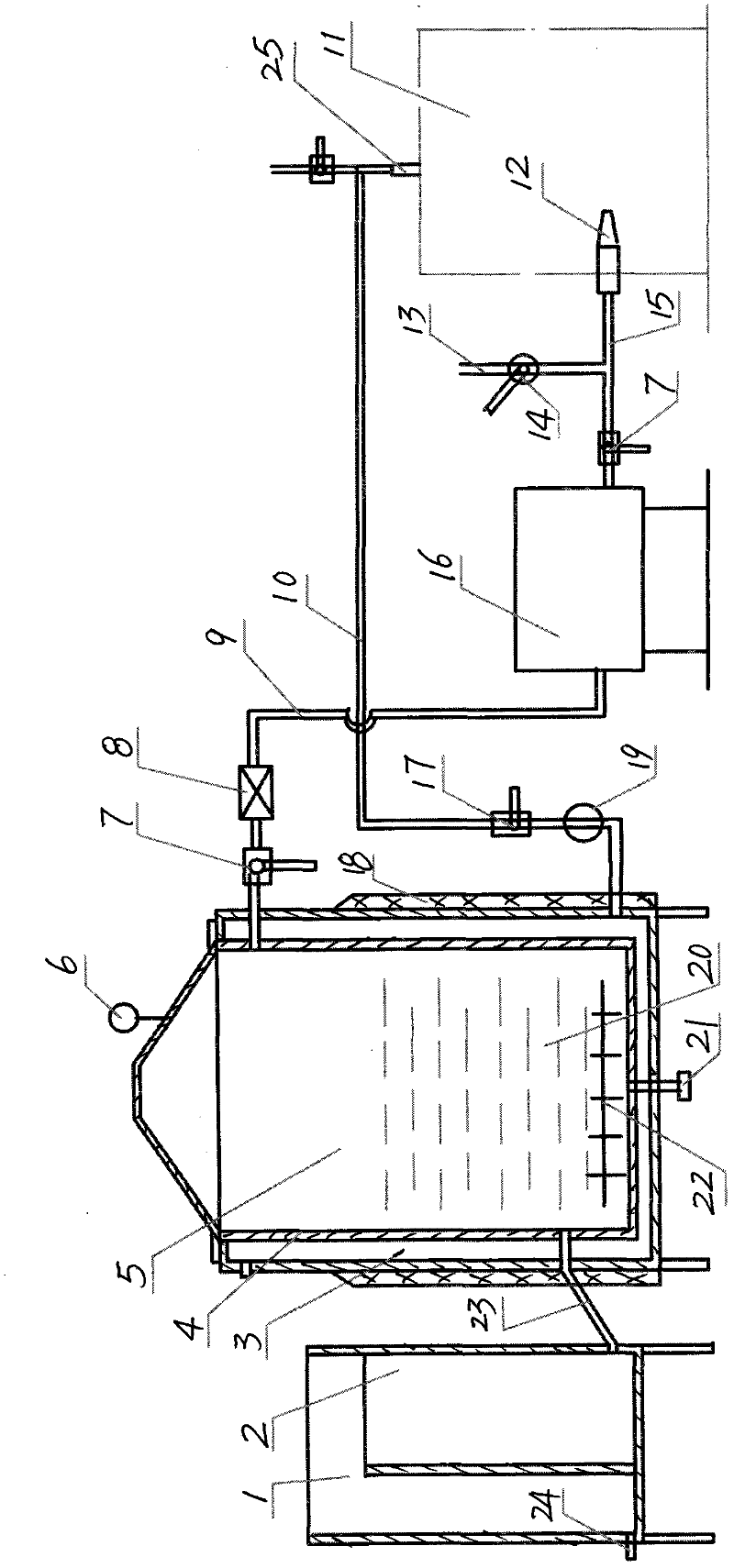

[0021] Example 1, in figure 1 Among them, the biogas device in the industrial heating furnace according to the present invention includes a biogas digester 4, a heating chamber 3 located outside the biogas digester, the upper part of the biogas digester is biogas 5, and the lower part is fermentation material 20. Between the biogas digester and the bucket 2 Connected with a drain pipe 23, an outer bucket 1 is arranged on the outside of the bucket, the outer bucket is higher than the bucket, a drain valve 24 is installed on the outer bucket, a pressure gauge 6 is set on the top of the biogas tank, and a Cleaning valve 21, the cleaning valve is used for cleaning and clearing the biogas digester, the heating chamber is an annular cavity surrounding the sides and bottom of the biogas digester, and an insulation layer 18 is preferably arranged on the outside of the heating chamber, and the bottom of the biogas digester is preferably A mixer 22 is provided, a delivery pipe 9 is conn...

Embodiment 2

[0023] Embodiment 2, biogas is used for firing ceramic building materials (such as magnetic plates, tiles, etc.) 3 , under the heating condition of 55-60 ℃, the daily biogas production can be at least 3000m3 3 , build a capacity of 1500m 3 The gas storage, the volume of the prismatic kiln is 36m 3 , based on the maximum annual output of ceramic products of 10,000 tons, and the daily output of ceramic products per furnace is 40 tons. The actual working days of the rib-type kiln are 250 days a year, and the amount of biogas required per cubic meter per day for each shuttle kiln is 75m 3 Calculated, the maximum amount of biogas consumed per day is 36×75=2700m 3 , the annual gas consumption is 250×2700=675,000 cubic meters, the maximum daily consumption of biogas is less than the minimum daily production of biogas, therefore, the biogas tank capacity is 2000m 3 , under the heating condition of 55-60 ℃, the biogas production capacity can fully meet the volume of 36m 3 , with an...

Embodiment 3

[0024] Embodiment 3, the application method and application device of the biogas in the industrial heating furnace according to the present invention can also be used for boiler heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com