Special anti-aging modified master batch for polyethylene tubes

A polyethylene pipe, anti-aging technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve problems such as difficulty in adding, and achieve the effect of improving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

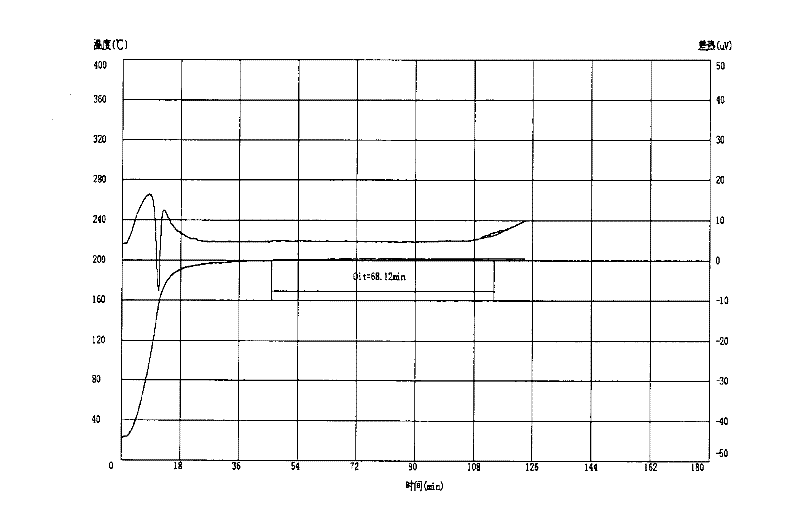

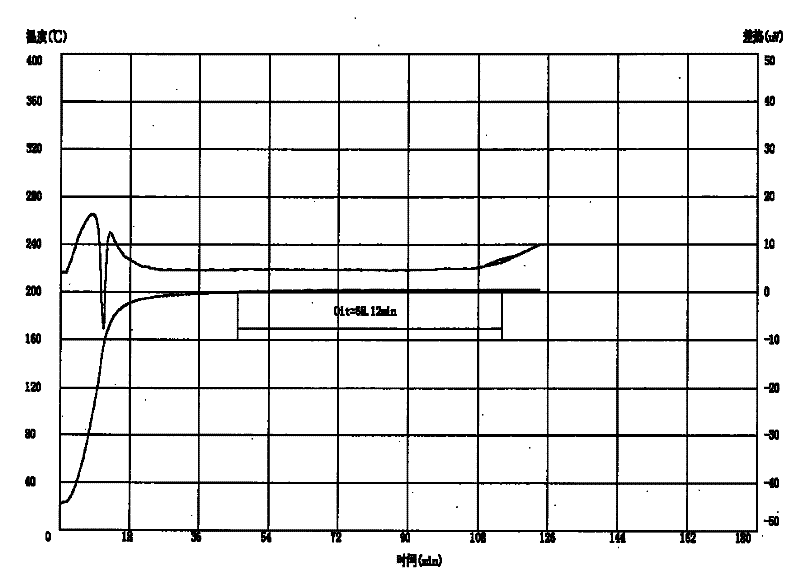

Image

Examples

Embodiment

[0018] Embodiment: A special anti-aging modified masterbatch for polyethylene pipes. The raw material components include the following by weight percentage: 20% HDPE, 50% LLDPE, 25% antioxidant, 2% polyethylene wax, and 3% white oil.

[0019] HDPE is high-density polyethylene, tensile strength ≥ 20Mpa, elongation at break ≥ 400%, Vicat softening point ≥ 100 ℃, melt flow rate 0.1g / 10min or more; LLDPE is low-density linear polyethylene, tensile Tensile strength≥9Mpa, elongation at break≥500%, Vicat softening point≥95℃, melt flow rate above 2g / 10min; antioxidant is tetrakis[β-(3,5-di-tert-butyl-4- Hydroxyphenyl) propionic acid] pentaerythritol ester, molecular weight 1000-1500 and tris (2.4-di-tert-butylphenyl) phosphite, content 99%, acid value ≤ 0.5mgKOH / g; polyethylene wax is low molecular weight Polyethylene wax, molecular weight 2000-4000, melting point above 100°C, viscosity CPS140°C 40MAX; white oil is white mineral oil, kinematic viscosity (40°C) above 14.5mm2 / s, flash p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com