Rewinding shaft for electrolytic copper foil production and using method thereof

A technology of electrolytic copper foil and winding reel, which is applied in electrolytic process, electroforming, etc., can solve the problems of production waste, achieve the effects of reducing costs, improving product qualification rate, and eliminating the use of tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

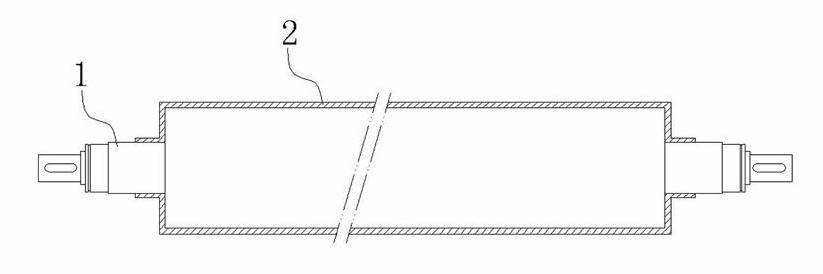

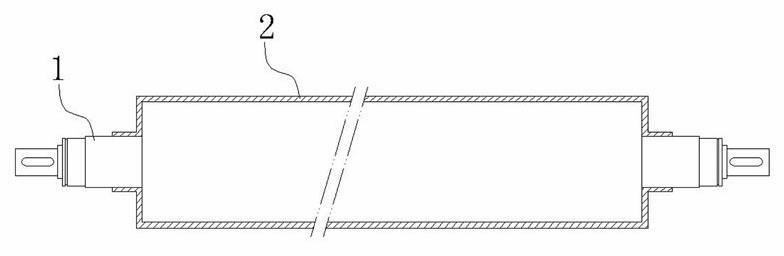

[0019] Refer to figure 1 As shown, a winding shaft for the production of electrolytic copper foil of the present invention includes a roller 1, and a rubber layer 2 is covered on the outer surface of the roller 1. The hardness (HA) of the rubber layer 2 is 80-90 degrees, and the roughness is 2~5μm, the rough surface can ensure that the copper foil can be stably pasted on the winding shaft; the thickness is 5~10mm; the rubber layer 2 is a corrosion-resistant rubber layer, which can be made of hydrogenated butadiene rubber or neoprene to extend it Service life.

[0020] The width of the rubber layer 2 must be greater than the width of the winding copper foil. Generally, the width of the cathode roller is 1400mm, and the width of the produced copper foil is also 1400mm. The roller specification of the winding shaft is Ф200*L1500mm. When working, the temperature of the winding shaft and the environment around the winding shaft must be kept below 80°C to ensure the service life of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com