Small-caliber aspherical composite precise processing method

A precision machining and aspheric surface technology, applied in the field of aspheric surface processing, can solve the problems of reducing processing efficiency, consuming auxiliary man-hours, and affecting processing accuracy, so as to prevent interference, reduce installation errors, and improve processing accuracy and processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

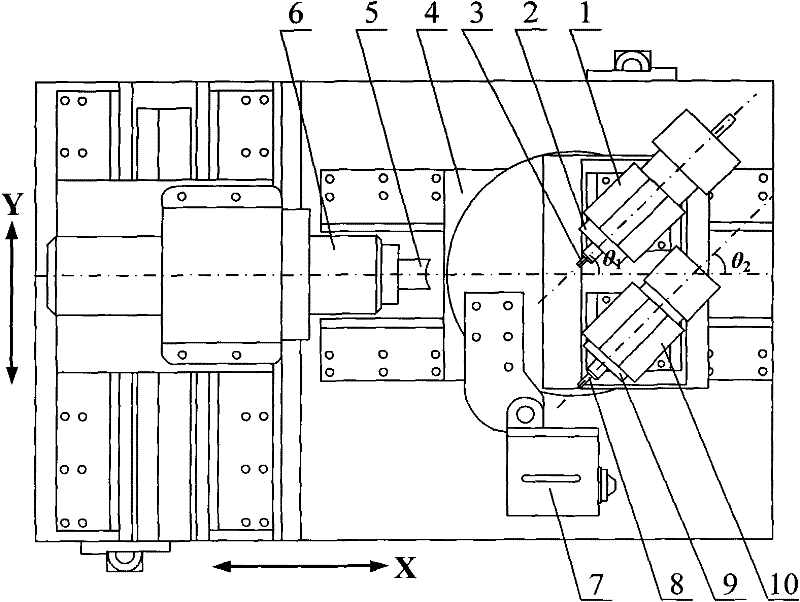

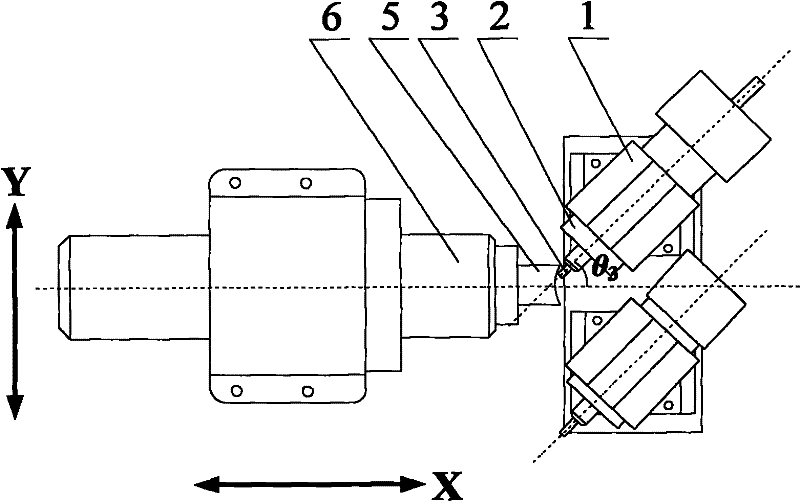

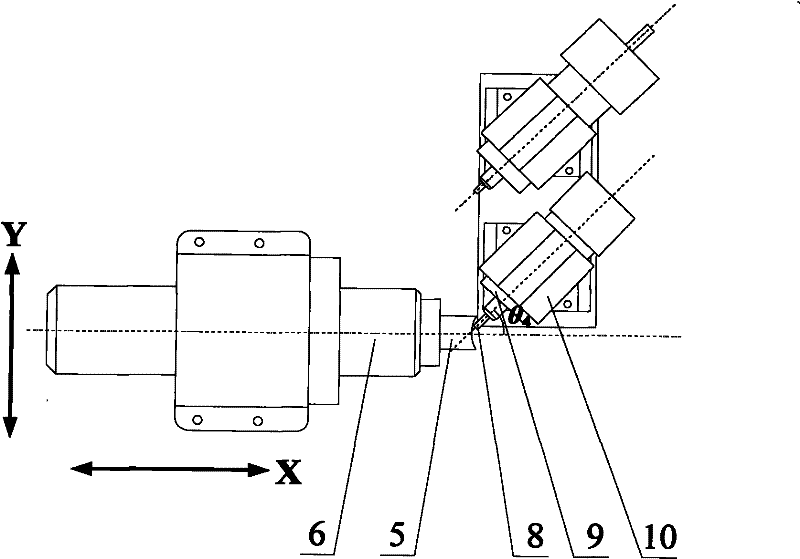

[0029] Embodiment 1: see attached Figure 1~4 ,

[0030] One, the workpiece 5 is clamped on a ULPG type precision machine tool manufactured by the Micro-Nano Manufacturing Research Institute of the National High-efficiency Grinding Engineering Technology Research Center of Hunan University in China, so that the grinding wheel spindle 2 axis of the oblique axis mirror grinding device 1 of the machine tool It is parallel to the axis spacing of the grinding head spindle 9 of the inclined-axis magneto-rheological polishing device 10 , and the two axes are equally spaced from the slide table 4 . The two axes and the axis of the workpiece spindle 6 successively form an equiangular angle ∠θ 1 and ∠θ 2 intersects, the ∠θ 1 and ∠θ 2 The angles are all 40°; then, the workpiece 5 and the micropowder grinding wheel 3 are centered using an optical magnifying glass. Then, the micropowder grinding wheel 3 is driven by the grinding wheel spindle 2 to perform oblique-axis grinding on the ...

Embodiment 2

[0033] Embodiment 2: see attached Figure 1~4 ,

[0034] 1. The workpiece 5 is clamped on the precision machine tool, and the axes of the grinding wheel main shaft 2 of the inclined-axis mirror grinding device 1 are parallel to the axis spacing of the grinding head main shaft 9 of the inclined-axis magnetorheological polishing device 10, and the The two axes are equally spaced from the slide table 4 . The two axes and the axis of the workpiece spindle 6 successively form an equiangular angle ∠θ 1 and ∠θ 2 intersects, the ∠θ 1 and ∠θ 2 The angles are all 50°; then, the workpiece 5 and the micropowder grinding wheel 3 are centered using an optical magnifying glass. Then, the micropowder grinding wheel 3 is driven by the grinding wheel spindle 2 to perform oblique-axis grinding on the aspherical surface of the workpiece 5 according to the set grinding track. During processing, the axis of the grinding wheel spindle 2 intersects the axis of the workpiece spindle 6 at an angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com