Method for improving yield of sintered square frame through hole type magnetic cores

A magnetic core and box technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as increased costs, inconsistent shrinkage rates, and abnormal dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

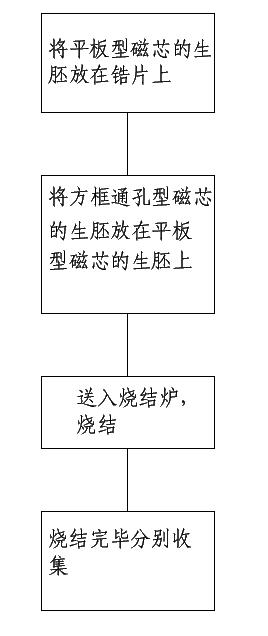

[0021] refer to figure 1 , a method for improving the yield rate of a sintered square frame through-hole magnetic core of the present invention is characterized in that, comprising the steps:

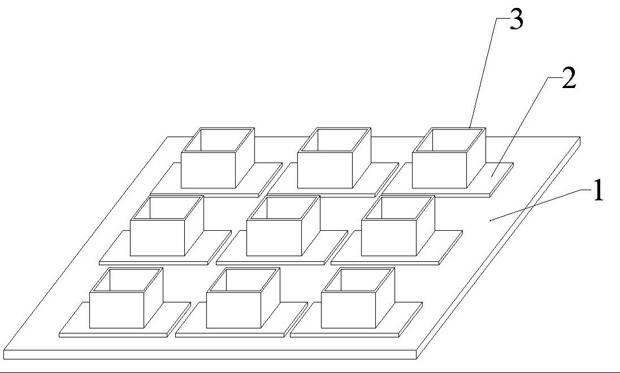

[0022] Step a: Place the green body 2 of the flat magnetic core to be sintered neatly on the zirconium chip 1 for loading, the material composition of the green body 2 of the flat magnetic core is the same as that of the square frame through-hole magnetic The material composition of the green embryo 3 of the core is the same;

[0023] Such as figure 2 As shown, the green body 2 of the planar magnetic core is placed flat on the zirconium sheet 1, which has the advantage of providing a larger loading area for the green body 3 of the square frame through-hole magnetic core, and at the same time, the stacking is stable.

[0024] Step b: placing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com